SERVICE HANDBOOK

SERVICE HANDBOOK

SERVICE HANDBOOK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

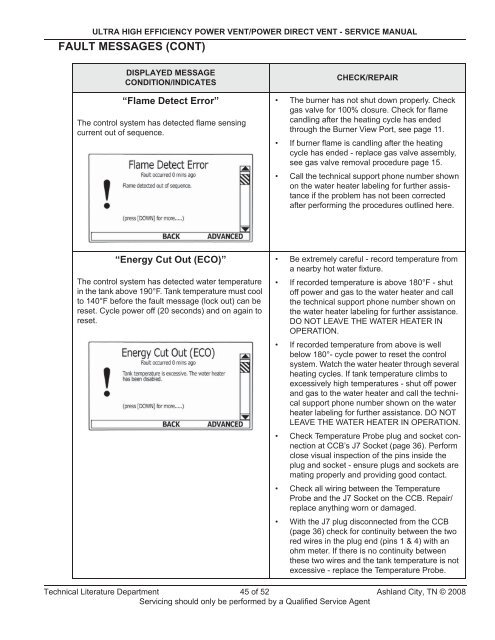

ULTRA HIGH EFFICIENCY POWER VENT/POWER DIRECT VENT - <strong>SERVICE</strong> MANUALFAULT MESSAGES (CONT)DISPLAYED MESSAGECONDITION/INDICATES“Flame Detect Error”The control system has detected flame sensingcurrent out of sequence.CHECK/REPAIR• The burner has not shut down properly. Checkgas valve for 100% closure. Check for flamecandling after the heating cycle has endedthrough the Burner View Port, see page 11.• If burner flame is candling after the heatingcycle has ended - replace gas valve assembly,see gas valve removal procedure page 15.• Call the technical support phone number shownon the water heater labeling for further assistanceif the problem has not been correctedafter performing the procedures outlined here.“Energy Cut Out (ECO)”The control system has detected water temperaturein the tank above 190°F. Tank temperature must coolto 140°F before the fault message (lock out) can bereset. Cycle power off (20 seconds) and on again toreset.• Be extremely careful - record temperature froma nearby hot water fixture.• If recorded temperature is above 180°F - shutoff power and gas to the water heater and callthe technical support phone number shown onthe water heater labeling for further assistance.DO NOT LEAVE THE WATER HEATER INOPERATION.• If recorded temperature from above is wellbelow 180°- cycle power to reset the controlsystem. Watch the water heater through severalheating cycles. If tank temperature climbs toexcessively high temperatures - shut off powerand gas to the water heater and call the technicalsupport phone number shown on the waterheater labeling for further assistance. DO NOTLEAVE THE WATER HEATER IN OPERATION.• Check Temperature Probe plug and socket connectionat CCB’s J7 Socket (page 36). Performclose visual inspection of the pins inside theplug and socket - ensure plugs and sockets aremating properly and providing good contact.• Check all wiring between the TemperatureProbe and the J7 Socket on the CCB. Repair/replace anything worn or damaged.• With the J7 plug disconnected from the CCB(page 36) check for continuity between the twored wires in the plug end (pins 1 & 4) with anohm meter. If there is no continuity betweenthese two wires and the tank temperature is notexcessive - replace the Temperature Probe.Technical Literature Department 45 of 52 Ashland City, TN © 2008Servicing should only be performed by a Qualified Service Agent