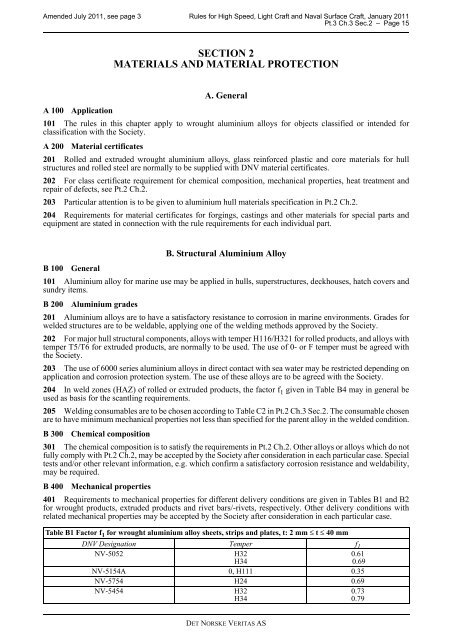

Amended July 2011, see page 3 Rules for High Speed, Light Craft and Naval Surface Craft, January 2011Pt.3 Ch.3 Sec.2 – Page 15SECTION 2MATERIALS AND MATERIAL PROTECTIONA. GeneralA 100 Application101 The rules in this chapter apply to wrought aluminium alloys for objects classified or intended forclassification with the Society.A 200 Material certificates201 Rolled and extruded wrought aluminium alloys, glass reinforced plastic and core materials for hullstructures and rolled steel are normally to be supplied with <strong>DNV</strong> material certificates.202 For class certificate requirement for chemical composition, mechanical properties, heat treatment andrepair of defects, see Pt.2 Ch.2.203 Particular attention is to be given to aluminium hull materials specification in Pt.2 Ch.2.204 Requirements for material certificates for forgings, castings and other materials for special parts andequipment are stated in connection with the rule requirements for each individual part.B. Structural Aluminium AlloyB 100 General101 Aluminium alloy for marine use may be applied in hulls, superstructures, deckhouses, hatch covers andsundry items.B 200 Aluminium grades201 Aluminium alloys are to have a satisfactory resistance to corrosion in marine environments. Grades forwelded structures are to be weldable, applying one of the welding methods approved by the Society.202 For major hull structural components, alloys with temper H116/H321 for rolled products, and alloys withtemper T5/T6 for extruded products, are normally to be used. The use of 0- or F temper must be agreed withthe Society.203 The use of 6000 series aluminium alloys in direct contact with sea water may be restricted depending onapplication and corrosion protection system. The use of these alloys are to be agreed with the Society.204 In weld zones (HAZ) of rolled or extruded products, the factor f 1 given in Table B4 may in general beused as basis for the scantling requirements.205 Welding consumables are to be chosen according to Table C2 in Pt.2 Ch.3 Sec.2. The consumable chosenare to have minimum mechanical properties not less than specified for the parent alloy in the welded condition.B 300 Chemical composition301 The chemical composition is to satisfy the requirements in Pt.2 Ch.2. Other alloys or alloys which do notfully comply with Pt.2 Ch.2, may be accepted by the Society after consideration in each particular case. Specialtests and/or other relevant information, e.g. which confirm a satisfactory corrosion resistance and weldability,may be required.B 400 Mechanical properties401 Requirements to mechanical properties for different delivery conditions are given in Tables B1 and B2for wrought products, extruded products and rivet bars/-rivets, respectively. Other delivery conditions withrelated mechanical properties may be accepted by the Society after consideration in each particular case.Table B1 Factor f 1 for wrought aluminium alloy sheets, strips and plates, t: 2 mm ≤ t ≤ 40 mm<strong>DNV</strong> <strong>Design</strong>ation Temper f 1NV-5052H32H340.610.69NV-5154A 0, H111 0.35NV-5754 H24 0.69NV-5454H32H340.730.79<strong>DET</strong> <strong>NORSKE</strong> <strong>VERITAS</strong> AS

Rules for High Speed, Light Craft and Naval Surface Craft, January 2011 Amended July 2011, see page 3Pt.3 Ch.3 Sec.2 – Page 16Table B1 Factor f 1 for wrought aluminium alloy sheets, strips and plates, t: 2 mm ≤ t ≤ 40 mm (Continued)<strong>DNV</strong> <strong>Design</strong>ation Temper f 1V-5086 H116, H32H340.800.88NV-5083 H116, H321 0.89NV-5383 H116, H34 0.89Note: For tempers 0 and H111, the factor f 1 is to be taken from Table B4.Table B2 Factor f 1 for extruded aluminium alloy profiles, rods and tubes, t: 2 mm ≤ t ≤ 25 mm<strong>DNV</strong>Temper<strong>Design</strong>ationf 1NV-6060 T5 0.55NV-6061T4T5/T60.460.76NV-6063T5T60.440.60NV-6005A T5/T6 0.76NV-6082T4T5/T60.460.90Note: Table B2 only applies when the main loading direction is logitudinal to the extrusion, see also Table B3.Table B3 Factor f 1 for extruded aluminium alloy profiles, rods and tubes, t: 2 mm ≤ t ≤ 25 mm, transverse toextruding direction<strong>DNV</strong><strong>Design</strong>ationTemper f 1NV-6060 T5 0.51NV-6061T4T5/T60.460.71NV-6005AT5/T66 < t < 1010 < t < 250.760.67NV-6082 T5 / T6 0.85Note: Table B2 only applies when the main loading direction is logitudinal to the extrusionTable B4 Factor f 1 in the welded condition<strong>DNV</strong>Temper Filler<strong>Design</strong>ationf 1NV-5052 0, H111, H32, H34 5356 0.27NV-5154A 0, H111 5356-5183 0.35NV 5754 0, H111, H24 5356-5183 0.33NV 5454 0, H111, H32, H34 5356-5183 0.35NV-5086 0, H111, H116, H32, H34 5356-5183 0.42NV-5083H116, H321H116, H321535651830.53 1)0.60 1)NV-5383 H116, H34 5183 0.64 2)NV-6060 T5 5356-5183 0.27NV-6061T4T5/T65356-5183 0.480.48NV-6063T55356-5183 0.27T6NV-6005A T5/T6 5356-5183 0.48NV-6082T4T5/T65356-5183 0.460.481) The utilisation of the material is higher than given by the f 1 factor as given in Sec. 1 A. This is due to extendedutilisation in Rules for HS, LC and NSC, f 1 =(σ 1 /240) x 1.102) The utilisation of the material is higher than given by the f 1 factor as given in Sec. 1 A. This is due to extendedutilisation in Rules for HS, LC and NSC, f 1 =(σ 1 /240) x 1.10<strong>DET</strong> <strong>NORSKE</strong> <strong>VERITAS</strong> AS

- Page 1 and 2: RULESDET NORSKE VERITAS (DNV)= STRU

- Page 3 and 4: FOREWORDDET NORSKE VERITAS (DNV) is

- Page 5 and 6: Rules for High Speed, Light Craft a

- Page 7 and 8: Rules for High Speed, Light Craft a

- Page 9 and 10: Rules for High Speed, Light Craft a

- Page 11 and 12: Rules for High Speed, Light Craft a

- Page 13 and 14: Rules for High Speed, Light Craft a

- Page 15 and 16: Rules for High Speed, Light Craft a

- Page 17 and 18: Rules for High Speed, Light Craft a

- Page 19 and 20: Rules for High Speed, Light Craft a

- Page 21 and 22: Rules for High Speed, Light Craft a

- Page 23 and 24: Rules for High Speed, Light Craft a

- Page 25 and 26: Rules for High Speed, Light Craft a

- Page 27 and 28: Rules for High Speed, Light Craft a

- Page 29 and 30: FOREWORDDET NORSKE VERITAS (DNV) is

- Page 31 and 32: Rules for High Speed, Light Craft a

- Page 33 and 34: Rules for High Speed, Light Craft a

- Page 35 and 36: Rules for High Speed, Light Craft a

- Page 37 and 38: Rules for High Speed, Light Craft a

- Page 39 and 40: Rules for High Speed, Light Craft a

- Page 41: Rules for High Speed, Light Craft a

- Page 45 and 46: Rules for High Speed, Light Craft a

- Page 47 and 48: Rules for High Speed, Light Craft a

- Page 49 and 50: Rules for High Speed, Light Craft a

- Page 51 and 52: Rules for High Speed, Light Craft a

- Page 53 and 54: Rules for High Speed, Light Craft a

- Page 55 and 56: Rules for High Speed, Light Craft a

- Page 57 and 58: Rules for High Speed, Light Craft a

- Page 59 and 60: Rules for High Speed, Light Craft a

- Page 61 and 62: Rules for High Speed, Light Craft a

- Page 63 and 64: Rules for High Speed, Light Craft a

- Page 65 and 66: Rules for High Speed, Light Craft a

- Page 67 and 68: Rules for High Speed, Light Craft a

- Page 69 and 70: Rules for High Speed, Light Craft a

- Page 71 and 72: Rules for High Speed, Light Craft a

- Page 73 and 74: Rules for High Speed, Light Craft a

- Page 75 and 76: Rules for High Speed, Light Craft a

- Page 77 and 78: Rules for High Speed, Light Craft a

- Page 79 and 80: Rules for High Speed, Light Craft a

- Page 81 and 82: Rules for High Speed, Light Craft a

- Page 83: Rules for High Speed, Light Craft a