THE DATA FRONT

Download as PDF - Labels & Labeling

Download as PDF - Labels & Labeling

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

24 | new products<br />

NEW products<br />

6<br />

5<br />

Tag inserter for wet and dry inlays<br />

5 6<br />

Schober USA<br />

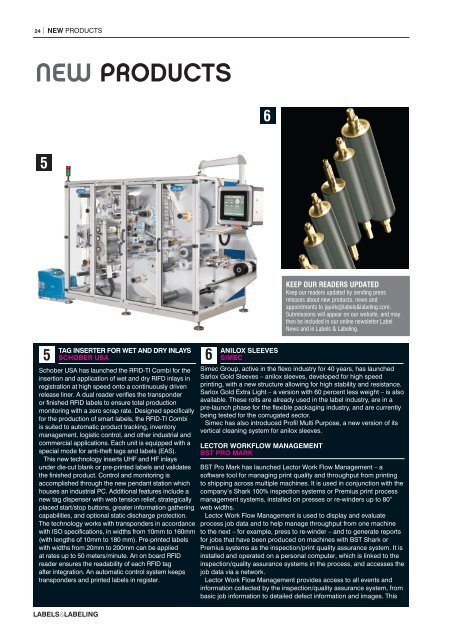

Schober USA has launched the RFID-TI Combi for the<br />

insertion and application of wet and dry RIFD inlays in<br />

registration at high speed onto a continuously driven<br />

release liner. A dual reader verifies the transponder<br />

or finished RFID labels to ensure total production<br />

monitoring with a zero scrap rate. Designed specifically<br />

for the production of smart labels, the RFID-TI Combi<br />

is suited to automatic product tracking, inventory<br />

management, logistic control, and other industrial and<br />

commercial applications. Each unit is equipped with a<br />

special mode for anti-theft tags and labels (EAS).<br />

This new technology inserts UHF and HF inlays<br />

under die-cut blank or pre-printed labels and validates<br />

the finished product. Control and monitoring is<br />

accomplished through the new pendant station which<br />

houses an industrial PC. Additional features include a<br />

new tag dispenser with web tension relief, strategically<br />

placed start/stop buttons, greater information gathering<br />

capabilities, and optional static discharge protection.<br />

The technology works with transponders in accordance<br />

with ISO specifications, in widths from 10mm to 160mm<br />

(with lengths of 10mm to 180 mm). Pre-printed labels<br />

with widths from 20mm to 200mm can be applied<br />

at rates up to 50 meters/minute. An on board RFID<br />

reader ensures the readability of each RFID tag<br />

after integration. An automatic control system keeps<br />

transponders and printed labels in register.<br />

Labels&Labeling<br />

Anilox sleeves<br />

Simec<br />

Simec Group, active in the flexo industry for 40 years, has launched<br />

Sarlox Gold Sleeves – anilox sleeves, developed for high speed<br />

printing, with a new structure allowing for high stability and resistance.<br />

Sarlox Gold Extra Light – a version with 60 percent less weight – is also<br />

available. These rolls are already used in the label industry, are in a<br />

pre-launch phase for the flexible packaging industry, and are currently<br />

being tested for the corrugated sector.<br />

Simec has also introduced Profil Multi Purpose, a new version of its<br />

vertical cleaning system for anilox sleeves.<br />

Lector workflow management<br />

BST Pro Mark<br />

KEEP OUR READERS UPDATED<br />

Keep our readers updated by sending press<br />

releases about new products, news and<br />

appointments to jquirk@labels&labeling.com.<br />

Submissions will appear on our website, and may<br />

then be included in our online newsletter Label<br />

News and in Labels & Labeling.<br />

BST Pro Mark has launched Lector Work Flow Management – a<br />

software tool for managing print quality and throughput from printing<br />

to shipping across multiple machines. It is used in conjunction with the<br />

company’s Shark 100% inspection systems or Premius print process<br />

management systems, installed on presses or re-winders up to 80”<br />

web widths.<br />

Lector Work Flow Management is used to display and evaluate<br />

process job data and to help manage throughput from one machine<br />

to the next – for example, press to re-winder – and to generate reports<br />

for jobs that have been produced on machines with BST Shark or<br />

Premius systems as the inspection/print quality assurance system. It is<br />

installed and operated on a personal computer, which is linked to the<br />

inspection/quality assurance systems in the process, and accesses the<br />

job data via a network.<br />

Lector Work Flow Management provides access to all events and<br />

information collected by the inspection/quality assurance system, from<br />

basic job information to detailed defect information and images. This