You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

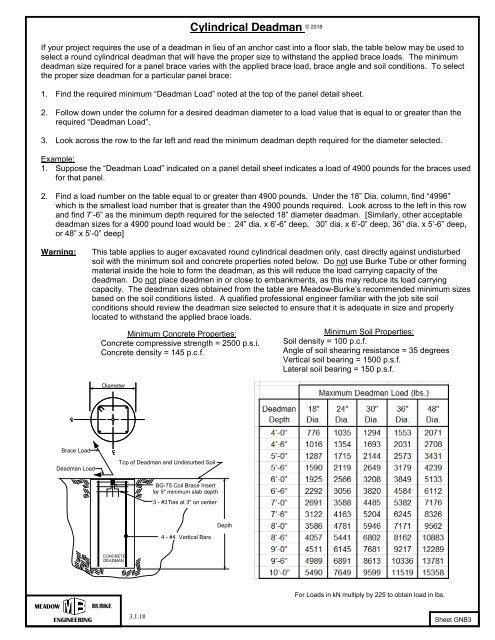

Cylindrical Deadman © 2018<br />

If your project requires the use of a deadman in lieu of an anchor cast into a floor slab, the table below may be used to<br />

select a round cylindrical deadman that will have the proper size to withstand the applied brace loads. The minimum<br />

deadman size required for a panel brace varies with the applied brace load, brace angle and soil conditions. To select<br />

the proper size deadman for a particular panel brace:<br />

1. Find the required minimum “Deadman Load” noted at the top of the panel detail sheet.<br />

2. Follow down under the column for a desired deadman diameter to a load value that is equal to or greater than the<br />

required “Deadman Load”.<br />

3. Look across the row to the far left and read the minimum deadman depth required for the diameter selected.<br />

Example:<br />

1. Suppose the “Deadman Load” indicated on a panel detail sheet indicates a load of 4900 pounds for the braces used<br />

for that panel.<br />

2. Find a load number on the table equal to or greater than 4900 pounds. Under the 18” Dia. column, find “4996”<br />

which is the smallest load number that is greater than the 4900 pounds required. Look across to the left in this row<br />

and find 7’-6” as the minimum depth required for the selected 18” diameter deadman. [Similarly, other acceptable<br />

deadman sizes for a 4900 pound load would be : 24” dia. x 6’-6” deep, 30” dia. x 6’-0” deep, 36” dia. x 5’-6” deep,<br />

or 48” x 5’-0” deep]<br />

Warning:<br />

This table applies to auger excavated round cylindrical deadmen only, cast directly against undisturbed<br />

soil with the minimum soil and concrete properties noted below. Do not use Burke Tube or other forming<br />

material inside the hole to form the deadman, as this will reduce the load carrying capacity of the<br />

deadman. Do not place deadmen in or close to embankments, as this may reduce its load carrying<br />

capacity. The deadman sizes obtained from the table are Meadow-Burke’s recommended minimum sizes<br />

based on the soil conditions listed. A qualified professional engineer familiar with the job site soil<br />

conditions should review the deadman size selected to ensure that it is adequate in size and properly<br />

located to withstand the applied brace loads.<br />

Minimum Concrete Properties:<br />

Concrete compressive strength = 2500 p.s.i.<br />

Concrete density = 145 p.c.f.<br />

Minimum Soil Properties:<br />

Soil density = 100 p.c.f.<br />

Angle of soil shearing resistance = 35 degrees<br />

Vertical soil bearing = 1500 p.s.f.<br />

Lateral soil bearing = 150 p.s.f.<br />

Diameter<br />

c L c L<br />

Brace Load<br />

c L c L<br />

Deadman Load<br />

Top of Deadman and Undisturbed Soil<br />

BG-75 Coil Brace Insert<br />

for 5" minimum slab depth<br />

3 - #3Ties at 3" on center<br />

4 - #4 Vertical Bars<br />

Depth<br />

CONCRETE<br />

DEADMAN<br />

MEADOW<br />

ENGINEERING<br />

BURKE<br />

3.1.18<br />

For Loads in kN multiply by 225 to obtain load in lbs.<br />

Sheet GNB3