Catalogue Measurement Technology ProGrit

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

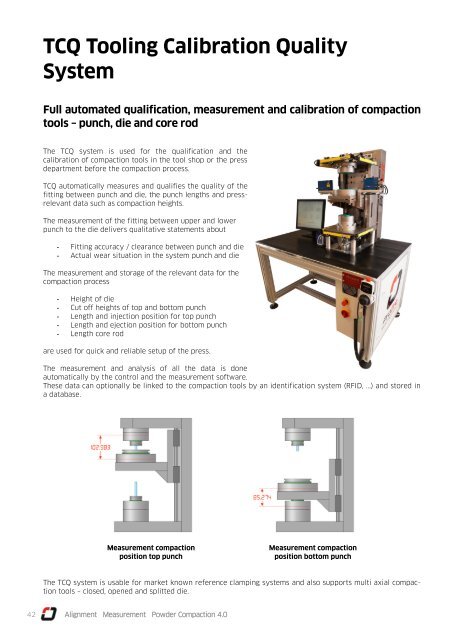

TCQ Tooling Calibration Quality<br />

System<br />

Full automated qualification, measurement and calibration of compaction<br />

tools – punch, die and core rod<br />

The TCQ system is used for the qualification and the<br />

calibration of compaction tools in the tool shop or the press<br />

department before the compaction process.<br />

TCQ automatically measures and qualifies the quality of the<br />

fitting between punch and die, the punch lengths and pressrelevant<br />

data such as compaction heights.<br />

The measurement of the fitting between upper and lower<br />

punch to the die delivers qualitative statements about<br />

- Fitting accuracy / clearance between punch and die<br />

- Actual wear situation in the system punch and die<br />

The measurement and storage of the relevant data for the<br />

compaction process<br />

- Height of die<br />

- Cut off heights of top and bottom punch<br />

- Length and injection position for top punch<br />

- Length and ejection position for bottom punch<br />

- Length core rod<br />

are used for quick and reliable setup of the press.<br />

The measurement and analysis of all the data is done<br />

automatically by the control and the measurement software.<br />

These data can optionally be linked to the compaction tools by an identification system (RFID, ...) and stored in<br />

a database.<br />

<strong>Measurement</strong> compaction<br />

position top punch<br />

<strong>Measurement</strong> compaction<br />

position bottom punch<br />

The TCQ system is usable for market known reference clamping systems and also supports multi axial compaction<br />

tools – closed, opened and splitted die.<br />

42 Alignment <strong>Measurement</strong> Powder Compaction 4.0