SERVICE HANDBOOK

SERVICE HANDBOOK

SERVICE HANDBOOK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

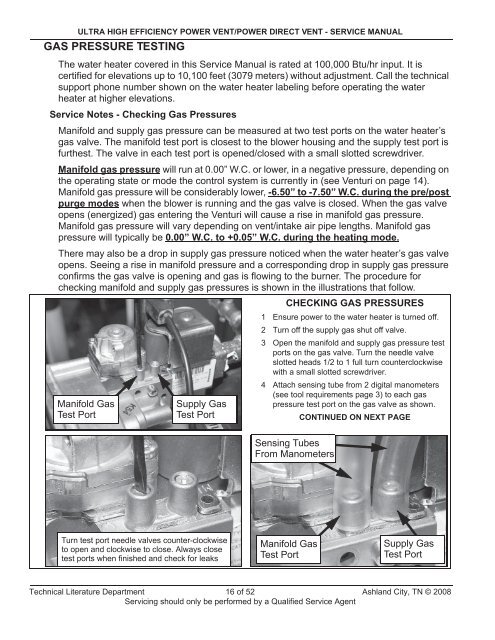

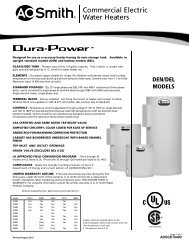

ULTRA HIGH EFFICIENCY POWER VENT/POWER DIRECT VENT - <strong>SERVICE</strong> MANUALGAS PRESSURE TESTINGThe water heater covered in this Service Manual is rated at 100,000 Btu/hr input. It iscertified for elevations up to 10,100 feet (3079 meters) without adjustment. Call the technicalsupport phone number shown on the water heater labeling before operating the waterheater at higher elevations.Service Notes - Checking Gas PressuresManifold and supply gas pressure can be measured at two test ports on the water heater’sgas valve. The manifold test port is closest to the blower housing and the supply test port isfurthest. The valve in each test port is opened/closed with a small slotted screwdriver.Manifold gas pressure will run at 0.00” W.C. or lower, in a negative pressure, depending onthe operating state or mode the control system is currently in (see Venturi on page 14).Manifold gas pressure will be considerably lower, -6.50” to -7.50” W.C. during the pre/postpurge modes when the blower is running and the gas valve is closed. When the gas valveopens (energized) gas entering the Venturi will cause a rise in manifold gas pressure.Manifold gas pressure will vary depending on vent/intake air pipe lengths. Manifold gaspressure will typically be 0.00” W.C. to +0.05” W.C. during the heating mode.There may also be a drop in supply gas pressure noticed when the water heater’s gas valveopens. Seeing a rise in manifold pressure and a corresponding drop in supply gas pressureconfirms the gas valve is opening and gas is flowing to the burner. The procedure forchecking manifold and supply gas pressures is shown in the illustrations that follow.CHECKING GAS PRESSURESManifold GasTest PortSupply GasTest Port1 Ensure power to the water heater is turned off.2 Turn off the supply gas shut off valve.3 Open the manifold and supply gas pressure testports on the gas valve. Turn the needle valveslotted heads 1/2 to 1 full turn counterclockwisewith a small slotted screwdriver.4 Attach sensing tube from 2 digital manometers(see tool requirements page 3) to each gaspressure test port on the gas valve as shown.CONTINUED ON NEXT PAGESensing TubesFrom ManometersTurn test port needle valves counter-clockwiseto open and clockwise to close. Always closetest ports when finished and check for leaksManifold GasTest PortSupply GasTest PortTechnical Literature Department 16 of 52 Ashland City, TN © 2008Servicing should only be performed by a Qualified Service Agent