Catalogue Measurement Technology ProGrit

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

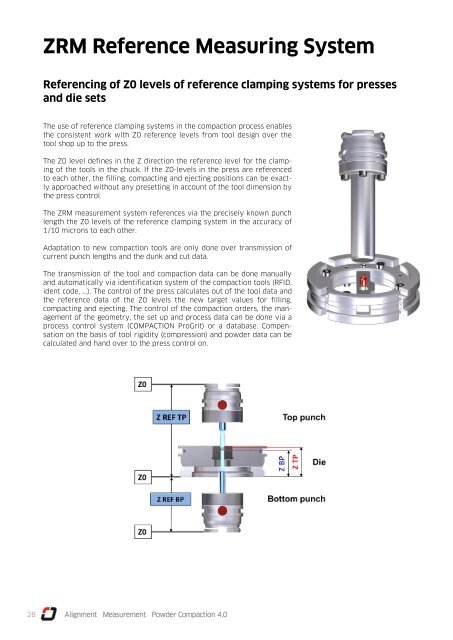

ZRM Reference Measuring System<br />

Referencing of Z0 levels of reference clamping systems for presses<br />

and die sets<br />

The use of reference clamping systems in the compaction process enables<br />

the consistent work with Z0 reference levels from tool design over the<br />

tool shop up to the press.<br />

The Z0 level defines in the Z direction the reference level for the clamping<br />

of the tools in the chuck. If the Z0-levels in the press are referenced<br />

to each other, the filling, compacting and ejecting positions can be exactly<br />

approached without any presetting in account of the tool dimension by<br />

the press control.<br />

The ZRM measurement system references via the precisely known punch<br />

length the Z0 levels of the reference clamping system in the accuracy of<br />

1/10 microns to each other.<br />

Adaptation to new compaction tools are only done over transmission of<br />

current punch lengths and the dunk and cut data.<br />

The transmission of the tool and compaction data can be done manually<br />

and automatically via identification system of the compaction tools (RFID,<br />

ident code, ...). The control of the press calculates out of the tool data and<br />

the reference data of the Z0 levels the new target values for filling,<br />

compacting and ejecting. The control of the compaction orders, the management<br />

of the geometry, the set up and process data can be done via a<br />

process control system (COMPACTION <strong>ProGrit</strong>) or a database. Compensation<br />

on the basis of tool rigidity (compression) and powder data can be<br />

calculated and hand over to the press control on.<br />

28 Alignment <strong>Measurement</strong> Powder Compaction 4.0