Viva Brighton Issue #65 July 2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

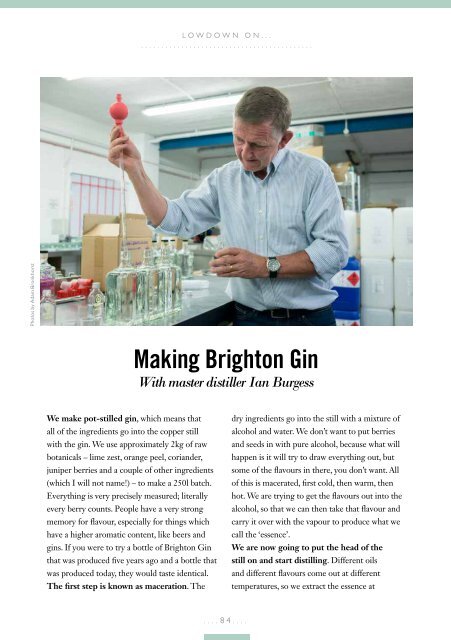

LOWDOWN ON...<br />

...........................................<br />

Photos by Adam Bronkhorst<br />

Making <strong>Brighton</strong> Gin<br />

With master distiller Ian Burgess<br />

We make pot-stilled gin, which means that<br />

all of the ingredients go into the copper still<br />

with the gin. We use approximately 2kg of raw<br />

botanicals – lime zest, orange peel, coriander,<br />

juniper berries and a couple of other ingredients<br />

(which I will not name!) – to make a 250l batch.<br />

Everything is very precisely measured; literally<br />

every berry counts. People have a very strong<br />

memory for flavour, especially for things which<br />

have a higher aromatic content, like beers and<br />

gins. If you were to try a bottle of <strong>Brighton</strong> Gin<br />

that was produced five years ago and a bottle that<br />

was produced today, they would taste identical.<br />

The first step is known as maceration. The<br />

dry ingredients go into the still with a mixture of<br />

alcohol and water. We don’t want to put berries<br />

and seeds in with pure alcohol, because what will<br />

happen is it will try to draw everything out, but<br />

some of the flavours in there, you don’t want. All<br />

of this is macerated, first cold, then warm, then<br />

hot. We are trying to get the flavours out into the<br />

alcohol, so that we can then take that flavour and<br />

carry it over with the vapour to produce what we<br />

call the ‘essence’.<br />

We are now going to put the head of the<br />

still on and start distilling. Different oils<br />

and different flavours come out at different<br />

temperatures, so we extract the essence at<br />

....84....