DateLaboratory Testing of Portland Cement Concrete Patch Material ...

DateLaboratory Testing of Portland Cement Concrete Patch Material ...

DateLaboratory Testing of Portland Cement Concrete Patch Material ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

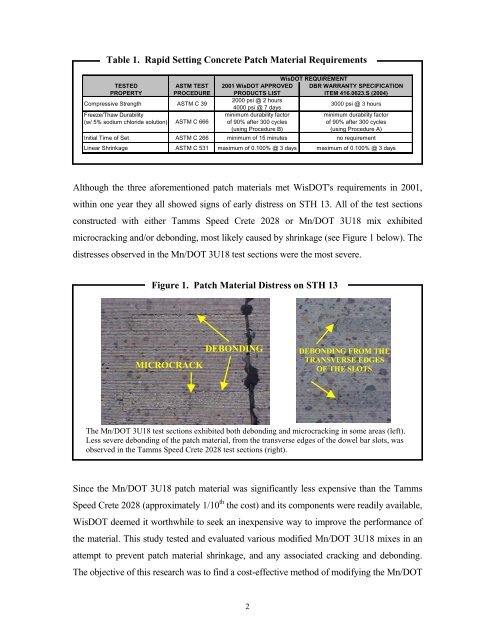

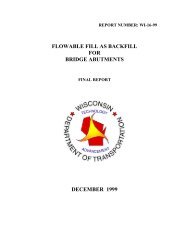

Table 1. Rapid Setting <strong>Concrete</strong> <strong>Patch</strong> <strong>Material</strong> RequirementsWisDOT REQUIREMENTTESTED ASTM TEST 2001 WisDOT APPROVED DBR WARRANTY SPECIFICATIONPROPERTY PROCEDURE PRODUCTS LIST ITEM 416.0623.S (2004)Compressive Strength ASTM C 392000 psi @ 2 hours4000 psi @ 7 days3000 psi @ 3 hoursFreeze/Thaw Durability minimum durability factor minimum durability factor(w/ 5% sodium chloride solution) ASTM C 666 <strong>of</strong> 90% after 300 cycles <strong>of</strong> 90% after 300 cycles(using Procedure B) (using Procedure A)Initial Time <strong>of</strong> Set ASTM C 266 minimum <strong>of</strong> 15 minutes no requirementLinear Shrinkage ASTM C 531 maximum <strong>of</strong> 0.100% @ 3 days maximum <strong>of</strong> 0.100% @ 3 daysAlthough the three aforementioned patch materials met WisDOT's requirements in 2001,within one year they all showed signs <strong>of</strong> early distress on STH 13. All <strong>of</strong> the test sectionsconstructed with either Tamms Speed Crete 2028 or Mn/DOT 3U18 mix exhibitedmicrocracking and/or debonding, most likely caused by shrinkage (see Figure 1 below). Thedistresses observed in the Mn/DOT 3U18 test sections were the most severe.Figure 1. <strong>Patch</strong> <strong>Material</strong> Distress on STH 13MICROCRACKDEBONDINGDEBONDING FROM THETRANSVERSE EDGESOF THE SLOTSThe Mn/DOT 3U18 test sections exhibited both debonding and microcracking in some areas (left).Less severe debonding <strong>of</strong> the patch material, from the transverse edges <strong>of</strong> the dowel bar slots, wasobserved in the Tamms Speed Crete 2028 test sections (right).Since the Mn/DOT 3U18 patch material was significantly less expensive than the TammsSpeed Crete 2028 (approximately 1/10 th the cost) and its components were readily available,WisDOT deemed it worthwhile to seek an inexpensive way to improve the performance <strong>of</strong>the material. This study tested and evaluated various modified Mn/DOT 3U18 mixes in anattempt to prevent patch material shrinkage, and any associated cracking and debonding.The objective <strong>of</strong> this research was to find a cost-effective method <strong>of</strong> modifying the Mn/DOT2