RiskUKSeptember2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Gaseous Fixed Firefighting Systems:<br />

Design, Selection and Installation<br />

The whole process has<br />

taken six months and<br />

significant input from<br />

a range of experts, but<br />

the Fire Industry<br />

Association has now<br />

published a new<br />

guidance document<br />

designed to demystify<br />

the standards<br />

surrounding the<br />

design, selection and<br />

installation of gaseous<br />

fixed firefighting<br />

system pipework. Alan<br />

Elder and Robert<br />

Thilthorpe address the<br />

all-important points to<br />

note for fire safety<br />

professionals<br />

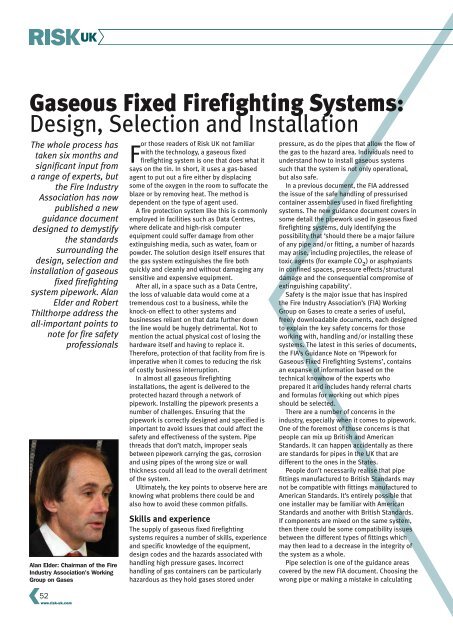

Alan Elder: Chairman of the Fire<br />

Industry Association’s Working<br />

Group on Gases<br />

52<br />

www.risk-uk.com<br />

For those readers of Risk UK not familiar<br />

with the technology, a gaseous fixed<br />

firefighting system is one that does what it<br />

says on the tin. In short, it uses a gas-based<br />

agent to put out a fire either by displacing<br />

some of the oxygen in the room to suffocate the<br />

blaze or by removing heat. The method is<br />

dependent on the type of agent used.<br />

A fire protection system like this is commonly<br />

employed in facilities such as Data Centres,<br />

where delicate and high-risk computer<br />

equipment could suffer damage from other<br />

extinguishing media, such as water, foam or<br />

powder. The solution design itself ensures that<br />

the gas system extinguishes the fire both<br />

quickly and cleanly and without damaging any<br />

sensitive and expensive equipment.<br />

After all, in a space such as a Data Centre,<br />

the loss of valuable data would come at a<br />

tremendous cost to a business, while the<br />

knock-on effect to other systems and<br />

businesses reliant on that data further down<br />

the line would be hugely detrimental. Not to<br />

mention the actual physical cost of losing the<br />

hardware itself and having to replace it.<br />

Therefore, protection of that facility from fire is<br />

imperative when it comes to reducing the risk<br />

of costly business interruption.<br />

In almost all gaseous firefighting<br />

installations, the agent is delivered to the<br />

protected hazard through a network of<br />

pipework. Installing the pipework presents a<br />

number of challenges. Ensuring that the<br />

pipework is correctly designed and specified is<br />

important to avoid issues that could affect the<br />

safety and effectiveness of the system. Pipe<br />

threads that don’t match, improper seals<br />

between pipework carrying the gas, corrosion<br />

and using pipes of the wrong size or wall<br />

thickness could all lead to the overall detriment<br />

of the system.<br />

Ultimately, the key points to observe here are<br />

knowing what problems there could be and<br />

also how to avoid these common pitfalls.<br />

Skills and experience<br />

The supply of gaseous fixed firefighting<br />

systems requires a number of skills, experience<br />

and specific knowledge of the equipment,<br />

design codes and the hazards associated with<br />

handling high pressure gases. Incorrect<br />

handling of gas containers can be particularly<br />

hazardous as they hold gases stored under<br />

pressure, as do the pipes that allow the flow of<br />

the gas to the hazard area. Individuals need to<br />

understand how to install gaseous systems<br />

such that the system is not only operational,<br />

but also safe.<br />

In a previous document, the FIA addressed<br />

the issue of the safe handling of pressurised<br />

container assemblies used in fixed firefighting<br />

systems. The new guidance document covers in<br />

some detail the pipework used in gaseous fixed<br />

firefighting systems, duly identifying the<br />

possibility that ‘should there be a major failure<br />

of any pipe and/or fitting, a number of hazards<br />

may arise, including projectiles, the release of<br />

toxic agents (for example CO 2 ) or asphyxiants<br />

in confined spaces, pressure effects/structural<br />

damage and the consequential compromise of<br />

extinguishing capability’.<br />

Safety is the major issue that has inspired<br />

the Fire Industry Association’s (FIA) Working<br />

Group on Gases to create a series of useful,<br />

freely downloadable documents, each designed<br />

to explain the key safety concerns for those<br />

working with, handling and/or installing these<br />

systems. The latest in this series of documents,<br />

the FIA’s Guidance Note on ‘Pipework for<br />

Gaseous Fixed Firefighting Systems’, contains<br />

an expanse of information based on the<br />

technical knowhow of the experts who<br />

prepared it and includes handy referral charts<br />

and formulas for working out which pipes<br />

should be selected.<br />

There are a number of concerns in the<br />

industry, especially when it comes to pipework.<br />

One of the foremost of those concerns is that<br />

people can mix up British and American<br />

Standards. It can happen accidentally as there<br />

are standards for pipes in the UK that are<br />

different to the ones in the States.<br />

People don’t necessarily realise that pipe<br />

fittings manufactured to British Standards may<br />

not be compatible with fittings manufactured to<br />

American Standards. It’s entirely possible that<br />

one installer may be familiar with American<br />

Standards and another with British Standards.<br />

If components are mixed on the same system,<br />

then there could be some compatibility issues<br />

between the different types of fittings which<br />

may then lead to a decrease in the integrity of<br />

the system as a whole.<br />

Pipe selection is one of the guidance areas<br />

covered by the new FIA document. Choosing the<br />

wrong pipe or making a mistake in calculating