Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

issue #1 ©<br />

l i n k e d<br />

39<br />

4<br />

j a n o s c h k a p a c k a g i n g : c o n v e r t e r s<br />

expansion of the range of flexographic<br />

products and services<br />

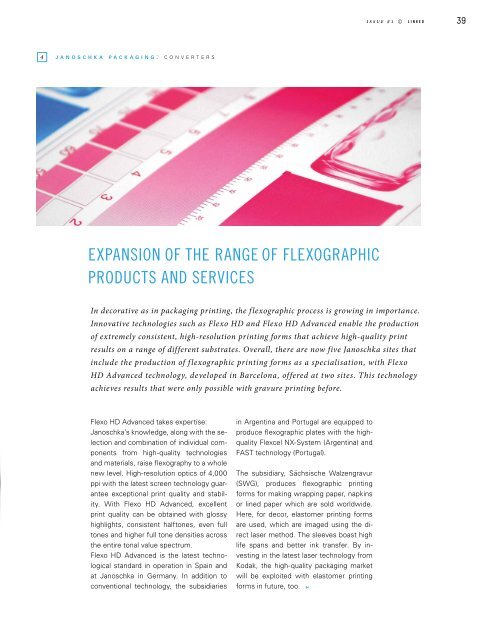

In decorative as in packaging printing, the flexographic process is growing in importance.<br />

Innovative technologies such as Flexo HD and Flexo HD Advanced enable the production<br />

of extremely consistent, high-resolution printing forms that achieve high-quality print<br />

results on a range of different substrates. Overall, there are now five <strong>Janoschka</strong> sites that<br />

include the production of flexographic printing forms as a specialisation, with Flexo<br />

HD Advanced technology, developed in Barcelona, offered at two sites. This technology<br />

achieves results that were only possible with gravure printing before.<br />

Flexo HD Advanced takes expertise:<br />

<strong>Janoschka</strong>’s knowledge, along with the selection<br />

and combination of individual components<br />

from high-quality technologies<br />

and materials, raise flexography to a whole<br />

new level. High-resolution optics of 4,000<br />

ppi with the latest screen technology guarantee<br />

exceptional print quality and stability.<br />

With Flexo HD Advanced, excellent<br />

print quality can be obtained with glossy<br />

highlights, consistent halftones, even full<br />

tones and higher full tone densities across<br />

the entire tonal value spectrum.<br />

Flexo HD Advanced is the latest technological<br />

standard in operation in Spain and<br />

at <strong>Janoschka</strong> in Germany. In addition to<br />

conventional technology, the subsidiaries<br />

in Argentina and Portugal are equipped to<br />

produce flexographic plates with the highquality<br />

Flexcel NX-System (Argentina) and<br />

FAST technology (Portugal).<br />

The subsidiary, Sächsische Walzengravur<br />

(SWG), produces flexographic printing<br />

forms for making wrapping paper, napkins<br />

or lined paper which are sold worldwide.<br />

Here, for decor, elastomer printing forms<br />

are used, which are imaged using the direct<br />

laser method. The sleeves boast high<br />

life spans and better ink transfer. By investing<br />

in the latest laser technology from<br />

Kodak, the high-quality packaging market<br />

will be exploited with elastomer printing<br />

forms in future, too.