Graco Elektr. Pumpen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Series Progressive<br />

Manzel ® MHH Divider Valves<br />

Features and Benefits<br />

Same capable design as the Trabon MSP Series, with even tighter and more exacting<br />

tolerances. The Manzel MHH Series delivers highly accurate lube delivery for demanding highpressure<br />

grease and oil applications.<br />

• Quick change valve sections can be removed from the base assembly without disturbing<br />

any lube lines–minimizing labor cost and maximizing your machine uptime<br />

• Can be easily accessorized with magnetic and electronic proximity switch cycle indicators<br />

to provide positive assurance of a successful lube event<br />

• Alternate outlet on face of valves can be fitted with optional performance indicators, taking<br />

the guesswork out of troubleshooting<br />

• Built-in outlet check valves ensure accurate lube delivery every time<br />

Typical Applications<br />

• Compressors, industrial equipment, and where high-pressure lubrication in required<br />

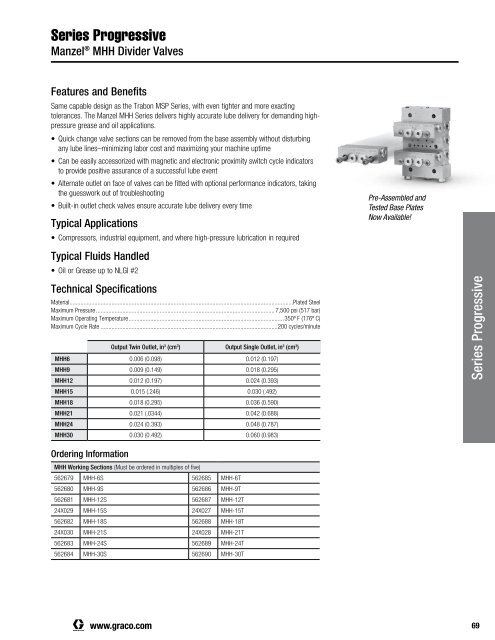

Pre-Assembled and<br />

Tested Base Plates<br />

Now Available!<br />

Typical Fluids Handled<br />

• Oil or Grease up to NLGI #2<br />

Technical Specifications<br />

Material.................................................................................................................................................Plated Steel<br />

Maximum Pressure.................................................................................................................... 7,500 psi (517 bar)<br />

Maximum Operating Temperature.....................................................................................................350º F (176º C)<br />

Maximum Cycle Rate...................................................................................................................200 cycles/minute<br />

Output Twin Outlet, in 3 (cm 3 ) Output Single Outlet, in 3 (cm 3 )<br />

MHH6 0.006 (0.098) 0.012 (0.197)<br />

MHH9 0.009 (0.149) 0.018 (0.295)<br />

MHH12 0.012 (0.197) 0.024 (0.393)<br />

MHH15 0.015 (.246) 0.030 (.492)<br />

MHH18 0.018 (0.295) 0.036 (0.590)<br />

MHH21 0.021 (.0344) 0.042 (0.688)<br />

MHH24 0.024 (0.393) 0.048 (0.787)<br />

MHH30 0.030 (0.492) 0.060 (0.983)<br />

Series Progressive<br />

Ordering Information<br />

MHH Working Sections (Must be ordered in multiples of five)<br />

562679 MHH-6S 562685 MHH-6T<br />

562680 MHH-9S 562686 MHH-9T<br />

562681 MHH-12S 562687 MHH-12T<br />

24X029 MHH-15S 24X027 MHH-15T<br />

562682 MHH-18S 562688 MHH-18T<br />

24X030 MHH-21S 24X028 MHH-21T<br />

562683 MHH-24S 562689 MHH-24T<br />

562684 MHH-30S 562690 MHH-30T<br />

www.graco.com<br />

69