You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

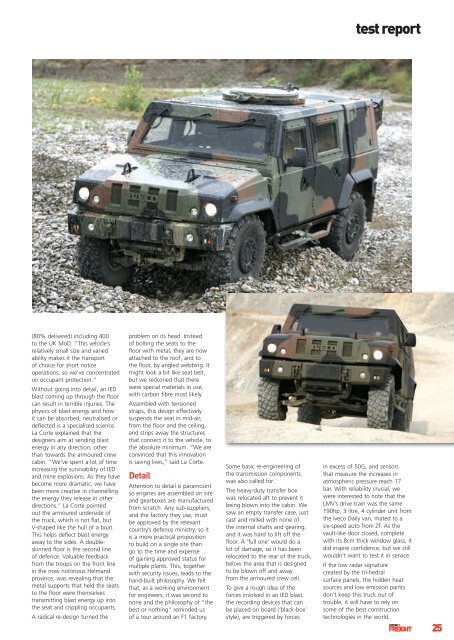

test report(80% delivered) including 400to the UK MoD. “This vehicle’srelatively small size and variedability makes it the transportof choice for short noticeoperations, so we’ve concentratedon occupant protection.”Without going into detail, an IEDblast coming up through the floorcan result in terrible injuries. Thephysics of blast energy and howit can be absorbed, neutralised ordeflected is a specialised science.La Corte explained that thedesigners aim at sending blastenergy in any direction, otherthan towards the armoured crewcabin. “We’ve spent a lot of timeincreasing the survivability of IEDand mine explosions. As they havebecome more dramatic, we havebeen more creative in channellingthe energy they release in otherdirections.” La Corte pointedout the armoured underside ofthe truck, which is not flat, butV-shaped like the hull of a boat.This helps deflect blast energyaway to the sides. A doubleskinnedfloor is the second lineof defence. Valuable feedbackfrom the troops on the front linein the now notorious Helmandprovince, was revealing that themetal supports that held the seatsto the floor were themselvestransmitting blast energy up intothe seat and crippling occupants.A radical re-design turned theproblem on its head. Insteadof bolting the seats to thefloor with metal, they are nowattached to the roof, and tothe floor, by angled webbing. Itmight look a bit like seat belt,but we reckoned that therewere special materials in use,with carbon fibre most likely.Assembled with tensionedstraps, this design effectivelysuspends the seat in mid-air,from the floor and the ceiling,and strips away the structuresthat connect it to the vehicle, tothe absolute minimum. “We areconvinced that this innovationis saving lives,” said La Corte.DetailAttention to detail is paramountso engines are assembled on siteand gearboxes are manufacturedfrom scratch. Any sub-suppliers,and the factory they use, mustbe approved by the relevantcountry’s defence ministry, so itis a more practical propositionto build on a single site thango to the time and expenseof gaining approved status formultiple plants. This, togetherwith security issues, leads to thehand-built philosophy. We feltthat, as a working environmentfor engineers, it was second tonone and the philosophy of “thebest or nothing” reminded usof a tour around an F1 factory.Some basic re-engineering ofthe transmission componentswas also called for.The heavy-duty transfer boxwas relocated aft to prevent itbeing blown into the cabin. Wesaw an empty transfer case, justcast and milled with none ofthe internal shafts and gearing,and it was hard to lift off thefloor. A ‘full one‘ would do alot of damage, so it has beenrelocated to the rear of the truck,below the area that is designedto be blown off and awayfrom the armoured crew cell.To give a rough idea of theforces involved in an IED blast,the recording devices that canbe placed on board (‘black-box’style), are triggered by forcesin excess of 50G, and sensorsthat measure the increases inatmospheric pressure reach 17bar. With reliability crucial, wewere interested to note that theLMV’s drive train was the same190hp, 3 litre, 4 cylinder unit fromthe Iveco Daily van, mated to asix-speed auto from ZF. As thevault-like door closed, completewith its 8cm thick window glass, itdid inspire confidence, but we stillwouldn’t want to test it in service.If the low radar signaturecreated by the tri-hedralsurface panels, the hidden heatsources and low emission paintsdon’t keep this truck out oftrouble, it will have to rely onsome of the best constructiontechnologies in the world.25Iveco Defence Spread.indd 25 09/05/2012 10:58