DateLaboratory Testing of Portland Cement Concrete Patch Material ...

DateLaboratory Testing of Portland Cement Concrete Patch Material ...

DateLaboratory Testing of Portland Cement Concrete Patch Material ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

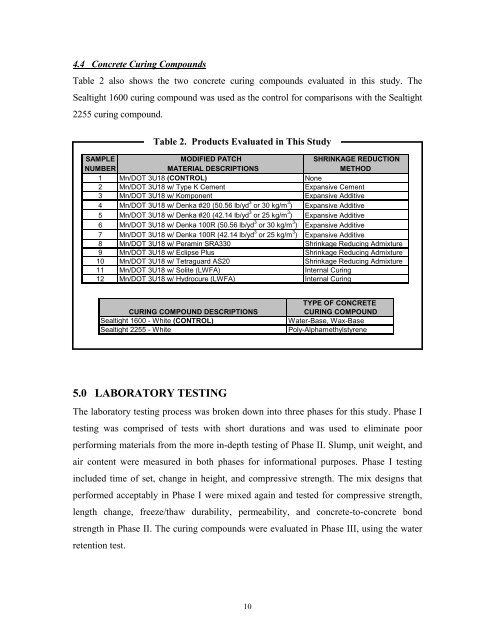

4.4 <strong>Concrete</strong> Curing CompoundsTable 2 also shows the two concrete curing compounds evaluated in this study. TheSealtight 1600 curing compound was used as the control for comparisons with the Sealtight2255 curing compound.Table 2. Products Evaluated in This StudySAMPLE MODIFIED PATCH SHRINKAGE REDUCTIONNUMBER MATERIAL DESCRIPTIONS METHOD1 Mn/DOT 3U18 (CONTROL) None2 Mn/DOT 3U18 w/ Type K <strong>Cement</strong> Expansive <strong>Cement</strong>3 Mn/DOT 3U18 w/ Komponent Expansive Additive4 Mn/DOT 3U18 w/ Denka #20 (50.56 lb/yd 3 or 30 kg/m 3 ) Expansive Additive5 Mn/DOT 3U18 w/ Denka #20 (42.14 lb/yd 3 or 25 kg/m 3 ) Expansive Additive6 Mn/DOT 3U18 w/ Denka 100R (50.56 lb/yd 3 or 30 kg/m 3 ) Expansive Additive7 Mn/DOT 3U18 w/ Denka 100R (42.14 lb/yd 3 or 25 kg/m 3 ) Expansive Additive8 Mn/DOT 3U18 w/ Peramin SRA330 Shrinkage Reducing Admixture9 Mn/DOT 3U18 w/ Eclipse Plus Shrinkage Reducing Admixture10 Mn/DOT 3U18 w/ Tetraguard AS20 Shrinkage Reducing Admixture11 Mn/DOT 3U18 w/ Solite (LWFA) Internal Curing12 Mn/DOT 3U18 w/ Hydrocure (LWFA) Internal CuringCURING COMPOUND DESCRIPTIONSSealtight 1600 - White (CONTROL)Sealtight 2255 - WhiteTYPE OF CONCRETECURING COMPOUNDWater-Base, Wax-BasePoly-Alphamethylstyrene5.0 LABORATORY TESTINGThe laboratory testing process was broken down into three phases for this study. Phase Itesting was comprised <strong>of</strong> tests with short durations and was used to eliminate poorperforming materials from the more in-depth testing <strong>of</strong> Phase II. Slump, unit weight, andair content were measured in both phases for informational purposes. Phase I testingincluded time <strong>of</strong> set, change in height, and compressive strength. The mix designs thatperformed acceptably in Phase I were mixed again and tested for compressive strength,length change, freeze/thaw durability, permeability, and concrete-to-concrete bondstrength in Phase II. The curing compounds were evaluated in Phase III, using the waterretention test.10