SERVICE HANDBOOK

SERVICE HANDBOOK

SERVICE HANDBOOK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

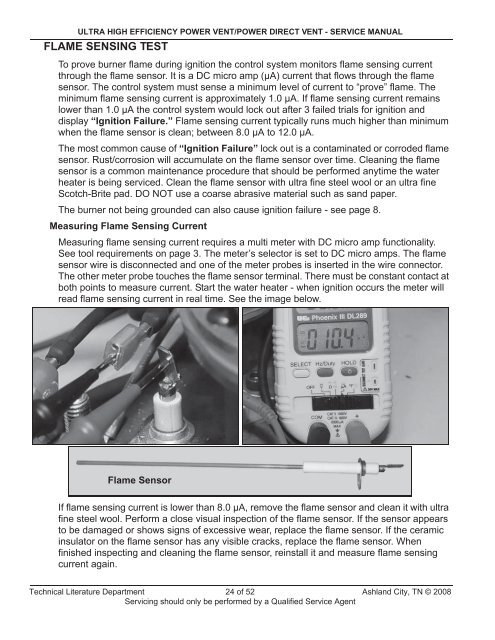

ULTRA HIGH EFFICIENCY POWER VENT/POWER DIRECT VENT - <strong>SERVICE</strong> MANUALFLAME SENSING TESTTo prove burner flame during ignition the control system monitors flame sensing currentthrough the flame sensor. It is a DC micro amp (μA) current that flows through the flamesensor. The control system must sense a minimum level of current to “prove” flame. Theminimum flame sensing current is approximately 1.0 μA. If flame sensing current remainslower than 1.0 μA the control system would lock out after 3 failed trials for ignition anddisplay “Ignition Failure.” Flame sensing current typically runs much higher than minimumwhen the flame sensor is clean; between 8.0 μA to 12.0 μA.The most common cause of “Ignition Failure” lock out is a contaminated or corroded flamesensor. Rust/corrosion will accumulate on the flame sensor over time. Cleaning the flamesensor is a common maintenance procedure that should be performed anytime the waterheater is being serviced. Clean the flame sensor with ultra fine steel wool or an ultra fineScotch-Brite pad. DO NOT use a coarse abrasive material such as sand paper.The burner not being grounded can also cause ignition failure - see page 8.Measuring Flame Sensing CurrentMeasuring flame sensing current requires a multi meter with DC micro amp functionality.See tool requirements on page 3. The meter’s selector is set to DC micro amps. The flamesensor wire is disconnected and one of the meter probes is inserted in the wire connector.The other meter probe touches the flame sensor terminal. There must be constant contact atboth points to measure current. Start the water heater - when ignition occurs the meter willread flame sensing current in real time. See the image below.Flame SensorIf flame sensing current is lower than 8.0 μA, remove the flame sensor and clean it with ultrafine steel wool. Perform a close visual inspection of the flame sensor. If the sensor appearsto be damaged or shows signs of excessive wear, replace the flame sensor. If the ceramicinsulator on the flame sensor has any visible cracks, replace the flame sensor. Whenfinished inspecting and cleaning the flame sensor, reinstall it and measure flame sensingcurrent again.Technical Literature Department 24 of 52 Ashland City, TN © 2008Servicing should only be performed by a Qualified Service Agent