Retired Racehorses

tfrr_reportandappendicesfinal

tfrr_reportandappendicesfinal

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Laboratory Performance Testing<br />

Composition testing has the distinct limitation that it only describes the material, not the results<br />

which occur from the composition of the material. For surfaces which may have unique local sand or<br />

clay, this is particularly problematic since the performance of the track may not be consistent with other<br />

tracks which have similar composition. As a result, there is a need for both laboratory performance<br />

testing to evaluate the performance of the components of the track material and to determine if the<br />

composition produces values similar to other racing surfaces. In addition the in‐situ performance testing<br />

should be used to describe the overall performance of the material when combined with the design of<br />

the track.<br />

Shear strength<br />

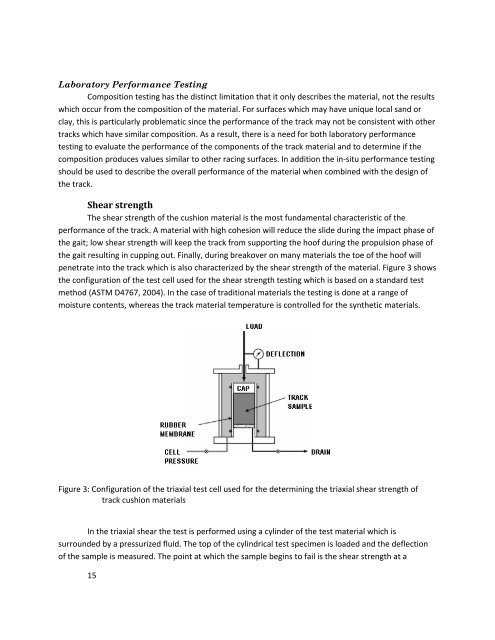

The shear strength of the cushion material is the most fundamental characteristic of the<br />

performance of the track. A material with high cohesion will reduce the slide during the impact phase of<br />

the gait; low shear strength will keep the track from supporting the hoof during the propulsion phase of<br />

the gait resulting in cupping out. Finally, during breakover on many materials the toe of the hoof will<br />

penetrate into the track which is also characterized by the shear strength of the material. Figure 3 shows<br />

the configuration of the test cell used for the shear strength testing which is based on a standard test<br />

method (ASTM D4767, 2004). In the case of traditional materials the testing is done at a range of<br />

moisture contents, whereas the track material temperature is controlled for the synthetic materials.<br />

Figure 3: Configuration of the triaxial test cell used for the determining the triaxial shear strength of<br />

track cushion materials<br />

In the triaxial shear the test is performed using a cylinder of the test material which is<br />

surrounded by a pressurized fluid. The top of the cylindrical test specimen is loaded and the deflection<br />

of the sample is measured. The point at which the sample begins to fail is the shear strength at a<br />

15