CPT International 01/2016

The leading technical journal for the global foundry industry – Das führende Fachmagazin für die weltweite Gießerei-Industrie

The leading technical journal for the

global foundry industry – Das führende Fachmagazin für die

weltweite Gießerei-Industrie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

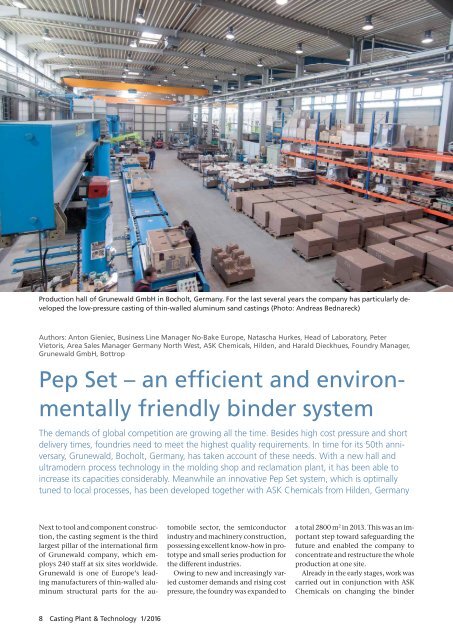

Production hall of Grunewald GmbH in Bocholt, Germany. For the last several years the company has particularly developed<br />

the low-pressure casting of thin-walled aluminum sand castings (Photo: Andreas Bednareck)<br />

Authors: Anton Gieniec, Business Line Manager No-Bake Europe, Natascha Hurkes, Head of Laboratory, Peter<br />

Vietoris, Area Sales Manager Germany North West, ASK Chemicals, Hilden, and Harald Dieckhues, Foundry Manager,<br />

Grunewald GmbH, Bottrop<br />

mentally<br />

friendly binder system<br />

The demands of global competition are growing all the time. Besides high cost pressure and short<br />

delivery times, foundries need to meet the highest quality requirements. In time for its 50th anniversary,<br />

Grunewald, Bocholt, Germany, has taken account of these needs. With a new hall and<br />

ultramodern process technology in the molding shop and reclamation plant, it has been able to<br />

increase its capacities considerably. Meanwhile an inno vative Pep Set system, which is optimally<br />

tuned to local processes, has been developed together with ASK Chemicals from Hilden, Germany<br />

Next to tool and component construction,<br />

the casting segment is the third<br />

largest pillar of the international firm<br />

of Grunewald company, which employs<br />

240 staff at six sites worldwide.<br />

Grunewald is one of Europe‘s leading<br />

manufacturers of thin-walled aluminum<br />

structural parts for the automobile<br />

sector, the semiconductor<br />

industry and machinery construction,<br />

possessing excellent know-how in prototype<br />

and small series production for<br />

the different industries.<br />

Owing to new and increasingly varied<br />

customer demands and rising cost<br />

pressure, the foundry was expanded to<br />

a total 2800 m 2 in 2<strong>01</strong>3. This was an important<br />

step toward safeguarding the<br />

future and enabled the company to<br />

concentrate and restructure the whole<br />

production at one site.<br />

Already in the early stages, work was<br />

carried out in conjunction with ASK<br />

Chemicals on changing the binder<br />

8 Casting Plant & Technology 1/2<strong>01</strong>6