Socio-economic assessment and feasibility study on - Öko-Institut eV

Socio-economic assessment and feasibility study on - Öko-Institut eV

Socio-economic assessment and feasibility study on - Öko-Institut eV

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>Socio</str<strong>on</strong>g>-<str<strong>on</strong>g>ec<strong>on</strong>omic</str<strong>on</strong>g> <str<strong>on</strong>g>assessment</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>feasibility</str<strong>on</strong>g> <str<strong>on</strong>g>study</str<strong>on</strong>g><br />

<strong>on</strong> sustainable e-waste management in Ghana<br />

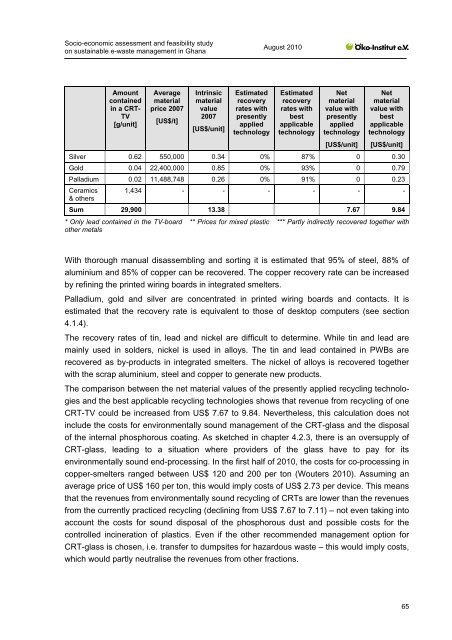

Amount<br />

c<strong>on</strong>tained<br />

in a CRT-<br />

TV<br />

[g/unit]<br />

Average<br />

material<br />

price 2007<br />

[US$/t]<br />

Intrinsic<br />

material<br />

value<br />

2007<br />

[US$/unit]<br />

Estimated<br />

recovery<br />

rates with<br />

presently<br />

applied<br />

technology<br />

August 2010<br />

Estimated<br />

recovery<br />

rates with<br />

best<br />

applicable<br />

technology<br />

Net<br />

material<br />

value with<br />

presently<br />

applied<br />

technology<br />

[US$/unit]<br />

Net<br />

material<br />

value with<br />

best<br />

applicable<br />

technology<br />

[US$/unit]<br />

Silver 0.62 550,000 0.34 0% 87% 0 0.30<br />

Gold 0.04 22,400,000 0.85 0% 93% 0 0.79<br />

Palladium 0.02 11,488,748 0.26 0% 91% 0 0.23<br />

Ceramics<br />

& others<br />

1,434 - - - - - -<br />

Sum 29,900 13.38 7.67 9.84<br />

* Only lead c<strong>on</strong>tained in the TV-board ** Prices for mixed plastic *** Partly indirectly recovered together with<br />

other metals<br />

With thorough manual disassembling <str<strong>on</strong>g>and</str<strong>on</strong>g> sorting it is estimated that 95% of steel, 88% of<br />

aluminium <str<strong>on</strong>g>and</str<strong>on</strong>g> 85% of copper can be recovered. The copper recovery rate can be increased<br />

by refining the printed wiring boards in integrated smelters.<br />

Palladium, gold <str<strong>on</strong>g>and</str<strong>on</strong>g> silver are c<strong>on</strong>centrated in printed wiring boards <str<strong>on</strong>g>and</str<strong>on</strong>g> c<strong>on</strong>tacts. It is<br />

estimated that the recovery rate is equivalent to those of desktop computers (see secti<strong>on</strong><br />

4.1.4).<br />

The recovery rates of tin, lead <str<strong>on</strong>g>and</str<strong>on</strong>g> nickel are difficult to determine. While tin <str<strong>on</strong>g>and</str<strong>on</strong>g> lead are<br />

mainly used in solders, nickel is used in alloys. The tin <str<strong>on</strong>g>and</str<strong>on</strong>g> lead c<strong>on</strong>tained in PWBs are<br />

recovered as by-products in integrated smelters. The nickel of alloys is recovered together<br />

with the scrap aluminium, steel <str<strong>on</strong>g>and</str<strong>on</strong>g> copper to generate new products.<br />

The comparis<strong>on</strong> between the net material values of the presently applied recycling technologies<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> the best applicable recycling technologies shows that revenue from recycling of <strong>on</strong>e<br />

CRT-TV could be increased from US$ 7.67 to 9.84. Nevertheless, this calculati<strong>on</strong> does not<br />

include the costs for envir<strong>on</strong>mentally sound management of the CRT-glass <str<strong>on</strong>g>and</str<strong>on</strong>g> the disposal<br />

of the internal phosphorous coating. As sketched in chapter 4.2.3, there is an oversupply of<br />

CRT-glass, leading to a situati<strong>on</strong> where providers of the glass have to pay for its<br />

envir<strong>on</strong>mentally sound end-processing. In the first half of 2010, the costs for co-processing in<br />

copper-smelters ranged between US$ 120 <str<strong>on</strong>g>and</str<strong>on</strong>g> 200 per t<strong>on</strong> (Wouters 2010). Assuming an<br />

average price of US$ 160 per t<strong>on</strong>, this would imply costs of US$ 2.73 per device. This means<br />

that the revenues from envir<strong>on</strong>mentally sound recycling of CRTs are lower than the revenues<br />

from the currently practiced recycling (declining from US$ 7.67 to 7.11) – not even taking into<br />

account the costs for sound disposal of the phosphorous dust <str<strong>on</strong>g>and</str<strong>on</strong>g> possible costs for the<br />

c<strong>on</strong>trolled incinerati<strong>on</strong> of plastics. Even if the other recommended management opti<strong>on</strong> for<br />

CRT-glass is chosen, i.e. transfer to dumpsites for hazardous waste – this would imply costs,<br />

which would partly neutralise the revenues from other fracti<strong>on</strong>s.<br />

65