2017 May June Marina World

The magazine for the marina industry

The magazine for the marina industry

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Marina</strong><br />

www.marinaworld.com<br />

<strong>World</strong><br />

<strong>May</strong>/<strong>June</strong> <strong>2017</strong><br />

Issue 101<br />

Essential reading for marina and waterfront developers, planners and operators

SF <strong>Marina</strong> has been building and<br />

installing floating breakwaters and pontoons for<br />

marinas worldwide since 1918. We are committed<br />

to finding the best solution for every site.<br />

The sturdy tugboat pontoons for the operation of<br />

large vessels in a port on the Swedish West Coast are<br />

examples of the capacity of our factory in<br />

Wallhamn. The pontoons are 10 meters wide and<br />

23 m long. They are also designed to accommodate<br />

heavy construction vehicles.<br />

Photo: Stig Jansson, SF Pontona<br />

Postal address: SF <strong>Marina</strong> System AB, Propellergangen 4, 417 64 Goteborg, Sweden<br />

Telephone: + 46 31 779 07 65 e-mail: info@sfmarina.com web: www.sfmarina.com

<strong>Marina</strong><br />

<strong>World</strong><br />

<strong>May</strong>/<strong>June</strong> <strong>2017</strong> Vol. 17, No. 5<br />

19<br />

CONTENTS<br />

<strong>World</strong> News 7<br />

Cover Story 12<br />

Sarah Devlin talks to Chuck and Ann Lagasse<br />

about redeveloping marinas in Massachusetts<br />

40<br />

<strong>Marina</strong> Planning & Design 19<br />

Ana <strong>Marina</strong> (Vietnam); <strong>Marina</strong> d’Arechi<br />

(Italy); Motuoapa <strong>Marina</strong> (New Zealand); St<br />

Katharine Docks (UK); Roermond City <strong>Marina</strong><br />

(Netherlands)<br />

51<br />

Pontoons/Docks & Decking 40<br />

Launching and installing the latest products for<br />

marina docks and decks<br />

Boatlifts 51<br />

Products & Services 55<br />

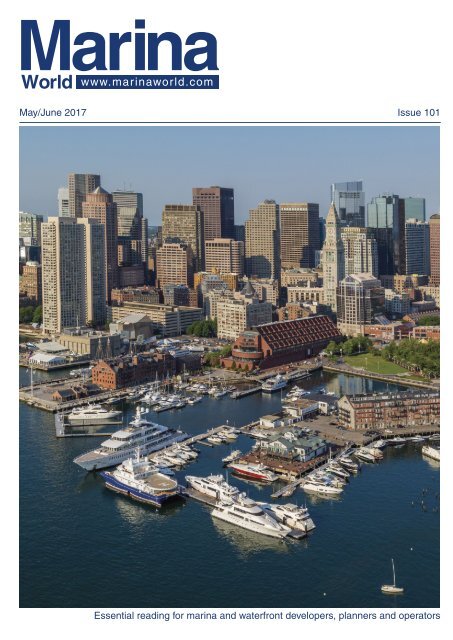

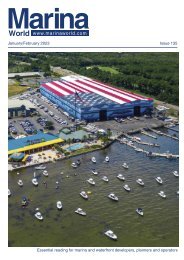

On the cover: Once a Boston<br />

Harbor marina in a state of disrepair<br />

and neglect, Boston Yacht Haven<br />

was rebuilt from scratch under<br />

the ownership of Chuck and Ann<br />

Lagasse. Pier 8 (now Charlestown<br />

<strong>Marina</strong>) was next in line for<br />

redevelopment, and Provincetown<br />

<strong>Marina</strong> nears completion. Read<br />

more on p.12<br />

Cover photo: Jim Raycroft<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 3

WE DESIGN AND BUILD<br />

MARINAS THAT MEET UNIQUE<br />

REQUIREMENTS<br />

Harborage <strong>Marina</strong>, St. Petersburg, Fl<br />

WWW.MARINETEK.NET

<strong>Marina</strong><br />

<strong>World</strong><br />

HEAD OFFICE MAILING ADDRESS &<br />

SUBSCRIPTION ENQUIRIES<br />

Loud & Clear Publishing Ltd,<br />

School Farm, School Road, Terrington St. John,<br />

Cambridgeshire PE14 7SJ, UK<br />

Editor<br />

Carol Fulford<br />

T: +44 (0) 1945 881018 F: +44 (0) 1621 855 867<br />

E: carolfulford@marinaworld.co.uk<br />

Special Correspondent<br />

Charlotte Niemiec<br />

E:charlotte@marinaworld.co.uk<br />

Advertisement/Commercial Director<br />

Julia Hallam<br />

T: +44 (0) 1621855 890 F: +44 (0) 1621 855867<br />

E: juliahallam@marinaworld.co.uk<br />

Administration Manager<br />

Corinna Francis T: +44 (0) 1621855 890<br />

E: corinnafrancis@marinaworld.co.uk<br />

Accounts Manager<br />

Magdalena Charman T: +44 (0) 1403 733678<br />

E: accounts@marinaworld.co.uk<br />

Advertisement Production<br />

Nick Hing T: +44 (0) 1323 490384<br />

E: adstudio@marinaworld.co.uk<br />

NORTH AMERICAN OFFICE<br />

Sales Director Americas<br />

Philippe Critot<br />

PO Box 29759, Los Angeles, CA 90029-0759, USA<br />

T: +1 323 660 5459 F: +1 323 660 6030<br />

E: pcritot@marinaworld.com<br />

FRENCH OFFICE<br />

Publisher’s Representative<br />

Catherine Métais T: +33 6 60 17 75 81<br />

E: c.metais@parisrai.com<br />

ITALIAN OFFICE<br />

Advertisement Representative<br />

Ediconsult Internazionale srl<br />

piazza Fontane Marose 3, 16123 Genoa, Italy<br />

T: +39 010 583 684 F: +39 010 566 578<br />

E: genova@ediconsult.com<br />

CHINESE OFFICE<br />

Publisher’s Representative<br />

Simon Ding<br />

Bridge International Holding, Rm. 401, Building<br />

A, No. 55 Jinyu Road, Minhang District. 201103<br />

Shanghai, China<br />

T: +86 21 33231328 F: +86 21 33231366<br />

E: simon@chcbiz.com<br />

<strong>Marina</strong> <strong>World</strong> (ISSN 1471-5856) is published<br />

bi-monthly by Loud & Clear Publishing Ltd,<br />

School Farm, School Road, Terrington St.<br />

John, Cambridgeshire PE14 7SJ, United Kingdom.<br />

The <strong>2017</strong> US annual subscription price is $160.<br />

Airfreight and mailing in the USA by agent named Air<br />

Business Ltd, c/o <strong>World</strong>net Shipping Inc., 156-15 146 th<br />

Avenue, 2 nd Floor, Jamaica, NY 11434, USA.<br />

Periodicals postage paid in Jamaica NY 11431.<br />

US Postmaster: Please send address changes to<br />

MARINA WORLD, c/o <strong>World</strong>net Shipping, Inc., 156-15,<br />

146 th Avenue, 2 nd Floor, Jamaica, NY 11434, USA.<br />

Subscription records are maintained at Loud & Clear<br />

Publishing Ltd, School Farm, School Road, Terrington<br />

St. John, Cambridgeshire PE14 7SJ, United Kingdom.<br />

Air Business Ltd acts as Loud & Clear Publishing’s<br />

mailing agent.<br />

<strong>Marina</strong> <strong>World</strong> is available on subscription at the following<br />

cost:<br />

1 year (6 issues) - £80.00 Sterling ($160)<br />

2 years (12 issues) - £140.00 Sterling ($280)<br />

No part of this publication may be reproduced without<br />

the prior permission of Loud & Clear Publishing Ltd, the<br />

copyright owners. Upon application, permission may be<br />

freely granted to copy abstracts of articles on condition<br />

that a full reference to the source is given.<br />

Printed in the UK by Stephens & George<br />

© <strong>2017</strong> Loud & Clear Publishing Ltd<br />

Views expressed by individual contributors in this issue<br />

are not necessarily those of Loud & Clear Publishing<br />

Ltd. Equally, the inclusion of advertisements in this<br />

magazine does not constitute endorsement of the<br />

companies, products and services concerned by Loud &<br />

Clear Publishing Ltd. The publisher reserves the right to<br />

refuse advertising.<br />

Ancient<br />

footsteps<br />

Carol Fulford<br />

Editor<br />

FROM THE EDITOR<br />

If the hottest news in our March/April issue was the Safe Harbor <strong>Marina</strong>s<br />

acquisition of Brewer Yacht Yards, the hot spot for <strong>May</strong>/<strong>June</strong> goes to Suntex<br />

<strong>Marina</strong> Investors and its purchase of the eleven Loggerhead <strong>Marina</strong> sites (see<br />

p. 7). Together, the two US entities now own in excess of 100 American marinas<br />

and I imagine the quest to expand these portfolios is far from over.<br />

Suntex, which also slipped in the purchase of The Ridges <strong>Marina</strong> on Lake Chatuge<br />

in North Georgia in March, has committed to maintaining a philanthropic partnership<br />

with Loggerhead Marinelife Center as part of the buy-out agreement. Both Suntex<br />

and Loggerhead claim that preserving the environment is one of their core values,<br />

and support for the Marinelife Center in Juno Beach, Florida will reinforce the Suntex<br />

role of environmental stewardship. The centre focuses on the conservation of ocean<br />

life with special emphasis on threatened and endangered sea turtles.<br />

Our industry’s effort to preserve and protect the environment is a theme that runs<br />

through every issue of <strong>Marina</strong> <strong>World</strong>. In <strong>May</strong>/<strong>June</strong>, we read that work halted during<br />

the build of Motuoapa <strong>Marina</strong> on Lake Taupo in the North Island of New Zealand<br />

for the nesting season of black-billed gulls and that the entire project, which had a<br />

zero cut to fill balance for dredged material, resulted in pristine water and improved<br />

habitat for trout.<br />

In the heart of a big city, the fate of birds and fish isn’t uppermost in most people’s<br />

minds. But at St Katharine Docks in London, the ecosystem was taken very<br />

seriously. Care was taken not to disrupt flora and fauna around the docks including<br />

fish, ducks and other birds during the recent refurbishment. Fish spawning brushes<br />

were also installed to encourage more fish species within the marina.<br />

But when it comes to newbuild or refurbishment, planners are not always<br />

confronted with the need to preserve living species as I read in a recent ABC<br />

Kimberley news report posted by Ben Collins. Collins reports that National Heritagelisted<br />

dinosaur footprints could disrupt plans to build a new marina in Broome,<br />

Western Australia. The sauropod footprints on the proposed marina site are part of<br />

important track sites, some of which were described in the report by University of<br />

Queensland palaeontologist Dr Steve Salisbury as being ‘quite rare and scientifically<br />

significant’.<br />

Sauropods had whiplash tails, stocky limbs and long necks, and were the biggest<br />

vertebrates ever to walk the earth. They travelled in herds munching foliage and<br />

the Broome brontosaurs were blissfully ignorant of the fact that in around 65 million<br />

years’ time the impact of their footfalls would cause marina planning problems.<br />

As Rob Vrancken CMM says (p. 36), when it comes to building marinas - “nothing<br />

ever goes according to plan.”<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 5

Next Generation <strong>Marina</strong>s<br />

THE WORLD’S MOST<br />

COMPREHENSIVE MARINA BUILDER<br />

bellingham-marine.com

WORLD NEWS<br />

Bahrain plan unveiled<br />

BAHRAIN: Bahrain <strong>Marina</strong> Development Company unveiled the master plan<br />

of the ambitious Bahrain <strong>Marina</strong> for the first time at the Gulf Property Show in<br />

April.<br />

Scheduled to complete by 2020,<br />

Bahrain <strong>Marina</strong> will include a fivestar<br />

hotel, serviced hotel apartments,<br />

seafront hotel villas and a residential<br />

tower with freehold apartments. It<br />

will have a unique sea front with a<br />

yacht club, retail and dining areas<br />

surrounding a circular basin with berths<br />

for vessels of various sizes.<br />

The lead designer of the project is<br />

Benoy, an international architectural<br />

Loggerhead sells to Suntex<br />

USA: Loggerhead <strong>Marina</strong> has sold 11 of its marinas throughout Florida to<br />

Suntex <strong>Marina</strong> Investors LLC. Loggerhead is one of the best-known and wellrespected<br />

marina operating brands in the US southeast with premier locations<br />

on the east and Gulf coasts of Florida.<br />

The transaction included over<br />

2,300 wet and dry slips and multiple<br />

restaurants located in luxury locations<br />

stretching from Miami to Daytona<br />

Beach, and on Florida’s west coast.<br />

As Loggerhead is a well-established<br />

brand in the marketplace, the name will<br />

be retained at all the facilities while the<br />

transition takes place.<br />

“We are excited to be part of a<br />

brand that shares our core values of<br />

providing the highest quality family<br />

experience, as well as protecting our<br />

environment for the enjoyment of<br />

current and future generations. I will<br />

remain fully engaged in the marine<br />

industry, in both seeing through<br />

the workplace transition of all our<br />

Loggerhead team members, and in<br />

expanding relationships through my<br />

involvement with the Loggerhead<br />

Marinelife Center,” said Raymond<br />

Graziotto, president and CEO of Seven<br />

Kings Holdings, Inc., and founder of<br />

Loggerhead <strong>Marina</strong>.<br />

“This transaction will be<br />

transformational for Suntex and our<br />

efforts to continue to provide an<br />

unmatched customer experience<br />

around the country. The Loggerhead<br />

marinas greatly expand our ability to<br />

offer our Suntex customers access to<br />

prime marina locations and amenities<br />

throughout the state of Florida,” said<br />

Bryan Redmond, founding principal of<br />

Suntex.<br />

firm with vast experience in working<br />

alongside large scale projects in the<br />

region. Bahrain <strong>Marina</strong> Development<br />

Company earlier announced the<br />

appointment of Al Hassanain<br />

Contracting Company to implement<br />

the first phase of the project, which<br />

includes all the enabling and marinerelated<br />

works, earthworks, shore<br />

protection, quay walls, culvert crossings<br />

and shore development.<br />

“Not only are the Loggerhead<br />

properties the perfect complement<br />

to our existing marina portfolio, but<br />

they share our deep and driving<br />

commitment to the environment, and to<br />

clean and responsible boating. Every<br />

Loggerhead property participates in the<br />

Responsible Boating Initiative, and we<br />

will apply those same practices to all<br />

of our Suntex locations,” added Suntex<br />

principal Mitchell E. Jones.<br />

As part of the purchase, Suntex has<br />

committed to maintain a philanthropic<br />

partnership with the Loggerhead<br />

Marinelife Center. A non-profit facility<br />

focused on ocean and sea turtle<br />

conservation, the facility houses live<br />

sea turtles and other coastal creatures.<br />

It also provides outreach programmes<br />

and educational experiences for<br />

children, and hosts more than 300,000<br />

guests per year.<br />

Michael Nissley and Jason Spalding<br />

of CBRE’s <strong>Marina</strong> Services represented<br />

Seven Kings Holdings/Loggerhead<br />

<strong>Marina</strong> in the portfolio transaction.<br />

The opportunity was marketed<br />

internationally and received a<br />

substantial amount of interest from<br />

marina owners, operators, private<br />

equity firms and property developers.<br />

The marina portfolio sale illustrates<br />

the current trend in the USA towards<br />

consolidation.<br />

Suntex now has a portfolio of 43<br />

marinas.<br />

EXPERIENCE<br />

INTEGRITY<br />

PASSION<br />

VISION<br />

LEADERSHIP<br />

THE WOR<br />

COMPREH<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong><br />

7

The most important marina<br />

construction decision lays<br />

beneath the surface<br />

SEAFLEX CAN HANDLE PRACTICALLY ANY TIDE, ANY WAVE, ANY DEPTH, ANY BOTTOM TYPE & HURRICANE STRENGTH FORCES.<br />

Make a mooring decision worthy of<br />

your entire marina investment<br />

You spend a lot of time researching options for your marina build or upgrade. Since the<br />

anchoring is what is going to hold your marina investment in place it is arguably the<br />

most crucial components you will decide on. Seaflex is an elastic mooring solution that<br />

expands and retracts with each tide and wave, taking on and dampening the forces<br />

year after year. It does this while being invisible from the surface, creating some<br />

of the most modern, sleek, state of the art marinas of the world.<br />

With 45 years of research and development Seaflex is the<br />

most technologically advanced mooring option in the<br />

world, anchoring thousands of marinas, wave<br />

attenuators and buoys worldwide.<br />

Research your options, give<br />

your marina the mooring<br />

solution it deserves!<br />

www.seaflex.net<br />

SINCE 1970 | INTERNATIONAL +46 90 160650 | US & CANADA +1 (310) 548 9100 | MW@SEAFLEX.NET

WORLD NEWS<br />

Merger pays<br />

dividends<br />

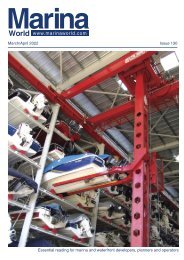

USA: Since Sullivan Flotation<br />

Systems and Atlantic Meeco<br />

merged almost two years ago, the<br />

new Meeco Sullivan business has<br />

revamped management and sales<br />

teams, streamlined production<br />

processes, and invested in new<br />

equipment and highly skilled<br />

employees.<br />

National sales manager, Ralph Morley,<br />

says “our shared vision and purpose,<br />

coupled with the major investments<br />

we’ve made in our production facilities,<br />

are really paying off.”<br />

Growth plans have included adding<br />

significant line workers and longer shifts<br />

at the Warwick facility and extending<br />

capability in McAlester, Oklahoma, by<br />

adding eight new welding machines<br />

and a new plasma cutter; doubling the<br />

capacity of its frame line; and adding<br />

an additional assembly line and an<br />

additional accessories line. The current<br />

production schedule comprises six day<br />

weeks with four 12 hour shifts and two<br />

eight hour shifts.<br />

2016 was an excellent year for the<br />

company as it won over 200 new<br />

contracts, including the largest marina<br />

contract ever awarded by the New York<br />

State Park System for a 13-dock, 1,063-<br />

slip floating system at Lake Erie <strong>Marina</strong>.<br />

James Watt<br />

appoints new operator<br />

UK: The James Watt Dock LLP, a partnership between Peel Holdings and<br />

Riverside Inverclyde, has handed over the operation of James Watt Dock<br />

<strong>Marina</strong> (above) to <strong>Marina</strong> Projects.<br />

<strong>Marina</strong> Projects has been granted a<br />

long lease and has committed to invest<br />

in the expansion of marina facilities<br />

including 40 berths planned for later<br />

in <strong>2017</strong>. The existing operational staff<br />

will remain as their experience and<br />

knowledge of the marina customers is<br />

crucial to the success of the marina.<br />

Geoff Phillips, executive chairman<br />

of <strong>Marina</strong> Projects Ltd, said: “I am<br />

delighted that <strong>Marina</strong> Projects has been<br />

selected as the operator for James Watt<br />

Dock <strong>Marina</strong>. The <strong>Marina</strong> Projects team<br />

has a great deal of experience in the<br />

marina sector including the operation in<br />

Whitehaven <strong>Marina</strong> in Cumbria. We look<br />

forward to working with the existing staff<br />

in developing James Watt Dock <strong>Marina</strong>.”<br />

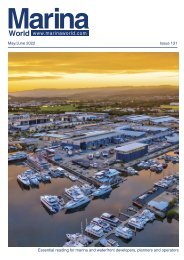

Gladstone earns four Gold Anchors<br />

AUSTRALIA: Gladstone <strong>Marina</strong> in Queensland was awarded 4 Gold Anchors under the Global Gold Anchor accreditation<br />

scheme at a presentation attended by <strong>Marina</strong> Industries Association (MIA) and Gladstone Port Corporation (GPC)<br />

representatives. Gladstone <strong>Marina</strong> has 320 berths and mooring boat spaces, and modern facilities to suit local and<br />

visiting boaters.<br />

MIA director, John Spragg CMP,<br />

presented the Global Gold Anchor<br />

certificate and flag to GPC’s CEO<br />

Peter O’Sullivan. “The marina and its<br />

surrounds are a great asset for the<br />

Gladstone community,” Spragg said.<br />

“The Gold Anchor assessor highlighted<br />

the very positive comments made by<br />

berth holders relating to the marina<br />

and its staff. The setting of the marina<br />

in a safe harbour and within extensive<br />

parklands is a credit to GPC.”<br />

Peter O’Sullivan commented: “GPC<br />

is committed to continually improving<br />

the facilities and services at Gladstone<br />

<strong>Marina</strong> to meet the needs of its users<br />

and our community.”<br />

“In 2014 we received a 3.5 Gold<br />

Anchor rating, which made us the first<br />

marina in Queensland to receive such<br />

accreditation,” he added. “Since then,<br />

it has been a focus and commitment of<br />

our Gladstone <strong>Marina</strong> staff and Parks<br />

and Gardens teams to increase this<br />

rating, which we have now achieved.”<br />

John Spragg (fourth from left) presents the<br />

certificate to Peter O’Sullivan.<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 9

Specialists in Utility Services for<br />

<strong>Marina</strong>s & Waterfront Locations<br />

MARINA SERVICE PEDESTALS<br />

MARINA LIGHTING SOLUTIONS<br />

The Leader in<br />

<strong>Marina</strong> Services &<br />

EV Charging<br />

EMERGENCY SERVICES<br />

ELECTRIC VEHICLE CHARGING<br />

Head office contact:<br />

t: ++44 (0) 1205 724754<br />

f: ++44 (0) 1205 724876<br />

rolec@rolecserv.co.uk<br />

Rolec Services Ltd<br />

Ralphs Lane, Frampton West<br />

Boston, Lincolnshire<br />

UK. PE20 1QU<br />

www.rolecserv.com

Paphos<br />

project stalls<br />

CYPRUS: According to reports in<br />

Cyprus Mail, the Paphos Chamber<br />

of Commerce & Industry (PCCI)<br />

has withdrawn its approval of the<br />

Poseidon consortium bid to develop<br />

Paphos <strong>Marina</strong>.<br />

PCCI president Andreas Demetriades<br />

told the newspaper that “on the basis<br />

of the financial statements [Poseidon]<br />

submitted, it was concluded that the<br />

terms and conditions of the competition<br />

were not being met.”<br />

It is understood that runner-up<br />

development company Pafilia has been<br />

called to submit paperwork to take over.<br />

The Poseidon consortium says the<br />

decision to reject the bid was “unlawful”.<br />

Poseidon intends to launch an appeal<br />

with the Supreme Court.<br />

30 years<br />

of marina<br />

cooperation<br />

EUROPE: TransEurope <strong>Marina</strong>s,<br />

formerly Transmanche, is celebrating<br />

three decades of association. The<br />

group now has 73 member marinas<br />

and its unchanged maxims hinge on<br />

working in cooperation and offering<br />

a discount system to encourage<br />

berth holders to sail around the<br />

network.<br />

Julian Goldie (far right), owner of<br />

Tollesbury <strong>Marina</strong>, has travelled the<br />

world in the interest of promoting<br />

industry links and also dedicated time<br />

as an early TransEurope chairman.<br />

He expressed his pleasure at seeing<br />

the network’s successful expansion:<br />

“Tollesbury <strong>Marina</strong> has been an<br />

enthusiastic member and supporter<br />

of TransEurope <strong>Marina</strong>s since our<br />

joining in 1999,” he said. “We always<br />

really enjoy meeting up with other<br />

TransEurope members and exchanging<br />

experiences, as well as new best<br />

practices. The additional benefit of<br />

membership is also much appreciated<br />

Careful planning for<br />

MYH expansion<br />

UK: Mylor Yacht Harbour (MYH) near Falmouth, Cornwall, has begun a<br />

widespread consultation into a small and sensitive extension (outlined<br />

above) to its existing marina.<br />

Both formal and informal<br />

consultation processes are being<br />

held well in advance of MYH<br />

submitting a full planning application<br />

for a scheme that could provide<br />

berths for 30 extra boats. This will<br />

meet customer demand whilst<br />

supporting the future sustainability<br />

of the harbour, the related services<br />

and the associated employment it<br />

provides.<br />

The historic harbour is a thriving<br />

by our berth<br />

holders,<br />

who are<br />

encouraged<br />

to get out<br />

sailing from<br />

port to port. It<br />

is thrilling to<br />

have watched the membership grow to<br />

include over 70 marinas, now located<br />

all over Europe.”<br />

Current chairman, Jean-Michel<br />

Gaigné (above left), manager of<br />

Saint-Quay Port D’Armor in France<br />

shared his satisfaction in reaching<br />

this milestone: “One of TransEurope<br />

<strong>Marina</strong>s’ greatest strengths has<br />

been the group’s faith in cooperative<br />

activity; almost counter-intuitively<br />

helping to promote other marinas and<br />

encouraging our berth holders to set<br />

their sails for distant shores! Now,<br />

WORLD NEWS<br />

marine centre with high demand for<br />

services. Managing director, Neil<br />

Salter, stresses that the £1 million+<br />

expansion will not have negative side<br />

effects on its appeal.<br />

“The extension we’re proposing<br />

is fairly modest,” he says, “and we<br />

anticipate that it would enhance the<br />

site whilst not changing the views, the<br />

ambience or making any significant<br />

demands on either the environment or<br />

the shore-side infrastructure.”<br />

when reports about sector decline are<br />

bolstering everyone to find innovative<br />

solutions to buoy boating practice, I am<br />

especially proud of our members for<br />

being pioneers of the sharing economy<br />

within the marina industry.”<br />

Associated marinas are positioned<br />

at a minimum distance of a day’s sail<br />

in order to reduce competitive conflict<br />

and agree to maintain services at a<br />

level that inspires a ‘home from home’<br />

welcome.<br />

Further information:<br />

www.transeuropemarinas.com<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 11

COVER STORY<br />

Building big docks<br />

in a small town<br />

Provincetown <strong>Marina</strong> at the tip of Cape Cod in Massachusetts is being<br />

transformed into a megayacht destination with one of the largest breakwater<br />

systems on the East Coast. It’s the third marina in the area to receive a major<br />

overhaul, all at the hands of one industrious couple. Sarah Devlin reports<br />

Chuck and Ann Lagasse are not<br />

new to property development nor<br />

are they naïve when it comes to<br />

marina management. As former<br />

major landowners in Newburyport,<br />

Massachusetts, they are hands-on<br />

and intuitive about how they invest and<br />

improve properties.<br />

“We started by developing marinas<br />

and land for upland auxiliary uses,”<br />

Chuck says about Newburyport,<br />

where they developed and managed<br />

marinas and properties along the<br />

mouth of the Merrimack River 150 miles<br />

(241km) or approximately 60nm north<br />

of Provincetown. “When we started,<br />

we partnered with marinas that had<br />

something like 36 slips. In over 30<br />

years, we built over<br />

500 slips, in our own<br />

facilities and with<br />

partners.”<br />

“We’re about current<br />

uses and mixed use.<br />

[In Newburyport,] we<br />

had a great downtown<br />

with historic buildings,”<br />

Gigantic<br />

SF Type 600 breakwater<br />

units being delivered to<br />

the Provincetown site.<br />

Ann states. As part of that waterfront<br />

development, she and Chuck added<br />

restaurants and retail locations, totalling<br />

45 properties overall.<br />

“When we got involved, there were<br />

30 different owners and we worked to<br />

consolidate them. It was a big portfolio.<br />

It was our life.”<br />

She stops for a moment. “I think of us<br />

as redevelopers, not developers.”<br />

The road to Provincetown<br />

The timeline for the Lagasses and<br />

Provincetown <strong>Marina</strong> started in 2007.<br />

Chuck and Ann approached the Cabral<br />

family, the owners of Provincetown<br />

<strong>Marina</strong> (then called Fisherman’s<br />

Wharf), to discuss purchasing the<br />

Mason Sears, SF <strong>Marina</strong> Systems USA<br />

Provincetown <strong>Marina</strong> after refurbishment in 2016. The new<br />

elbow-shaped breakwater will run out from the left of<br />

the building towards the sailboat moorings.<br />

old commercial pier and marina with<br />

another financial partner. “We thought<br />

it needed some capital,” Chuck says<br />

diplomatically. The deal fell through for<br />

various reasons, not the least of which<br />

the recession that took hold of the<br />

market in 2008.<br />

That didn’t diminish their interest in<br />

the property, however. “Over the years<br />

I’ve followed it and we stayed in touch<br />

with the owners,” he states. “I always<br />

thought [Provincetown] was one of the<br />

premier boating destinations on the<br />

East Coast.”<br />

He’s referring to the protected<br />

harbour’s location, its deep basin,<br />

and the draw of area beaches and<br />

the historic town centre. Already<br />

a destination for ferry traffic out of<br />

Boston, Provincetown is 50 miles<br />

(80km) to the east, protected from the<br />

Atlantic by a spit of land. If Cape Cod<br />

were a human arm, curled into itself,<br />

Provincetown Harbor would be the<br />

inside of the arm’s fist. It’s a straight<br />

shot from Cape Cod Canal, which<br />

Anders Lindberg, SF <strong>Marina</strong><br />

12<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong>

COVER STORY<br />

bisects Cape Cod’s ‘arm’ and the ‘body’<br />

of Massachusetts. Those who travel<br />

through the Canal are cruising from<br />

Buzzard’s Bay and Vineyard Sound as<br />

well as such boating destinations as<br />

Martha’s Vineyard and Nantucket.<br />

“The town is wonderful,” Chuck<br />

states. “Great for biking, boating,<br />

outdoor activities and the most beautiful<br />

beaches. And, we don’t have a pleasure<br />

boat destination out here!”<br />

But he and Ann had other properties<br />

to attend to first, before landing in<br />

Provincetown.<br />

Late in the first decade of the 2000s,<br />

after the sale with the Cabral family fell<br />

through, a bank approached Chuck<br />

to gauge his interest in purchasing a<br />

bankrupt property in Boston Harbor.<br />

“We’re always looking for properties to<br />

rehabilitate,” he confirms.<br />

“We knew Boston was a great<br />

destination,” Ann adds. “There were<br />

no big boat facilities in the North End<br />

where the marina is located.”<br />

The facility now known as Boston<br />

Yacht Haven was in a state of disrepair<br />

and neglect, according to the Lagasses,<br />

and the docks needed to be completely<br />

replaced, but they were intrigued by a<br />

small inn on the property. (“First time<br />

we operated an inn!” Ann exclaims.)<br />

The Lagasses dismantled the marina<br />

and started from scratch.<br />

“We had a vision of building<br />

a breakwater that could handle<br />

megayachts,” Chuck says. They<br />

immediately started considering what<br />

kind of breakwater they might need for<br />

the area.<br />

In record time and inclement weather<br />

conditions, Chuck and Ann Lagasse<br />

spearheaded restoration of Charlestown<br />

<strong>Marina</strong> in 2014/15.<br />

“Boston Harbor was a<br />

considerable challenge<br />

because of the surge in<br />

there from commercial<br />

activity,” Chuck adds. In the<br />

end, they built a 1,000ft<br />

(305m) hybrid steel/concrete<br />

breakwater that circles the<br />

property. It acts not only<br />

as a breakwater, but also<br />

as a face pier to provide<br />

dockage for megayachts<br />

up to 400ft (122m). Smaller<br />

boats are located behind the<br />

breakwater, protected from<br />

the busy harbour’s surge.<br />

To get the facility into the<br />

marketplace quickly, they<br />

entered into an agreement<br />

with IGY <strong>Marina</strong>s in order<br />

to list the property as a destination<br />

location. In their first season, they<br />

saw four megayachts come in from<br />

the Mediterranean. They no longer<br />

have that relationship with IGY, but the<br />

megayachts continue to return.<br />

Next, they set their sights on Pier 8,<br />

aka Charlestown <strong>Marina</strong>, also located<br />

in Boston Harbor. The marina had been<br />

closed by the Attorney General’s office<br />

and the Department of Environmental<br />

Protection, because as Chuck says,<br />

“it was falling into the harbour.” They<br />

purchased the land in October 2014<br />

and were given 60 days to remove the<br />

old docks and any debris. As it turns<br />

out, that year Boston saw its snowiest<br />

season on record, with major snowfall<br />

starting in November and carrying<br />

through to March, totalling just over 9ft<br />

(3m).<br />

Chuck purchased a workboat from<br />

the infamous Deepwater Horizon<br />

BP oil spill in 2010, and hired local<br />

The original pier at Provincetown<br />

underwent refurbishment and<br />

accommodates vessels up to 125ft (38m).<br />

contractors Boston Bridge & Steel (out<br />

of East Boston) to build a 900ft (274m)<br />

concrete and steel breakwater. “People<br />

kept telling us ‘there’s no way you’ll be<br />

open in <strong>May</strong>’,” Chuck laughed. “I don’t<br />

think even our staff believed us.”<br />

But, despite the unprecedented<br />

snowfall, they had 250 slips ready for<br />

reservations for vessels ranging from<br />

small dinghies up to 400ft (122m)<br />

yachts by <strong>May</strong> 2015. “It came down to<br />

great community work,” Chuck says.<br />

Finally, Provincetown<br />

In February 2015, a little less than a<br />

year after opening Charlestown <strong>Marina</strong>,<br />

the Lagasses purchased Provincetown<br />

<strong>Marina</strong>. The existing 100ft (30m)<br />

pier had 50 slips up to 60ft (18m)<br />

surrounded by 100 moorings. They<br />

opened for business in <strong>June</strong> 2015 after<br />

focusing on such immediate needs as<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 13

Power to Trust.<br />

All All Eaton <strong>Marina</strong> Power & & Lighting power pedestals and and distribution<br />

equipment are are UL UL listed. The The UL UL certification provides industry leading<br />

level level of of product safety your your customers demand and and the the peace of of mind mind<br />

you you expect from from Eaton. In In business for for over over 100 100 years, Eaton provides<br />

everything your your marina needs for for a safe, a safe, reliable and and efficient electrical<br />

power system.<br />

Learn Learn more more at at marinapower.com<br />

Eaton Eaton Corporation<br />

<strong>Marina</strong> <strong>Marina</strong> Power Power and and Lighting Lighting<br />

1-800-723-8009<br />

marinasales@eaton.com<br />

www.marinapower.com

Hatteras Light Light<br />

Newport Harbor Harbor Mate Mate<br />

Lighthouse & & Lighthouse SS SS<br />

This This compact compact power power pedestal pedestal is is This This shore shore power power option option has has multiple multiple Our Our most most popular popular power power pedestal,<br />

perfect perfect for for providing shore shore power power modular modular mounting options options to fit to your fit your the the Lighthouse offers offers a wide a wide range range<br />

connections to to residential boaters, boaters, personal personal dock dock needs. needs. This This economical, of options of options and and features features meeting meeting the the<br />

private private docks, docks, and and docks docks with with small small device device can can easily easily be installed be installed on onneeds needs of almost of almost any any boater. boater. The The<br />

limited limited space. space.<br />

a dock a dock box box or piling or piling providing providing a minipowepower<br />

a mini-<br />

Lighthouse SS offers SS offers additional<br />

source source to your to your marina. marina.<br />

capabilities and and is made is made with with high high<br />

quality quality stainless stainless steel steel for superior for superior<br />

durability and and performance.<br />

Admiral SS SS<br />

Truly Truly the the flagship flagship of our of our unitized unitized<br />

pedestal pedestal line, line, the the Admiral Admiral SS SS<br />

possesses amperage capabilities and and<br />

receptacles to serve to serve nearly nearly any any size size<br />

Mega Mega Yacht. Yacht.

Floating pontoons<br />

All concrete: the evolution of fixed piers<br />

Made in Italy<br />

Pontoons, breakwaters, piers for super<br />

yachts, floating bridges and constructions:<br />

the best solutions for connecting sea and<br />

land by means of strong and reliable<br />

structures, in aluminium, concrete or steel,<br />

standard or tailor made.<br />

Montecarlo - Monaco: new pontoons at Port Hercule<br />

Let’s shape together<br />

your new marina<br />

Tel. +39 0422 702412<br />

info@ingemar.it<br />

www.ingemar.it<br />

Pontoons and constructions over the water

COVER STORY<br />

The popular fire pit at Provincetown<br />

<strong>Marina</strong> gives boaters a place to drink,<br />

chat and watch the ballgame.<br />

building and replacing slips for boats up<br />

to 125ft (38m).<br />

Now they are working on phase two.<br />

Collaborating again with Boston Bridge<br />

& Steel, the Lagasses have also brought<br />

SF <strong>Marina</strong>s, Meeco Sullivan and <strong>Marina</strong><br />

Electrical Equipment into the project<br />

to create what will be an 8ft (2.4m)<br />

deep, 900ft (274m) long, 20ft (6m) wide<br />

floating breakwater, one of the widest<br />

and deepest on the East Coast. The new<br />

breakwater will include in-slip pump-out<br />

and 480 3-phase power.<br />

The parts for the floating breakwater<br />

and wave attenuation system were<br />

delivered from Sweden this spring,<br />

are currently being assembled in<br />

Provincetown and will require two 36in<br />

(1m) steel piles per 65ft (20m) section.<br />

As <strong>Marina</strong> <strong>World</strong> closed for press, the<br />

piles were being installed and project<br />

completion is scheduled for mid-<strong>May</strong><br />

with a grand opening in <strong>June</strong>.<br />

When looking at the harbour and<br />

the various characteristics of the<br />

location, the Lagasses relied on their<br />

experience with the other marinas they<br />

had developed. “We’ve probably used<br />

every type of dock system available<br />

out there,” Chuck says. “We bought<br />

a hybrid of docks that really fit the<br />

wave environment and the climate of<br />

the waves and fetch. This is more of<br />

a custom-built facility for that specific<br />

geographical location. But, there’s<br />

no individual correct solution. It’s a<br />

combination of things.”<br />

“The one thing we know is how to<br />

build a breakwater in an open harbour<br />

with a lot of exposure to the elements,”<br />

he continues. “We know whether to use<br />

concrete or steel reinforced breakwater<br />

and what type of finger slips, given<br />

location and exposure.”<br />

The new breakwater, shaped<br />

like an elbow extending from the<br />

existing pier, will add approximately<br />

2,000 linear feet (610m), with about<br />

4,000 linear feet (1,219m) available<br />

off the pier. Provincetown Harbor is<br />

currently protected by a 2,500ft (762m)<br />

breakwater built in the early 1970s<br />

about 835ft (255m) from the pier. The<br />

new breakwater will run parallel and<br />

away from that existing breakwater, with<br />

approximately 500ft (152m) between<br />

them, certainly enough room for local<br />

traffic, superyachts and ferries. But<br />

it’s still a significant new feature in the<br />

harbour.<br />

“The narrowest dock is 14ft (4m)<br />

wide and it’s at its widest at 20ft (6m),”<br />

Mason Sears of SF <strong>Marina</strong> says of the<br />

SF <strong>Marina</strong> Type 600. “It looks like a<br />

promenade.” The Type 600 Breakwater<br />

used for the project is SF <strong>Marina</strong>’s<br />

widest off-the-shelf floating breakwater<br />

deployed to the United States - the<br />

widest it has deployed worldwide is in<br />

Italy and comes in at 43ft (13m).<br />

SF <strong>Marina</strong>s and Keco Pumpout<br />

Systems also worked together with<br />

Meeco Sullivan to create an underdeck<br />

pump-out that is flush with the deck<br />

surface, under an aluminium lid with<br />

the hydrant concealed below, while<br />

the fingers provided by Meeco Sullivan<br />

offer “a nice mixture of materials that<br />

provide durability” to offset the harsh<br />

winter conditions and barge waves that<br />

the harbour sees, says Sears.<br />

As part of the original phase of<br />

the project focusing on the landside<br />

amenities and the existing pier, Chuck<br />

and Ann rebuilt the showers and<br />

bathrooms, constructed a new office<br />

facility, added a captain’s lounge<br />

including a fire pit and two large-screen<br />

outdoor televisions to bring customers<br />

in from their moorings, and even<br />

constructed a shower specifically for<br />

dogs.<br />

They also built out an apartment for<br />

the general manager for Provincetown<br />

<strong>Marina</strong> as well as a few staff dorm<br />

rooms since housing in the area can be<br />

challenging for summer employees.<br />

“Provincetown is amazing,” Ann says.<br />

“Things are happening in Newport<br />

[Rhode Island], Nantucket, Martha’s<br />

Vineyard. From an economic point of<br />

view, [the town] knew they were missing<br />

that opportunity. Many of the larger<br />

yachts would anchor out. Now they<br />

have a place to go out, shop and eat.”<br />

Charlestown <strong>Marina</strong>, once crumbling into<br />

the water, sits proudly in Boston Harbor<br />

and is able to moor vessels up to 400ft<br />

(122m) in length.<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 17

Minus

Setting a benchmark in Vietnam<br />

As an emerging tourist destination, Vietnam is enjoying increasing focus on waterfront development for both<br />

recreational and residential purposes. Developing marinas to support interest in yachting lifestyles and to attract<br />

visiting boats meets with the usual stumbling blocks found in countries with little or no legacy of recreational boating –<br />

but entrepreneurs can win through.<br />

Ana <strong>Marina</strong> in Nha Trang on the<br />

south east coast of Vietnam will be<br />

the country’s first world class marina,<br />

initially offering 60 berths for vessels<br />

of 20-40m (66-131ft) and extra wide<br />

berths for catamarans.<br />

Nha Trang is the most vibrant resort<br />

town in Vietnam with an outstandingly<br />

beautiful bay and a wide variety of<br />

beaches and islands. The town has an<br />

international airport, good road and<br />

rail connections and welcomes up to 4<br />

million tourists per annum; around 50%<br />

of the national annual total. With a short<br />

rainy season and low typhoon risk, Nha<br />

Trang is enjoying rapid development<br />

and is further building on its position as<br />

a tourist destination of choice.<br />

Designed by Camper & Nicholson<br />

<strong>Marina</strong>s (CNM), Ana <strong>Marina</strong> features<br />

Marinetek pontoons and Plus Marine<br />

dockside equipment, all of which was<br />

selected via an international tender<br />

process. “With this team of local<br />

developers and international experts,<br />

Ana <strong>Marina</strong> sets the benchmark for<br />

marinas in Vietnam by meeting the<br />

highest and latest international marina<br />

standards,” says Ana <strong>Marina</strong> project<br />

manager, Ruurd van Putten.<br />

CNM provided the project<br />

feasibility and concept design; the<br />

development period design; general<br />

support services; commissioning; and<br />

operations and management support<br />

for the project. Marinetek has provided<br />

a range of berthing options for the<br />

first phase at two 200m (656ft) long x<br />

4m (13ft) wide Heavy Duty pontoons<br />

equipped with open top cable channels<br />

and ‘super yacht bollards’. All berths<br />

have 2.7m (9ft) wide mooring fingers.<br />

Plus Marine is supplying and<br />

installing its HDPE Smart series<br />

pedestals with 16-250amp range, a<br />

Smart Cloud remote metering system,<br />

all piping and cabling, multipoint<br />

vacuum pump-out,<br />

portable fire pumps and<br />

safety illumination.<br />

Future phases will include<br />

a superyacht dock for six<br />

yachts up to 70m (ft) in<br />

length and an additional<br />

100m (328ft) berth is under<br />

consideration.<br />

Landside development<br />

is equally comprehensive<br />

and includes: an atrium as<br />

a central meeting place<br />

and capitainerie; restaurant<br />

and club members’ lounge;<br />

swimming pool and children’s<br />

playground; yacht club bar<br />

and ballroom; gym and spa;<br />

sales offices; and a boatyard<br />

MARINA PLANNING & DESIGN<br />

CGI of Ana <strong>Marina</strong> showing the phase 1<br />

development (Piers B and C) to the left. The<br />

superyacht mooring (Pier A) to the right is<br />

a separate phase.<br />

with hardstand, drystack, slipway and<br />

workshops.<br />

Ana <strong>Marina</strong> will be a gateway to<br />

excellent sailing waters and enjoy a<br />

strategic location between South East<br />

and Northern Asia with convenient<br />

connections to Hong Kong, Sanya,<br />

Singapore, the Philippines, Malaysia,<br />

Indonesia, and other Vietnamese ports.<br />

Developer Ana <strong>Marina</strong> Nha Trang Co<br />

Ltd – a member of Focus Vietnam<br />

Holdings – has a proven track record<br />

in the Vietnamese travel and leisure<br />

industry and is well aware of the<br />

potential of the Ana <strong>Marina</strong> site.<br />

Marinetek will also be flying the<br />

flag for Nha Trang. “We are privileged<br />

to contribute to the first international<br />

status marina project in Vietnam,<br />

opening up a new region and putting<br />

Nha Trang on the world’s yachting<br />

map,” says Marinetek South East Asia<br />

managing director Kristian Räme. “We<br />

are also pleased to be competitive with<br />

our regionally manufactured concrete<br />

pontoons and local project execution<br />

capabilities.”<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 19

THE CENTRAL<br />

PLATFORM<br />

FOR THE GLOBAL<br />

MARINA & YARD INDUSTRY<br />

MEET THE WORLD IN AMSTERDAM<br />

The <strong>Marina</strong> & Yard Pavilion (MYP) features the world’s largest<br />

concentration of equipment suppliers and serves as a meeting place for<br />

marina owners, operators, developers and suppliers from around the<br />

world. In <strong>2017</strong> the MYP will feature the <strong>Marina</strong> Symposium organised<br />

together with the HISWA Holland Association, offering the perfect<br />

platform to learn about and discuss the latest developments worldwide.<br />

Taking place as part of the world’s<br />

largest marine equipment trade show<br />

Exhibitors <strong>Marina</strong> &Yard Pavilion 2016: 64<br />

Number of visits METSTRADE Show 2016: 23,700<br />

The <strong>Marina</strong> & Yard Pavilion is an event of METSTRADE, the world’s leading platform<br />

for professionals in the marine equipment industry.<br />

ORGANISED BY<br />

POWERED BY<br />

OFFICIAL<br />

MAGAZINE<br />

SYP OFFICIAL<br />

MAGAZINE<br />

MYP OFFICIAL<br />

MAGAZINE

MARINA PLANNING & DESIGN<br />

Yachting icon on<br />

Amalfi Coast<br />

<strong>Marina</strong> d’Arechi has become a new yachting icon on the Italian Amalfi Coast<br />

and a symbol of how new enterprise can succeed in southern Italy despite<br />

the impact of global economic crisis. Finally completed at the end of 2016, the<br />

marina ranks as one of the most important tourist facilities ever built in the<br />

region and is a planning and design success story.<br />

Situated in Salerno within a UNESCO<br />

<strong>World</strong> Heritage site, <strong>Marina</strong> d’Arechi<br />

is a destination in its own right and an<br />

ideal homeport or base from which<br />

to explore some of the world’s finest<br />

cruising locations. It offers excellent<br />

access to Positano, Capri, Ischia,<br />

Ravello, Pompeii and Naples.<br />

Enjoying a backdrop of some of the<br />

finest scenery in Italy, the marina is a<br />

modern architectural masterpiece with<br />

an impressive sweeping 1.2km (0.7mi)<br />

breakwater and arched restaurant<br />

buildings. The choice was made to build<br />

the harbour as an island connected<br />

to the mainland by a bridge and the<br />

design is eco-friendly thanks to the use<br />

of natural materials such as the mosaic<br />

style rock breakwater; recycled wood<br />

pontoon decking; and sophisticated<br />

water and waste recycling systems.<br />

With 1,000 berths (80 of which are for<br />

superyachts of 25 to 100m [82 to 328ft])<br />

set within a 34,000m² (366,000ft²)<br />

water basin, <strong>Marina</strong> d’Arechi caters for<br />

sail and motor yachts of 10 to 100m (33<br />

to 328ft) and prides itself on providing<br />

the ultimate lifestyle for vessel owners,<br />

with luxury and comfort at its core. Little<br />

touches and attention to detail make<br />

for exceptional service, and the marina<br />

team is dedicated to making yacht<br />

owners, captains and crew feel both ‘at<br />

home’ and on holiday.<br />

The concept for the marina was the<br />

With a perfect geographical location and<br />

the latest ecologically friendly amenities,<br />

<strong>Marina</strong> d’Arechi is a symbol of success in<br />

southern Italy.<br />

brainchild of Agostino Gallozzi, chairman<br />

of both shipping business specialist<br />

Gallozzi Group and <strong>Marina</strong> d’Arechi. The<br />

group, which is the majority shareholder<br />

in the marina (68%), invested €120<br />

million in the project, €80 million of<br />

which was concentrated on the marina<br />

infrastructure; and the expense was in<br />

part due to passion.<br />

“For anyone living in Salerno, sailing<br />

and yachting on the Amalfi Coast is<br />

the ideal way of enjoying weekends<br />

and holidays with friends and family<br />

throughout the year. From the age of 15<br />

sailing the Mediterranean waters I visited<br />

so many marinas, none of which really<br />

satisfied me 100%,” Gallozzi said. “Over<br />

time, I developed the idea of building<br />

the ultimate marina: the amalgamation<br />

of all my nautical experiences, the result<br />

of my passion for the sea, in my own<br />

town – where the sunset is breathtaking<br />

and summer never ends. It had to be an<br />

amazing marina, beautiful and perfect,<br />

safe, comfortable, friendly and enjoyable<br />

every day of the year, state of the art in<br />

technology, the place where you want to<br />

be all the time.”<br />

Although the project began in 2000,<br />

it took a decade for the first stone to be<br />

laid. A series of complex administrative<br />

and legislative procedures and the<br />

economic crash intervened. But by<br />

summer 2012 – two years later – the<br />

first berths were inaugurated and the<br />

first yachts welcomed. In just four<br />

further years, a 1,000-berth marina with<br />

a complex surrounding infrastructure<br />

was in place. Facilities include a<br />

Friendly, efficient and multi-lingual, the<br />

marina team aims to make all visitors feel<br />

‘at home’ when on holiday.<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 21

Providing independent and bespoke services to clients worldwide<br />

Masterplanning<br />

Feasibility studies and market research<br />

Business planning<br />

<strong>Marina</strong> and <strong>Marina</strong> Club design<br />

Investment appraisal<br />

Tender and project management<br />

Environmental and legislative advice<br />

Legal and property consultancy services

MARINA PLANNING & DESIGN<br />

<strong>Marina</strong> d’Arechi welcomes large vessels<br />

and has 80 berths set aside for yachts<br />

of 25m (82ft) and above.<br />

full service shipyard that offers<br />

comprehensive repair and maintenance<br />

services to all berth holders; a bunker<br />

station with 14 fuel dispensers; sport<br />

and wellness facilities; bar, restaurants,<br />

patisserie, shops and private beach.<br />

Safety and security are paramount,<br />

and marina manager Anna<br />

Cannavacciuolo and her team<br />

have an impressive environmental<br />

management programme. The marina<br />

holds the highest rating in the 24PLUS<br />

certification for quality of services<br />

dedicated to superyachts, is a member<br />

of The Yacht Harbour Association and is<br />

ISO 9000 certified. It was awarded the<br />

Blue Flag 2016/<strong>2017</strong> for marinas and<br />

is further recognised in an annual audit<br />

carried out by Rina – the Italian naval<br />

register.<br />

Having completed its final 350 brand<br />

new berths for boats of 14 to 50m (46<br />

to 164ft) by the end of 2016, <strong>Marina</strong><br />

d’Arechi made a New Year resolution to<br />

implement an aggressive sales push on<br />

Italian and international markets; selling<br />

a destination as well as a berth. It has<br />

also sought out international marina<br />

management and operational support,<br />

marketing insight and general expertise<br />

from Camper & Nicholsons <strong>Marina</strong>s<br />

(CNM) and has joined CNM’s 1782<br />

Club B2B initiative.<br />

Dan Hughes, business development<br />

director at CNM, has been in close<br />

touch with Agostino Gallozzi and the<br />

marina for several years and is delighted<br />

that the CNM team can now help put<br />

the marina on the map. “<strong>Marina</strong> d’Arechi<br />

fits in perfectly with the Camper &<br />

Nicholsons <strong>Marina</strong>s family,” he said. “The<br />

service is friendly yet professional, which<br />

makes for a great atmosphere around<br />

the marina, and all staff are fluent in<br />

Italian and English, with others speaking<br />

a third language. This truly is an<br />

international superyacht marina for the<br />

21 st century and a welcoming homeport<br />

for all who wish to enjoy the relaxed,<br />

luxury lifestyle on offer.”<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 23

Windsor Racecourse <strong>Marina</strong><br />

handling<br />

and lifting<br />

systems<br />

www.boatlift.it<br />

info@boatlift.it<br />

Tel. +39(0)173 500357<br />

Fax +39(0)173 500642

MARINA PLANNING & DESIGN<br />

OpenStreetMap<br />

From home-grown<br />

to high-tech on a<br />

Māori lake<br />

Caution: this is a story of renewal and expansion in New Zealand that contains<br />

a number of challenging Māori names. Be undaunted. It’s an inspirational<br />

story well worth the effort. Robert Wilkes reports.<br />

Lake Taupō is considered the<br />

“beating heart” of the North Island by<br />

Māori. The lake bed is formed by a<br />

huge volcanic crater and is owned by<br />

Ngati Tūwharetoa, a Māori tribe<br />

made up of 26 hapū, or sub-tribes.<br />

Motuoapa <strong>Marina</strong> nestles on the<br />

shore of a village of the same name.<br />

Now that you have mastered these<br />

challenging Māori names, we begin.<br />

New Zealand is a new land that<br />

rose from the sea as the result of<br />

the massive collision of tectonic<br />

plates. Lake Taupō is in a volcano<br />

caldera or crater formed by multiple<br />

eruptions over 300,000 years. The<br />

last major eruption 1,800 years<br />

ago may have been the natural<br />

phenomenon noted at the time by<br />

chroniclers in China and Rome.<br />

Located in the middle of the North<br />

Island, the 623km² (240.5mi²) lake is the<br />

largest in New Zealand. Major population<br />

centres are three hours south and north,<br />

notably Wellington and Auckland. The lake<br />

is dotted with stunning cliff-side<br />

Māori carvings and visitors enjoy<br />

fishing excursions and adventure<br />

tours. Remarkably, but not in New<br />

Zealand, there are ski resorts not<br />

more than 30 minutes away.<br />

The original marina was built 50 to 60<br />

years ago by local boating enthusiasts<br />

and members of social organisations<br />

who wanted a place to keep a boat<br />

on the lake. They did it with grit and<br />

sweat on weekends. They created a<br />

cozy marina for family boating in a<br />

beautiful setting; some say it has the<br />

greatest trout fishing in the world. All<br />

the slips are permanently rented by<br />

local residents and boaters who drive<br />

up from the cities.<br />

Ready for renewal<br />

Unfortunately, there were no<br />

hydrologists among the volunteers.<br />

While the lake water just outside the<br />

marina is always pristine, the water<br />

The all-new Motuoapa <strong>Marina</strong> (above)<br />

now dominates the centre of the basin<br />

– a far better and more convenient<br />

arrangement than the perimeter mooring<br />

(right).<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 25

MARINA PLANNING & DESIGN<br />

inside did not flush and was stagnant,<br />

algae-choked and infested with<br />

invasive catfish. There were plenty of<br />

other issues. An island took up valuable<br />

space in the middle of the basin. Boats<br />

berthed around the perimeter were<br />

pile-tied with their bows to a crumbling<br />

timber sea wall. The ‘boaties’ - many<br />

of them ageing - had to clamber onto<br />

the pointy end with their groceries in<br />

their arms and shuffle alongside the<br />

deckhouse to the cockpit.<br />

Motuoapa <strong>Marina</strong> was loved, but long<br />

past its useful life. There was no water,<br />

no electricity, no security, no lighting<br />

and no services. Part of the marina was<br />

on the boundary of private land and half<br />

the boaters were effectively trespassing<br />

to get to their boats. Worst of all, due<br />

to a lake level that fluctuates by 1.4m<br />

(4.6ft) over a year, boaters couldn’t<br />

access their berths or navigate the<br />

channel during low water.<br />

And you think your marina has<br />

problems!<br />

Taking charge<br />

As noted, the lakebed is owned by<br />

Ngāti Tūwharetoa. The lake boating<br />

facilities are owned by the ‘Crown’<br />

(as the New Zealand Government<br />

is called), and managed by the<br />

Department of Internal Affairs (DIA).<br />

The Lake Taupō harbourmaster is<br />

employed by DIA, and is responsible<br />

for the maintenance, upkeep and safety<br />

of four marinas, numerous jetties and<br />

17 boat ramps. The harbourmaster’s<br />

office is in Taupō, 40km (25mi) north of<br />

Motuoapa. The tribe, as owner of the<br />

lakebed, receives an annual payment<br />

from the Crown for providing access<br />

to Lake Taupō and its permission is<br />

required for any renewal project.<br />

The DIA harbourmaster, Philip<br />

King, completed a career as a<br />

superyacht captain in the Caribbean<br />

and returned to New Zealand to<br />

settle down and start a family. He<br />

became harbourmaster in 2008<br />

and in 2009 initiated a survey of all<br />

the Crown assets on the lake. The<br />

renovation of Motuoapa <strong>Marina</strong> was<br />

high on the list of projects and had<br />

been on the drawing board since the<br />

late 1990s.<br />

King and the DIA developed an<br />

asset management plan and went to<br />

the Crown with a proposal for funds<br />

for capital improvements. The plan<br />

was approved in 2011. “Prior to the<br />

asset management plan we had<br />

NZ$34,000 for capital improvements<br />

on the entire lake,” said King, “which<br />

was impossible. During our planning<br />

phase we touched base with<br />

Bellingham Marine for some concept<br />

ideas that we needed and they were<br />

helpful.”<br />

In 2015 the DIA approved NZ$6<br />

million for the Motuoapa <strong>Marina</strong><br />

project. Tenders were offered<br />

and several dock manufacturers<br />

and civil engineering companies<br />

responded. Seay Earthmovers, a<br />

local company based in Taupō, won<br />

the bid for the civil work. Bellingham<br />

Marine was named contractor for<br />

the docks and dock installation. “We<br />

had several competitive bids and<br />

chose Bellingham Marine based on<br />

reputation, technology and cost,”<br />

King explained. “We liked some of<br />

the product differences they offered,<br />

particularly the new FRP thru-rods.”<br />

Consent and planning<br />

The original<br />

marina was built<br />

by the community<br />

well before<br />

resource consent<br />

applications were<br />

required. Acquiring<br />

resource consent<br />

to build a marina<br />

in New Zealand is<br />

long and requires<br />

patience. The<br />

public consultation<br />

process included<br />

boat owners, the<br />

local community,<br />

government<br />

The lake region is rich in Mãori culture (above)<br />

and the home of the world’s most threatened gull<br />

species; the black-billed gull (below).<br />

Pontoons lined up in the newly cleared<br />

basin awaiting configuration.<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 27

Kropf Industrial also supplies a full line<br />

of hydraulic boat trailers, as well as<br />

steel tube floating dock systems and<br />

floating breakwaters.<br />

www.kropfindustrial.com info@kropfindustrial.com 888.480.3777<br />

Martini <strong>Marina</strong>s<br />

floating pontoons.<br />

The best, from all<br />

points of the compass.<br />

Mets Amsterdam<br />

15/17 November 2016<br />

stand MYP05.409<br />

Martini Alfredo S.p.A.<br />

Via Centro Industriale Europeo, 43<br />

P.O. Box 30 - 22078 Turate (CO) - Italy<br />

Tel +39 02 963941 - Fax +39 02 9682613<br />

marinas.export@martinialfredo.it<br />

www.martinialfredo.it<br />

Switzerland T. +41 91 9945545 info@interbox.ch<br />

Croatia T. +385 1 6530103 stp@stp-croatia.com<br />

Greece T. +30 23 10692899 makis@zaggas-group.gr<br />

Netherlands / Belgium T. +31 6 46140603<br />

info@aquamore.info

MARINA PLANNING & DESIGN<br />

Unifloat pontoons with rounded end finger<br />

piers being installed to create a 158-slip<br />

arrangement.<br />

departments and the Māori hapū,<br />

whose permission was required. “We<br />

had extensive consultations with the<br />

affected hapū and got their support,”<br />

King confirmed. “We also had to<br />

address environmental and cultural<br />

issues and file the required studies and<br />

reports.”<br />

Twenty-seven variations of the design<br />

were considered before a consensus<br />

was reached. “We had been focusing<br />

on a berth configuration similar to the<br />

existing layout when a couple of my<br />

team (Alex Dickie and Rod Vennell)<br />

suddenly had a penny-drop moment<br />

and saw it in a new way. Now it seems<br />

so obvious. We’re very confident in the<br />

final design and layout,” he said.<br />

Bruce Birtwistle, general manager<br />

Bellingham Marine, added: “The<br />

process was further complicated<br />

because this is the first project the DIA<br />

has done of this kind in the interior.<br />

They are not normally involved in the<br />

marina business. Working with the DIA<br />

team has proved rewarding. They have<br />

been quick to accept ideas and make<br />

them work.”<br />

Cleaning the site<br />

Lake Taupō is a world famous trout<br />

fishery, with brown and rainbow trout<br />

introduced in the late 1900s from North<br />

American stock. The redevelopment of<br />

the site required humane removal of all<br />

fish prior to dredging or construction.<br />

Crews captured 3,000 catfish living<br />

in the basin and recycled them for<br />

fertilizer. “The catfish are an invasive<br />

pest,” said King. “They compete with<br />

trout for food sources and eat juvenile<br />

trout. We were delighted to reduce the<br />

catfish population.”<br />

Earthworks and dredging began in<br />

2016. The work included excavation<br />

and removal of the island, and a<br />

reclamation of part of the lake. The<br />

design implemented a zero cut to<br />

fill balance of the dredged material<br />

(approximately 40,000m³ [52,318yd³]),<br />

which formed the reclamation. Seay<br />

Earthmovers also owns a quarry and<br />

supplied the boulders for the sea wall<br />

protecting the reclamation.<br />

The opening of the new marina was<br />

scheduled for April, but is delayed until<br />

July <strong>2017</strong>. The old timber wall proved<br />

fragile and failed in several places<br />

during dredging. Seay and Bellingham<br />

Marine have been asked to replace it<br />

with steel sheet pile. Additionally, work<br />

in parts of the site was halted with the<br />

arrival of nesting black-billed gulls,<br />

which have the distinction of being the<br />

most threatened gull species in the<br />

world.<br />

New technology pontoons<br />

The marina’s new Unifloat pontoons<br />

are arranged in a 158 slip configuration<br />

with rounded-end finger-pier berths<br />

from 8 to 14m (26 to 46ft) in length.<br />

The pontoons have New Zealandgrown<br />

treated pine walers, aluminium<br />

pile guides, aluminium gangways and<br />

security gates. There will be power<br />

pedestals and potable water at the<br />

slips.<br />

The pontoons incorporate FRP ‘thrurods’<br />

and nylon nuts manufactured<br />

by pultrusion (the material is pulled<br />

through a die rather than pushed as in<br />

the more common extrusion process).<br />

The FRP thru-rods are corrosion free<br />

and are sufficiently resilient to retain<br />

tension over time, virtually eliminating<br />

the need to retighten the nuts. The FRP<br />

thru-rods contribute to the corrosion<br />

resistance and low-maintenance of the<br />

dock system.<br />

The docks were manufactured in<br />

Auckland and transported to the site by<br />

truck. Bellingham Marine’s Auckland<br />

plant serves New Zealand and the<br />

South Pacific as far as Guam.<br />

Quality water<br />

The water quality situation was critical.<br />

“We installed a fresh water pumping<br />

system that extends 400m (1,312ft)<br />

outside of the marina,” King confirmed.<br />

“We have a 400m pipe with 500mm<br />

(19.6in) diameter that will pick up<br />

pristine water from 3m (10ft) deep<br />

where the water is cooler and pump<br />

it into the marina at 200 litres (44<br />

galls) per second. <strong>Marina</strong> water will be<br />

refreshed every 72 hours and it takes<br />

72 hours for algae to form. Our threepronged<br />

approach to defeat algae is<br />

cool water, fresh water and constant<br />

movement. We’ll be able to see the<br />

lake bottom through pristine water and<br />

we anticipate trout and smelt will form<br />

habitat in the basin.”<br />

A public resource<br />

The new marina will be a vast<br />

improvement, with water, electricity,<br />

secure gangways, bathroom facilities<br />

and a quadruple boat ramp. “We are<br />

creating a beach and a large green<br />

space. The community has never had<br />

a swimming beach and we’re looking<br />

forward to seeing families there,” King<br />

noted. “This is not a bigshot developer<br />

project. We are creating a public<br />

resource. But we would like to think that<br />

the new marina will be the catalyst for<br />

economic development, especially for<br />

southern Lake Taupō.”<br />

Bellingham’s Birtwistle said: “Philip<br />

King brought the energy and patience<br />

to work with the various groups and<br />

stakeholders to bring the project across<br />

the line. He wanted to do it right and he<br />

had the vision to see the potential. He<br />

can look back with satisfaction at what<br />

has been accomplished.”<br />

Robert Wilkes writes about the<br />

marina industry from Bellevue,<br />

Washington, USA.<br />

www.marinaworld.com - <strong>May</strong>/<strong>June</strong> <strong>2017</strong> 29

on the water and everywhere<br />

EUROPA I AMERICAS I MIDDLE EAST I ASIA I AUSTRALIA<br />

Canoe Brook,<br />

New Jersey, USA - Objective: 136,000 kWh!<br />

The floating solar system set up close to New York is at peak output.<br />

More than 8,000 references over 5 continents

MANUFACTURER OF PONTOONS AND MARINA EQUIPMENT<br />

" An innovative installation producing<br />

renewable energy, designed and<br />

built with the specialists in floating<br />

structures"<br />

The Canoe Brook solar energy power plant has been in operation since summer 2011,<br />

and the energy produced there is set to power a New Jersey water treatment plant.<br />

The objective of this floating solar system when fully set up and in operation is thus to<br />

generate 136,000 kWh of energy each year.<br />

To make this happen, a partnership has been established between Eneractive Solutions<br />

(energy solutions), Seaflex (anchorage) and Poralu Marine (floating platforms).<br />

Through its Canadian subsidiary, Poralu Marine, a manufacturer of equipment for nautical<br />

infrastructures, was able to provide comprehensive solutions to the project’s many<br />

constraints: budget, stability, longevity, resistance to ice and reduced maintenance.<br />

Solar energy is central to my reflections about the future of our environment.<br />

I have confidence in the quality of Poralu Marine’s R&D services to continue innovating<br />

and providing new processes.<br />

David S. Klockner<br />

Vice President & Chief Operating Officer,<br />

Eneractive Solutions<br />

www.poralu.com

Hazelett<br />

Marine<br />

Conservation Elastic<br />

Mooring Systems<br />

For Yachts and Docks<br />

www.hazelettmarine.com<br />

135 West Lakeshore Drive, PO Box 600<br />

Colchester, Vermont 05446-0600<br />

EMAIL: info@hazelettmarine.com<br />

TELEPHONE: (802) 863-6376<br />

FAX: (802) 863-1523

MARINA PLANNING & DESIGN<br />

St Katharine Docks is a vibrant mixeduse<br />

marina oasis in the heart of Central<br />

London.<br />

Luxury berthing in the<br />

heart of London<br />

The newly refurbished marina at St Katharine Docks (SKD) in London is now<br />

complete. Able to accommodate superyachts up to 40m (131ft) long, it has<br />