Autumn

PDF6S01 - 2010Download - The Clancy Group Plc

PDF6S01 - 2010Download - The Clancy Group Plc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8 | <strong>Autumn</strong> Issue<br />

| SYSTEMS |<br />

Innovation<br />

Earlier this year we reported the<br />

creation of a new role within the<br />

business, that of Innovations<br />

Manager. The appointment was filled<br />

by Kevin Halpin.<br />

The appointment has brought a new<br />

dimension to the way in which we are<br />

capturing and driving innovation<br />

within the business.<br />

“We now have a much higher level of<br />

engagement with research and<br />

development within our supply chain,<br />

and are developing ideas and initiatives<br />

into viable proposals that potentially<br />

will offer value to the business.”<br />

To ensure that we are capitalising on<br />

innovation and best practice across<br />

all our contracts, and are therefore<br />

delivering best value to all our clients,<br />

we have formed a cross-company<br />

innovation forum. “The forum<br />

comprises of delegates from across<br />

the company sharing best practice<br />

through meetings, workshops and<br />

video conferencing.” stated Kevin.<br />

Kobus Pipe Puller<br />

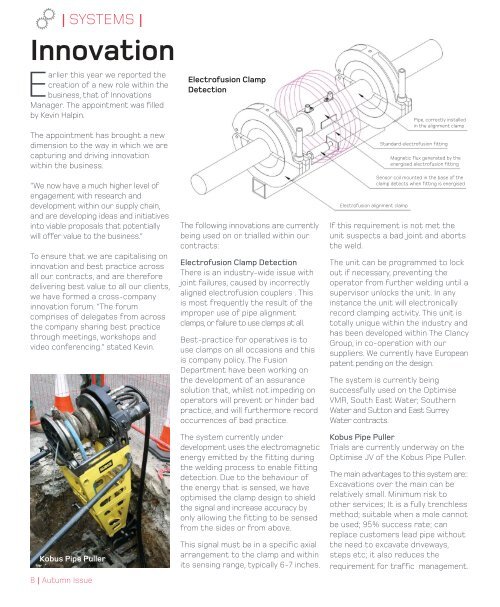

Electrofusion Clamp<br />

Detection<br />

The following innovations are currently<br />

being used on or trialled within our<br />

contracts:<br />

Electrofusion Clamp Detection<br />

There is an industry-wide issue with<br />

joint failures, caused by incorrectly<br />

aligned electrofusion couplers . This<br />

is most frequently the result of the<br />

improper use of pipe alignment<br />

clamps, or failure to use clamps at all.<br />

Best-practice for operatives is to<br />

use clamps on all occasions and this<br />

is company policy. The Fusion<br />

Department have been working on<br />

the development of an assurance<br />

solution that, whilst not impeding on<br />

operators will prevent or hinder bad<br />

practice, and will furthermore record<br />

occurrences of bad practice.<br />

The system currently under<br />

development uses the electromagnetic<br />

energy emitted by the fitting during<br />

the welding process to enable fitting<br />

detection. Due to the behaviour of<br />

the energy that is sensed, we have<br />

optimised the clamp design to shield<br />

the signal and increase accuracy by<br />

only allowing the fitting to be sensed<br />

from the sides or from above.<br />

This signal must be in a specific axial<br />

arrangement to the clamp and within<br />

its sensing range, typically 6-7 inches.<br />

Electrofusion alignment clamp<br />

Pipe, correctly installed<br />

in the alignment clamp<br />

Standard electrofusion fitting<br />

Magnetic flux generated by the<br />

energised electrofusion fitting<br />

Sensor coil mounted in the base of the<br />

clamp detects when fitting is energised<br />

If this requirement is not met the<br />

unit suspects a bad joint and aborts<br />

the weld.<br />

The unit can be programmed to lock<br />

out if necessary, preventing the<br />

operator from further welding until a<br />

supervisor unlocks the unit. In any<br />

instance the unit will electronically<br />

record clamping activity. This unit is<br />

totally unique within the industry and<br />

has been developed within The Clancy<br />

Group, in co-operation with our<br />

suppliers. We currently have European<br />

patent pending on the design.<br />

The system is currently being<br />

successfully used on the Optimise<br />

VMR, South East Water, Southern<br />

Water and Sutton and East Surrey<br />

Water contracts.<br />

Kobus Pipe Puller<br />

Trials are currently underway on the<br />

Optimise JV of the Kobus Pipe Puller.<br />

The main advantages to this system are::<br />

Excavations over the main can be<br />

relatively small. Minimum risk to<br />

other services; It is a fully trenchless<br />

method; suitable when a mole cannot<br />

be used; 95% success rate; can<br />

replace customers lead pipe without<br />

the need to excavate driveways,<br />

steps etc; it also reduces the<br />

requirement for traffic management.