Graco Elektr. Pumpen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

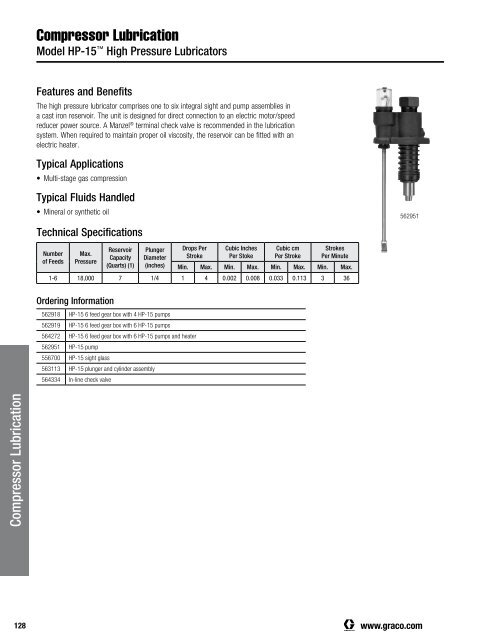

Compressor Lubrication<br />

Model HP-15 High Pressure Lubricators<br />

Features and Benefits<br />

The high pressure lubricator comprises one to six integral sight and pump assemblies in<br />

a cast iron reservoir. The unit is designed for direct connection to an electric motor/speed<br />

reducer power source. A Manzel ® terminal check valve is recommended in the lubrication<br />

system. When required to maintain proper oil viscosity, the reservoir can be fitted with an<br />

electric heater.<br />

Typical Applications<br />

• Multi-stage gas compression<br />

Typical Fluids Handled<br />

• Mineral or synthetic oil<br />

Technical Specifications<br />

562951<br />

Number<br />

of Feeds<br />

Max.<br />

Pressure<br />

Reservoir<br />

Capacity<br />

(Quarts) (1)<br />

Plunger<br />

Diameter<br />

(inches)<br />

Drops Per<br />

Stroke<br />

Cubic Inches<br />

Per Stoke<br />

Cubic cm<br />

Per Stroke<br />

Strokes<br />

Per Minute<br />

Min. Max. Min. Max. Min. Max. Min. Max.<br />

1-6 18,000 7 1/4 1 4 0.002 0.008 0.033 0.113 3 36<br />

Ordering Information<br />

562918 HP-15 6 feed gear box with 4 HP-15 pumps<br />

562919 HP-15 6 feed gear box with 6 HP-15 pumps<br />

564272 HP-15 6 feed gear box with 6 HP-15 pumps and heater<br />

562951 HP-15 pump<br />

556700 HP-15 sight glass<br />

563113 HP-15 plunger and cylinder assembly<br />

564334 In-line check valve<br />

Compressor Lubrication<br />

128<br />

www.graco.com