BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

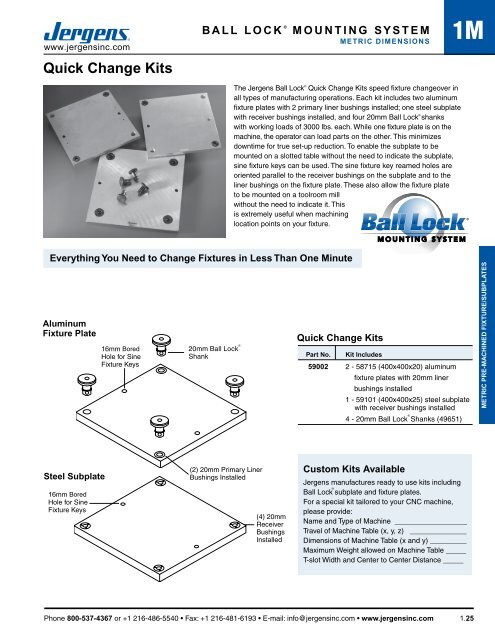

www.jergensinc.com<strong>BALL</strong> <strong>LOCK</strong> ®<strong>MOUNTING</strong> <strong>SYSTEM</strong>METRIC DIMENSIONS1MQuick Change KitsThe <strong>Jergens</strong> Ball Lock ® Quick Change Kits speed fixture changeover inall types of manufacturing operations. Each kit includes two aluminumfixture plates with 2 primary liner bushings installed; one steel subplatewith receiver bushings installed, and four 20mm Ball Lock ® shankswith working loads of 3000 lbs. each. While one fixture plate is on themachine, the operator can load parts on the other. This minimizesdowntime for true set-up reduction. To enable the subplate to bemounted on a slotted table without the need to indicate the subplate,sine fixture keys can be used. The sine fixture key reamed holes areoriented parallel to the receiver bushings on the subplate and to theliner bushings on the fixture plate. These also allow the fixture plateto be mounted on a toolroom millwithout the need to indicate it. Thisis extremely useful when machininglocation points on your fixture.Everything You Need to Change Fixtures in Less Than One MinuteAluminumFixture Plate16mm BoredHole for SineFixture Keys20mm Ball Lock ®ShankQuick Change KitsPart No.Kit <strong>Inc</strong>ludes59002 2 - 58715 (400x400x20) aluminumfixture plates with 20mm linerbushings installed1 - 59101 (400x400x25) steel subplatewith receiver bushings installed4 - 20mm Ball Lock ® Shanks (49651)METRIC PRE-MACHINED FIXTURE/SUBPLATESSteel Subplate16mm BoredHole for SineFixture Keys(2) 20mm Primary LinerBushings Installed(4) 20mmReceiverBushingsInstalledCustom Kits Available<strong>Jergens</strong> manufactures ready to use kits includingBall Lock ® subplate and fixture plates.For a special kit tailored to your CNC machine,please provide:Name and Type of Machine __________________Travel of Machine Table (x, y, z) ______________Dimensions of Machine Table (x and y) _________Maximum Weight allowed on Machine Table _____T-slot Width and Center to Center Distance _____Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.25