Wishesh December Magazine 2015

Wishesh December Magazine has more excited stories of Diwali Festival of Lights, Karatar Singh Sarabha was an Indian Sikh revolutionary, Indra Nooyi Chairman of PepsiCo, Infocus of Make in India, Mark Zukerberg India Visit, Healthly Romantic Tips and many more on this month magazine.

Wishesh December Magazine has more excited stories of Diwali Festival of Lights, Karatar Singh Sarabha was an Indian Sikh revolutionary, Indra Nooyi Chairman of PepsiCo, Infocus of Make in India, Mark Zukerberg India Visit, Healthly Romantic Tips and many more on this month magazine.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

quality.<br />

The colours are applied as<br />

per the specifications of the<br />

designers and also as per the<br />

customers order.<br />

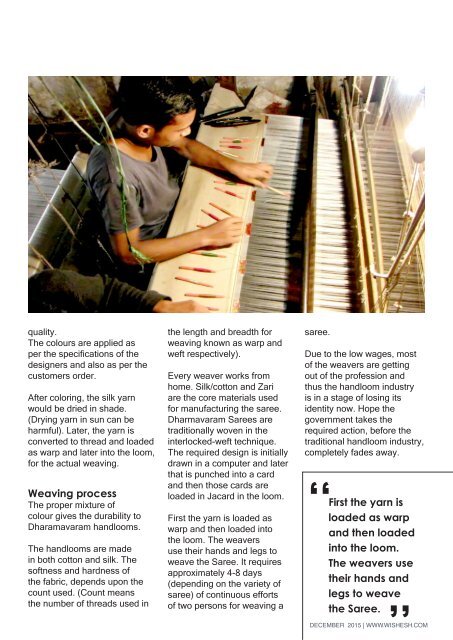

After coloring, the silk yarn<br />

would be dried in shade.<br />

(Drying yarn in sun can be<br />

harmful). Later, the yarn is<br />

converted to thread and loaded<br />

as warp and later into the loom,<br />

for the actual weaving.<br />

Weaving process<br />

The proper mixture of<br />

colour gives the durability to<br />

Dharamavaram handlooms.<br />

The handlooms are made<br />

in both cotton and silk. The<br />

softness and hardness of<br />

the fabric, depends upon the<br />

count used. (Count means<br />

the number of threads used in<br />

the length and breadth for<br />

weaving known as warp and<br />

weft respectively).<br />

Every weaver works from<br />

home. Silk/cotton and Zari<br />

are the core materials used<br />

for manufacturing the saree.<br />

Dharmavaram Sarees are<br />

traditionally woven in the<br />

interlocked-weft technique.<br />

The required design is initially<br />

drawn in a computer and later<br />

that is punched into a card<br />

and then those cards are<br />

loaded in Jacard in the loom.<br />

First the yarn is loaded as<br />

warp and then loaded into<br />

the loom. The weavers<br />

use their hands and legs to<br />

weave the Saree. It requires<br />

approximately 4-8 days<br />

(depending on the variety of<br />

saree) of continuous efforts<br />

of two persons for weaving a<br />

saree.<br />

Due to the low wages, most<br />

of the weavers are getting<br />

out of the profession and<br />

thus the handloom industry<br />

is in a stage of losing its<br />

identity now. Hope the<br />

government takes the<br />

required action, before the<br />

traditional handloom industry,<br />

completely fades away.<br />

‘‘<br />

First the yarn is<br />

loaded as warp<br />

and then loaded<br />

into the loom.<br />

The weavers use<br />

their hands and<br />

legs to weave<br />

the Saree.<br />

‘‘<br />

DECEMBER <strong>2015</strong> | WWW.WISHESH.COM