BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

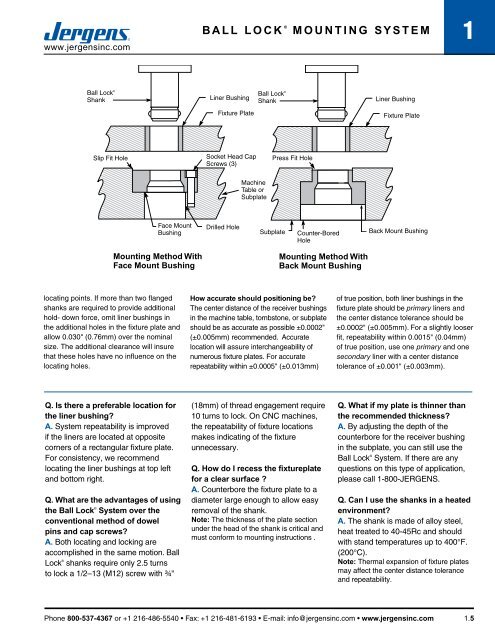

www.jergensinc.com<strong>BALL</strong> <strong>LOCK</strong> ®<strong>MOUNTING</strong> <strong>SYSTEM</strong>1Ball Lock ®ShankLiner BushingBall Lock ®ShankLiner BushingFixture PlateFixture PlateSlip Fit HoleSocket Head CapScrews (3)Press Fit HoleMachineTable orSubplateFace MountBushingDrilled HoleSubplateCounter-BoredHoleBack Mount BushingMounting Method WithFace Mount BushingMounting Method WithBack Mount Bushinglocating points. If more than two flangedshanks are required to provide additionalhold- down force, omit liner bushings inthe additional holes in the fixture plate andallow 0.030" (0.76mm) over the nominalsize. The additional clearance will insurethat these holes have no influence on thelocating holes.How accurate should positioning be?The center distance of the receiver bushingsin the machine table, tombstone, or subplateshould be as accurate as possible ±0.0002"(±0.005mm) recommended. Accuratelocation will assure interchangeability ofnumerous fixture plates. For accuraterepeatability within ±0.0005" (±0.013mm)of true position, both liner bushings in thefixture plate should be primary liners andthe center distance tolerance should be±0.0002" (±0.005mm). For a slightly looserfit, repeatability within 0.0015" (0.04mm)of true position, use one primary and onesecondary liner with a center distancetolerance of ±0.001" (±0.003mm).Q. Is there a preferable location forthe liner bushing?A. System repeatability is improvedif the liners are located at oppositecorners of a rectangular fixture plate.For consistency, we recommendlocating the liner bushings at top leftand bottom right.Q. What are the advantages of usingthe Ball Lock ® System over theconventional method of dowelpins and cap screws?A. Both locating and locking areaccomplished in the same motion. BallLock ® shanks require only 2.5 turnsto lock a 1/2–13 (M12) screw with ¾"(18mm) of thread engagement require10 turns to lock. On CNC machines,the repeatability of fixture locationsmakes indicating of the fixtureunnecessary.Q. How do I recess the fixtureplatefor a clear surface ?A. Counterbore the fixture plate to adiameter large enough to allow easyremoval of the shank.Note: The thickness of the plate sectionunder the head of the shank is critical andmust conform to mounting instructions .Q. What if my plate is thinner thanthe recommended thickness?A. By adjusting the depth of thecounterbore for the receiver bushingin the subplate, you can still use theBall Lock ® System. If there are anyquestions on this type of application,please call 1-800-JERGENS.Q. Can I use the shanks in a heatedenvironment?A. The shank is made of alloy steel,heat treated to 40-45Rc and shouldwith stand temperatures up to 400°F.(200°C).Note: Thermal expansion of fixture platesmay affect the center distance toleranceand repeatability.Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.5