Catalogue Measurement Technology ProGrit

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PAS-3i Palletization Alignment System<br />

Palletizing and positioning of compaction tools - punch and die<br />

The PAS-3i system is used for the high precision alignment of punches and dies on pallets of reference clamping<br />

systems.<br />

Modern production concepts manufacture punches and dies directly on pallets of reference clamping systems.<br />

Often it is necessary to align punches and dies on pallets. This is the case when existing unpalletized tools<br />

(existing tools) should be placed first time on pallets, or when newly produced tools have to be corrected<br />

regarding the position to the pallet. Another important application arises from the necessary positioning of wire<br />

cutted punches, which cannot be manufactured on pallets in the wire cut process.<br />

The PAS-3i system moves according to the position deviations X, Y and C the compaction tool to the target<br />

position (X=Y=C=0). The position deviations are measured in relation to the reference clamping system on a<br />

coordinate measurement machine. Deviations in the die position in relation to the reference clamping system<br />

will be calculated in the target position of the punch.<br />

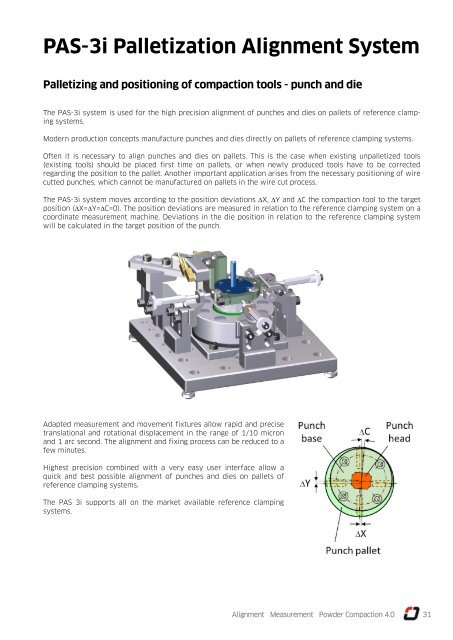

Adapted measurement and movement fixtures allow rapid and precise<br />

translational and rotational displacement in the range of 1/10 micron<br />

and 1 arc second. The alignment and fixing process can be reduced to a<br />

few minutes.<br />

Highest precision combined with a very easy user interface allow a<br />

quick and best possible alignment of punches and dies on pallets of<br />

reference clamping systems.<br />

The PAS 3i supports all on the market available reference clamping<br />

systems.<br />

Alignment <strong>Measurement</strong> Powder Compaction 4.0 31