DateLaboratory Testing of Portland Cement Concrete Patch Material ...

DateLaboratory Testing of Portland Cement Concrete Patch Material ...

DateLaboratory Testing of Portland Cement Concrete Patch Material ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

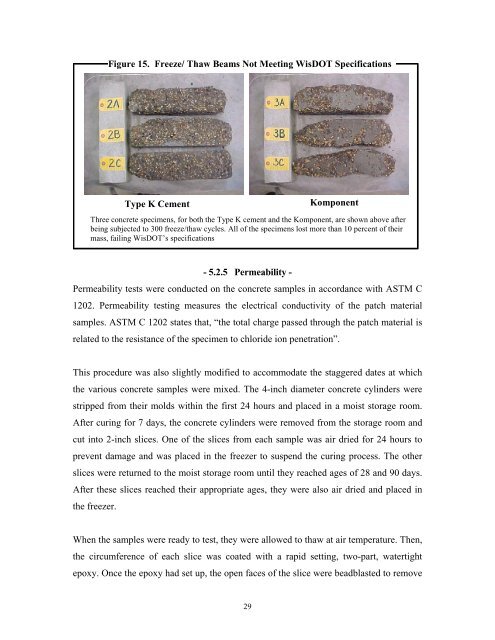

Figure 15. Freeze/ Thaw Beams Not Meeting WisDOT SpecificationsType K <strong>Cement</strong>KomponentThree concrete specimens, for both the Type K cement and the Komponent, are shown above afterbeing subjected to 300 freeze/thaw cycles. All <strong>of</strong> the specimens lost more than 10 percent <strong>of</strong> theirmass, failing WisDOT’s specifications- 5.2.5 Permeability -Permeability tests were conducted on the concrete samples in accordance with ASTM C1202. Permeability testing measures the electrical conductivity <strong>of</strong> the patch materialsamples. ASTM C 1202 states that, “the total charge passed through the patch material isrelated to the resistance <strong>of</strong> the specimen to chloride ion penetration”.This procedure was also slightly modified to accommodate the staggered dates at whichthe various concrete samples were mixed. The 4-inch diameter concrete cylinders werestripped from their molds within the first 24 hours and placed in a moist storage room.After curing for 7 days, the concrete cylinders were removed from the storage room andcut into 2-inch slices. One <strong>of</strong> the slices from each sample was air dried for 24 hours toprevent damage and was placed in the freezer to suspend the curing process. The otherslices were returned to the moist storage room until they reached ages <strong>of</strong> 28 and 90 days.After these slices reached their appropriate ages, they were also air dried and placed inthe freezer.When the samples were ready to test, they were allowed to thaw at air temperature. Then,the circumference <strong>of</strong> each slice was coated with a rapid setting, two-part, watertightepoxy. Once the epoxy had set up, the open faces <strong>of</strong> the slice were beadblasted to remove29