CPT International 02/2016

The leading technical journal for the global foundry industry – Das führende Fachmagazin für die weltweite Gießerei-Industrie

The leading technical journal for the

global foundry industry – Das führende Fachmagazin für die

weltweite Gießerei-Industrie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

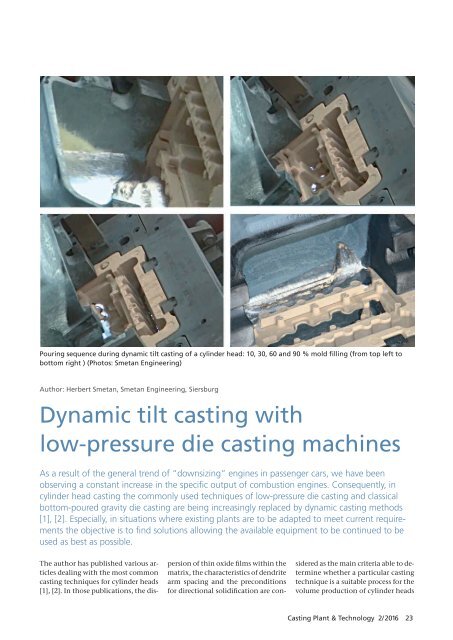

Pouring sequence during dynamic tilt casting of a cylinder head: 10, 30, 60 and 90 % mold filling (from top left to<br />

bottom right ) (Photos: Smetan Engineering)<br />

Author: Herbert Smetan, Smetan Engineering, Siersburg<br />

Dynamic tilt casting with<br />

low-pressure die casting machines<br />

As a result of the general trend of “downsizing” engines in passenger cars, we have been<br />

observingaconstantincreaseinthespecificoutputofcombustionengines.Consequently,in<br />

cylinderheadcastingthecommonlyusedtechniquesoflow-pressurediecastingandclassicalbottom-pouredgravitydiecastingarebeingincreasinglyreplacedbydynamiccastingmethods<br />

[1],[2].Especially,insituationswhereexistingplantsaretobeadaptedtomeetcurrentrequirementstheobjectiveistofindsolutionsallowingtheavailableequipmenttobecontinuedtobeusedasbestaspossible.<br />

The author has published various articles<br />

dealing with the most common<br />

casting techniques for cylinder heads<br />

[1], [2]. In those publications, the dispersion<br />

of thin oxide films within the<br />

matrix, the characteristics of dendrite<br />

arm spacing and the preconditions<br />

for directional solidification are considered<br />

as the main criteria able to determine<br />

whether a particular casting<br />

technique is a suitable process for the<br />

volume production of cylinder heads<br />

Casting Plant & Technology 2/<strong>2016</strong> 23