- Page 1 and 2: Copyright by Todd Christopher Baile

- Page 3 and 4: Imprint Template Advances and Surfa

- Page 5 and 6: Dedication This is dedicated to my

- Page 7 and 8: I want to thank those who aided in

- Page 9 and 10: mitigation of the shift in feature

- Page 11 and 12: Chapter 4: Review of the Reaction o

- Page 13 and 14: Appendix D: Conversion of KLA Data

- Page 15 and 16: List of Figures Figure 1.1. Schemat

- Page 17 and 18: Figure 5.3: Water contact angle and

- Page 19 and 20: Figure 7.25: Images captured during

- Page 21 and 22: Figure B.8: Program diagram for Swi

- Page 23 and 24: “source” and “drain” region

- Page 25 and 26: computing power is required. Microp

- Page 27 and 28: Photoresist Substrate Mask hυ hυ

- Page 29 and 30: Tool Price ($) $100,000,000 $10,000

- Page 31 and 32: material. This material takes the s

- Page 33 and 34: planarizing/transfer layer was coat

- Page 35 and 36: patterned relief structures is alig

- Page 37 and 38: Contact lithography predates the pr

- Page 39 and 40: 8. Chou, S.Y., P.R. Krauss, and P.J

- Page 41 and 42: SFIL IMPRINT PROCESS DEVELOPMENT Ch

- Page 43 and 44: substrate that changes in chemical

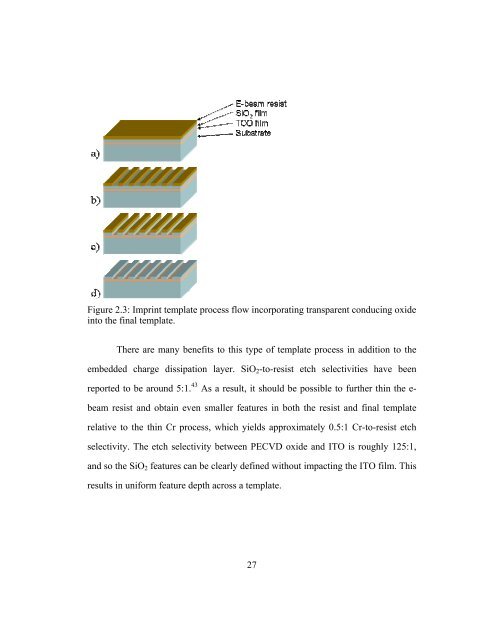

- Page 45 and 46: In modern photomask production, imp

- Page 47: and CD-SEM inspection, and also all

- Page 51 and 52: quartz substrates. Percent transmis

- Page 53 and 54: a) b) Figure 2.5: (a) 30 nm trenche

- Page 55 and 56: nm, so the normalization to film th

- Page 57 and 58: with increasing anneal time, up to

- Page 59 and 60: 2.12 shows line/space features poss

- Page 61 and 62: a) b) Figure 2.14: SEM micrographs

- Page 63 and 64: a) c) e) Index Index Index 2.7 2.5

- Page 65 and 66: function of ITO thickness is much g

- Page 67 and 68: esidual layer only. The right plot

- Page 69 and 70: it is mentioned here for context. T

- Page 71 and 72: Some results are shown in Figure 2.

- Page 73 and 74: 5. Widden, T.K., et al., Nanotechno

- Page 75 and 76: 45. Lewis, B.G. and D.C. Paine, MRS

- Page 77 and 78: 3.1 BACKGROUND Chapter 3: SFIL Etch

- Page 79 and 80: 3.2 EXPERIMENTAL For the imprinting

- Page 81 and 82: The fluorinated additive experiment

- Page 83 and 84: Formulation M2 did not polymerize.

- Page 85 and 86: adhesive forces at the two interfac

- Page 87 and 88: Chapter 4: Review of the Reaction o

- Page 89 and 90: such as annealing. Each of these ex

- Page 91 and 92: on colloidal silica particles. 9 He

- Page 93 and 94: Figure 4.2: From Chuang, et al. 16

- Page 95 and 96: was achieved by exposing the surfac

- Page 97 and 98: Cras, et al. 37 compared various we

- Page 99 and 100:

where X is either an alkoxy group o

- Page 101 and 102:

with increasing temperature. They a

- Page 103 and 104:

from liquid and supercritical CO2.

- Page 105 and 106:

hydrolyzed intermediates. These res

- Page 107 and 108:

limiting film thickness. This is in

- Page 109 and 110:

authors observed a decrease in the

- Page 111 and 112:

to form SAM films of at least moder

- Page 113 and 114:

was able to predict the networking

- Page 115 and 116:

39. Ruzyllo, J., et al., Proc. Elec

- Page 117 and 118:

77. Allara, D., A.N. Parikh, and F.

- Page 119 and 120:

Chapter 5: SFIL Imprint Template Re

- Page 121 and 122:

5.1.3 Self-Assembled Monolayer Rele

- Page 123 and 124:

ITO, followed by plasma-enhanced ch

- Page 125 and 126:

5.3 RESULTS AND DISCUSSION 5.3.1 Fu

- Page 127 and 128:

a) b) Water Contact Angle F:Si Area

- Page 129 and 130:

Imprinting Durability of FOTS on Fu

- Page 131 and 132:

At the time of this writing, no oth

- Page 133 and 134:

Methanol adsorption below 130 K fol

- Page 135 and 136:

of the SiO2 layer to define the tem

- Page 137 and 138:

treatment films of at least modest

- Page 139 and 140:

imprinting durability. Due to the r

- Page 141 and 142:

Chapter 6: Effect of Substrate Hydr

- Page 143 and 144:

The Ag 3d5/2 XPS peak at 368.3 eV f

- Page 145 and 146:

dθ Equation 6.8 ( ) 2 OH , 3 3 −

- Page 147 and 148:

Concentration (nm -2 ) 5 4.5 4 3.5

- Page 149 and 150:

Mass (mg) 14 13.9 13.8 13.7 13.6 13

- Page 151 and 152:

silanol coverage for temperatures b

- Page 153 and 154:

increasing film density with increa

- Page 155 and 156:

7.1 INTRODUCTION DEFECT ANALYSIS FO

- Page 157 and 158:

The fundamental question to be answ

- Page 159 and 160:

placement in the die array must be

- Page 161 and 162:

an exposure source that is used to

- Page 163 and 164:

the transfer layer. The BARC was sp

- Page 165 and 166:

Figure 7.5: UT MER South cleanroom

- Page 167 and 168:

English rating denotes the number o

- Page 169 and 170:

wall of the cleanroom was a large c

- Page 171 and 172:

The results of the particles genera

- Page 173 and 174:

the wafer chuck, and we have attemp

- Page 175 and 176:

7.4 RESULTS & DISCUSSION 7.4.1 Temp

- Page 177 and 178:

a) that protects the master from co

- Page 179 and 180:

determines the absolute value of co

- Page 181 and 182:

a) b) c) Figure 7.16: Resist images

- Page 183 and 184:

Figure 7.18: Evolution of slope (so

- Page 185 and 186:

Figure 7.19: SSE for the data in Fi

- Page 187 and 188:

and 92 in the denominator is 3.95;

- Page 189 and 190:

a) b) Figure 7.22: (a) Obvious patt

- Page 191 and 192:

Table 7.1: Percent standard error i

- Page 193 and 194:

a) c) e) Defect Density (cm -2 ) De

- Page 195 and 196:

defect bins reveal an increase in d

- Page 197 and 198:

detected defects in one particular

- Page 199 and 200:

imprints show little or no increase

- Page 201 and 202:

a) b) Defect Density (cm -2 ) Defec

- Page 203 and 204:

Figure 7.35 shows a defect composed

- Page 205 and 206:

a) b) c) d) e) f) g) h) i) j) k) Fi

- Page 207 and 208:

a) b) c) Figure 7.34: Example defec

- Page 209 and 210:

a) b) c) Figure 7.36: Example defec

- Page 211 and 212:

Figure 7.37: Stress-strain comparis

- Page 213 and 214:

7.6 CONCLUSIONS The SFIL cleanroom

- Page 215 and 216:

Chapter 8: Effect of Film thickness

- Page 217 and 218:

8.2 EXPERIMENTAL A Woollam M-2000 s

- Page 219 and 220:

a) b) Figure 8.4. (a) Irradiance sp

- Page 221 and 222:

intensity of the Xe lamp, and RspCC

- Page 223 and 224:

a) b) Contrast Contrast 10 9 8 7 6

- Page 225 and 226:

a) b) Figure 8.7. Contrast response

- Page 227 and 228:

a) b) c) Transfer Layer Thickness (

- Page 229 and 230:

contrast prior to subsequent etchin

- Page 231 and 232:

The etch barrier imprinting fidelit

- Page 233 and 234:

evaluation needs to be undertaken t

- Page 235 and 236:

where η0 and ηm are the optical a

- Page 237 and 238:

N_SiO2 = SiO2(2,2:3); t_SiO2 = 100;

- Page 239 and 240:

SFILCalc.m function data = SFILcalc

- Page 241 and 242:

function [a] = phase(lambda,N,H,thi

- Page 243 and 244:

Figure B.1: Picture of the surface

- Page 245 and 246:

An Omega type K thermocouple is con

- Page 247 and 248:

Figure B.2: Diagram of surface trea

- Page 249 and 250:

Figure B.3: User interface for the

- Page 251 and 252:

option when the program is started

- Page 253 and 254:

Figure B.7: Various subVIs called b

- Page 255 and 256:

Figure B.10: Program diagram for Ch

- Page 257 and 258:

The Auto program uses these same su

- Page 259 and 260:

Figure C.1: Force balance diagram f

- Page 261 and 262:

Figure C.2: Plot of cos θ vs. γlv

- Page 263 and 264:

Figure C.4: Plot of cos θ vs. γlv

- Page 265 and 266:

Equation C.8 which upon rearrangeme

- Page 267 and 268:

and electron-donor (γ - ) paramete

- Page 269 and 270:

where θ0 is the contact angle in v

- Page 271 and 272:

Kwok, et al reinforce the relation

- Page 273 and 274:

Figure C.7: Correlation between mea

- Page 275 and 276:

If one requires only an estimation

- Page 277 and 278:

32. Kwok, D.Y., et al., Langmuir, 1

- Page 279 and 280:

a separate delimited text file for

- Page 281 and 282:

2 -2 M -1 1; AreaPerTest 1.20197e+0

- Page 283 and 284:

ins1 = strcat('< ',num2str(edges(2)

- Page 285 and 286:

n(2) = n(2) + 1; case 3 n(3) = n(3)

- Page 287 and 288:

Appendix E: Estimation of Downstrea

- Page 289 and 290:

Figure E.1: Experimental FTIR appar

- Page 291 and 292:

Figure E.2: Vapor pressure apparatu

- Page 293 and 294:

Absorbance 0.16 0.14 0.12 0.1 0.08

- Page 295 and 296:

Absorbance 0.3 0.25 0.2 0.15 0.1 0.

- Page 297 and 298:

Absorbance 2.45 1.95 1.45 0.95 0.45

- Page 299 and 300:

Figure E.9: Comparison of experimen

- Page 301 and 302:

ln(Psat (Torr)) 1.5 1 0.5 0 -0.5 -1

- Page 303 and 304:

FOTS Concentration (mol/liter) 2.0E

- Page 305 and 306:

Bouwhuis, G., et al., Principles of

- Page 307 and 308:

Constantine, C., R. Westerman, and

- Page 309 and 310:

Gun'ko, V.M., et al., Inter. J. Mas

- Page 311 and 312:

Lee, L.-H., J. Coll. Int. Sci., 199

- Page 313 and 314:

Pellerite, M.J., E.J. Wood, and V.W

- Page 315 and 316:

The Aldrich Library of FT-IR Spectr

- Page 317:

VITA Todd Christopher Bailey was bo