Catalogue Measurement Technology ProGrit

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

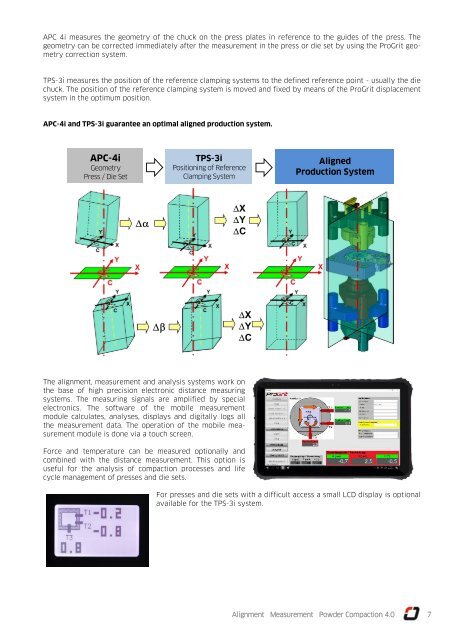

APC 4i measures the geometry of the chuck on the press plates in reference to the guides of the press. The<br />

geometry can be corrected immediately after the measurement in the press or die set by using the <strong>ProGrit</strong> geometry<br />

correction system.<br />

TPS-3i measures the position of the reference clamping systems to the defined reference point - usually the die<br />

chuck. The position of the reference clamping system is moved and fixed by means of the <strong>ProGrit</strong> displacement<br />

system in the optimum position.<br />

APC-4i and TPS-3i guarantee an optimal aligned production system.<br />

APC-4i<br />

Geometry<br />

Press / Die Set<br />

TPS-3i<br />

Positioning of Reference<br />

Clamping System<br />

Aligned<br />

Production System<br />

The alignment, measurement and analysis systems work on<br />

the base of high precision electronic distance measuring<br />

systems. The measuring signals are amplified by special<br />

electronics. The software of the mobile measurement<br />

module calculates, analyses, displays and digitally logs all<br />

the measurement data. The operation of the mobile measurement<br />

module is done via a touch screen.<br />

Force and temperature can be measured optionally and<br />

combined with the distance measurement. This option is<br />

useful for the analysis of compaction processes and life<br />

cycle management of presses and die sets.<br />

For presses and die sets with a difficult access a small LCD display is optional<br />

available for the TPS-3i system.<br />

Alignment <strong>Measurement</strong> Powder Compaction 4.0 7