You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Marina</strong><br />

www.marinaworld.com<br />

<strong>World</strong><br />

<strong>July</strong>/<strong>August</strong> <strong>2018</strong><br />

Issue 108<br />

Essential reading for marina and waterfront developers, planners and operators

WELCOME<br />

BY AIR, BY LAND AND BY SEA.<br />

LA DOLCE VITA FOR HELICOPTERS, CARS AND SUPERYACHTS<br />

In a setting surrounded by art, history and tradition, the marina in Porto Lotti offers all the magic of “la<br />

dolce vita”. SF <strong>Marina</strong> has delivered a pontoon that welcomes you no matter how you arrive, the 13 meter<br />

wide pontoon includes a helicopter landing pad, two lanes and parking for cars and superyacht facilities that<br />

welcomes yachts of all sizes.<br />

SF <strong>Marina</strong> has since 1918 been in the forefront in the field of floating breakwaters and concrete pontoons. Our worldwide installations and a century of experience<br />

and knowledge is your guarantee for a marina with the longest possible lifetime and minimum maintenance cost. Living up to our promise - still there after the storm.<br />

W W W . S F M A R I N A . C O M

<strong>Marina</strong><br />

<strong>World</strong><br />

<strong>July</strong>/<strong>August</strong> <strong>2018</strong> Vol. 18, No. 6<br />

13<br />

CONTENTS<br />

<strong>World</strong> News 6<br />

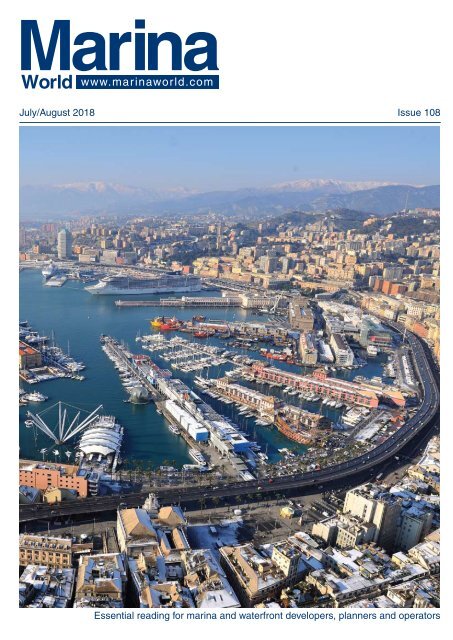

Cover Story: Genoa for Yachting 13<br />

Donatella Zucca reviews a newly formed cluster<br />

group and its aims to boost the profile of yachting<br />

in Genoa<br />

25<br />

Market Focus: Northern Russia 19<br />

St Petersburg lags behind other European<br />

coastal cities in terms of berth numbers. Is this<br />

set to change? Vladislav Vorotnikov reports<br />

Environmental Management 25<br />

EV charging at marinas; new products and<br />

programmes; pump-out at Newport Shipyard,<br />

USA<br />

35<br />

Pontoon/Dock Systems & Decking 35<br />

New products, recent projects, acquisitions and<br />

industry advice<br />

Products, Services & People 51<br />

On the cover: The Italian maritime<br />

city of Genoa offers all things<br />

nautical and is set to focus more<br />

specifically on boosting its leisure<br />

marine income. Read more on<br />

page 13. Photo: Merlo<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 3

MORE THAN MARINAS,<br />

WE DELIVER PEACE OF<br />

MIND FOR DECADES TO COME<br />

Limassol <strong>Marina</strong>, Limassol, Cyprus<br />

Camper & Nicholsons <strong>Marina</strong>s<br />

WWW.MARINETEK.NET

<strong>Marina</strong><br />

<strong>World</strong><br />

HEAD OFFICE MAILING ADDRESS &<br />

SUBSCRIPTION ENQUIRIES<br />

Loud & Clear Publishing Ltd,<br />

School Farm, School Road, Terrington St. John,<br />

Cambridgeshire PE14 7SJ, UK<br />

Editor<br />

Carol Fulford<br />

T: +44 (0) 1945 881018 F: +44 (0) 1621 855 867<br />

E: carolfulford@marinaworld.co.uk<br />

Deputy Editor<br />

Charlotte Niemiec T: +44 (0) 1945 881018<br />

E:charlotteniemiec@marinaworld.co.uk<br />

Advertisement/Commercial Director<br />

Julia Hallam<br />

T: +44 (0) 1621855 890 F: +44 (0) 1621 855867<br />

E: juliahallam@marinaworld.co.uk<br />

Administration Manager<br />

Corinna Francis T: +44 (0) 1621855 890<br />

E: corinnafrancis@marinaworld.co.uk<br />

Finance Manager<br />

Magdalena Charman T: +44 (0) 1403 733678<br />

E: accounts@marinaworld.co.uk<br />

Advertisement Production<br />

Nick Hing T: +44 (0) 1323 490384<br />

E: adstudio@marinaworld.co.uk<br />

NORTH AMERICAN OFFICE<br />

Sales Director Americas<br />

Philippe Critot<br />

PO Box 29759, Los Angeles, CA 90029-0759, USA<br />

T: +1 323 660 5459 F: +1 323 660 6030<br />

E: pcritot@marinaworld.com<br />

FRENCH OFFICE<br />

Publisher’s Representative<br />

Catherine Métais T: +33 6 60 17 75 81<br />

E: c.metais@parisrai.com<br />

ITALIAN OFFICE<br />

Advertisement Representative<br />

Ediconsult Internazionale srl<br />

piazza Fontane Marose 3, 16123 Genoa, Italy<br />

T: +39 010 583 684 F: +39 010 566 578<br />

E: genova@ediconsult.com<br />

CHINESE OFFICE<br />

Publisher’s Representative<br />

Simon Ding<br />

Bridge International Holding, Rm. 401, Building<br />

A, No. 55 Jinyu Road, Minhang District. 201103<br />

Shanghai, China<br />

T: +86 21 33231328 F: +86 21 33231366<br />

E: simon@chcbiz.com<br />

<strong>Marina</strong> <strong>World</strong> (ISSN 1471-5856) is published<br />

bi-monthly by Loud & Clear Publishing Ltd,<br />

School Farm, School Road, Terrington St.<br />

John, Cambridgeshire PE14 7SJ, United Kingdom.<br />

The <strong>2018</strong> US annual subscription price is $160.<br />

Airfreight and mailing in the USA by agent named Air<br />

Business Ltd, c/o <strong>World</strong>net Shipping Inc., 156-15 146 th<br />

Avenue, 2 nd Floor, Jamaica, NY 11434, USA.<br />

Periodicals postage paid in Jamaica NY 11431.<br />

US Postmaster: Please send address changes to<br />

MARINA WORLD, c/o <strong>World</strong>net Shipping, Inc., 156-15,<br />

146 th Avenue, 2 nd Floor, Jamaica, NY 11434, USA.<br />

Subscription records are maintained at Loud & Clear<br />

Publishing Ltd, School Farm, School Road, Terrington<br />

St. John, Cambridgeshire PE14 7SJ, United Kingdom.<br />

Air Business Ltd acts as Loud & Clear Publishing’s<br />

mailing agent.<br />

<strong>Marina</strong> <strong>World</strong> is available on subscription at the following<br />

cost:<br />

1 year (6 issues) - £80.00 Sterling ($160)<br />

2 years (12 issues) - £140.00 Sterling ($280)<br />

No part of this publication may be reproduced without<br />

the prior permission of Loud & Clear Publishing Ltd, the<br />

copyright owners. Upon application, permission may be<br />

freely granted to copy abstracts of articles on condition<br />

that a full reference to the source is given.<br />

Printed in the UK by Stephens & George<br />

© <strong>2018</strong> Loud & Clear Publishing Ltd<br />

Views expressed by individual contributors in this issue<br />

are not necessarily those of Loud & Clear Publishing<br />

Ltd. Equally, the inclusion of advertisements in this<br />

magazine does not constitute endorsement of the<br />

companies, products and services concerned by Loud &<br />

Clear Publishing Ltd. The publisher reserves the right to<br />

refuse advertising.<br />

Pioneering<br />

practices<br />

FROM THE EDITOR<br />

The ongoing fight to reduce plastic pollution in our oceans, keep our seas<br />

cleaner in general and conserve fossil fuels dominates media headlines. The<br />

marina industry continues to play its part in trying to win the battle.<br />

In the Environmental Management feature in this issue, once again we read<br />

about relatively simple measures that can be taken to improve water quality. French<br />

company CarenEcolo launches a portable slipway mat for hull cleaning that can be<br />

set up on tidal slipways and connected to a wash water filtration tank. Çeşme <strong>Marina</strong><br />

in Turkey is securing sacks of mussels around the marina for natural water filtration<br />

and natural water quality assessment. The ratio of heavy metals in the mussels will<br />

be periodically checked for an academic report.<br />

As <strong>Marina</strong> <strong>World</strong> closed for press, Abell Point <strong>Marina</strong> in Australia told us about<br />

its latest venture to be ‘plastic straw free’. If you think this seems a negligible<br />

contribution to the environment, you may think again when armed with the following<br />

statistics: over 500 million plastic straws are discarded every day globally and each<br />

straw takes up to 450 years to degrade.<br />

Responding to The Last Straw Great Barrier Reef campaign, Abell Point is now<br />

the first marina in Australia to be plastic straw free at all five of its food venues.<br />

Paper straws are provided on request and one outlet has taken a step further in<br />

selling reusable stainless straws to customers. Abell Point general manager, Kate<br />

Purdie, says “by eliminating plastic straws from our food outlets, we have eliminated<br />

70,000 straws per annum from being discarded. The marina is already plastic bag<br />

free and our participation in The Last Straw campaign is a great next step in our<br />

environmental strategy. We hope to lead the way for other marinas to follow suit and<br />

encourage all their venues to become plastic straw free.”<br />

A first for Çeşme, a first for Abell Point, and now another significant accolade<br />

for the BlueIsles Solar Microgrid Dock. Developed by US-based PowerDocks and<br />

reviewed in <strong>Marina</strong> <strong>World</strong> January/February <strong>2018</strong>, BlueIsles won the Innovation of<br />

the Year Award at the Electric & Hybrid Marine <strong>World</strong> Expo and Conference held in<br />

Amsterdam, the Netherlands, at the end of June.<br />

The product, described by one jury member as having “the potential to<br />

revolutionise the charging and docking capacity of marinas worldwide,” is a first-ofkind<br />

floating solar dock that can be positioned in remote locations or within marinas<br />

to provide in situ sustainable power. It is fully customisable in size, materials, energy<br />

generation and storage configurations.<br />

PowerDocks worked on the product in collaboration with several marina industry<br />

specialists including Bellingham Marine, ThruFlow and HyPower, and solar energy<br />

specialist Solbian. The result is pioneering, and we are delighted that it has won yet<br />

another prestigious award.<br />

Carol Fulford<br />

Editor<br />

Join the ICOMIA <strong>World</strong> <strong>Marina</strong>s Conference <strong>2018</strong> in<br />

Athens, Greece! Register today at www.worldmarinasconference.com<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 5

WORLD NEWS<br />

Family marina built<br />

to harmonise<br />

MEXICO: Poralu Marine has completed a marina at the heart of Puerto<br />

Escondido Bay in the Gulf of California for the Salcedo and Hamann families<br />

(see Sponsored Feature p. 30 & 31 for extra details).<br />

Designed to harmonise completely<br />

with its spectacular natural<br />

surroundings, the project includes<br />

private pontoons and a marina for a<br />

total of over 100 moorings.<br />

Suntex expands<br />

marinas and clubs<br />

USA: Suntex <strong>Marina</strong> Investors<br />

has further expanded its<br />

portfolio with the acquisition of<br />

Hurricane <strong>Marina</strong> on Center Hill<br />

Lake in Silver Point, Tennessee.<br />

With the change in ownership,<br />

the marina received a new 25-<br />

year lease with the United States<br />

Army Corps of Engineers.<br />

Hurricane <strong>Marina</strong> (right) has 600<br />

wet slips (48 of which were built<br />

in 2015), 40 PWC slips and 25<br />

enclosed boathouse slips. Vessels<br />

of 20 to 100ft (6 to 30m) can be<br />

accommodated.<br />

The company has also recently<br />

expanded its boat club and rental<br />

programme, announcing plans to<br />

Poralu worked in partnership with<br />

floating wave attenuator specialists<br />

Inland and Coastal <strong>Marina</strong> Systems;<br />

the first joint venture for the two<br />

companies in the Americas.<br />

Tenders<br />

in for<br />

Alimos<br />

GREECE: The directors of<br />

the Hellenic Republic Asset<br />

Development Fund (HRADF)<br />

have ruled that eight investment<br />

schemes meet the eligibility<br />

criteria for the Alimos <strong>Marina</strong><br />

tender process. Each tender will<br />

now receive Phase B (submission<br />

of binding offers) documents.<br />

Alimos <strong>Marina</strong>, situated<br />

southwest of Athens, is one of the<br />

largest marinas in Greece with<br />

1,000 berths.<br />

HRADF also confirmed that the<br />

tender process for Pylos <strong>Marina</strong><br />

in the southwestern Peloponnese<br />

is incomplete as no investment<br />

scheme submitted a binding offer.<br />

establish a new Suntex Boat Club at<br />

CrossTimbers <strong>Marina</strong>, just north of<br />

Tulsa, Oklahoma. This will be its ninth<br />

boat club location in the USA. Six new<br />

locations in northern California and<br />

Tennessee have also been secured<br />

for Suntex Watersports, the company’s<br />

boat rental programme. Club and rental<br />

fleets have been boosted by 300 new<br />

boats.<br />

Suntex now manages 46 marina<br />

properties in the USA.<br />

6<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong>

WORLD NEWS<br />

Mohammed al Mannaei, CEO P&O <strong>Marina</strong>s<br />

(seated left) and Aleco<br />

SMIP<br />

and P&O<br />

<strong>Marina</strong>s sign MoU<br />

Keusseoglou (seated<br />

right) at the signing of the<br />

agreement in Monaco.<br />

MONACO: DP <strong>World</strong> Group subsidiary P&O<br />

<strong>Marina</strong>s – manager of the Mina Rashid<br />

<strong>Marina</strong> project in Dubai – has finalised<br />

an agreement with Société Monegasque<br />

International Portuaire (SMIP) in Monaco to<br />

work on selected superyacht marina projects<br />

in the Mediterranean and around the world.<br />

A Memorandum of Understanding (MoU) was<br />

signed in Monaco in May.<br />

Mohammed Al Mannei, CEO P&O<br />

<strong>Marina</strong>s and executive director Mina Rashid,<br />

commented: “By partnering with SMIP, we will<br />

complement each other’s experience to ensure<br />

the very best facilities feature high standards<br />

and innovative services that create long term<br />

sustainable value to clients, local communities<br />

and shareholders.”<br />

Mina Rashid, a project aimed at ultimately<br />

accommodating 20,000 yachts, opened last<br />

November with the first of three phases, <strong>Marina</strong><br />

Cube. This is expected to be a new maritime<br />

tourist and entertainment hot spot stretching<br />

over 13km² (5mi²).<br />

Portland drystack<br />

opens<br />

UK: Dean & Reddyhoff has opened a new<br />

covered drystack at Portland <strong>Marina</strong> in<br />

Dorset, southwest England.<br />

Built by local contractors, the stack holds<br />

150 boats of up to 10m (33ft) in length, is 19m<br />

(62ft) high and 84m (275ft) long. The racks<br />

can be adjusted to suit different hull shapes.<br />

The structure will be clad on three sides in the<br />

autumn this year.<br />

Dean & Reddyhoff chairman, Richard<br />

Reddyhoff, commented: “The drystack was part<br />

of the original plans for Portland <strong>Marina</strong> and we<br />

are delighted that it is now built and providing<br />

secure storage for more boat owners.” The<br />

building has freed up space for additional car<br />

parking and the construction of a new boatshed.<br />

<strong>Marina</strong> <strong>World</strong><br />

partners with IBEX<br />

USA: <strong>Marina</strong> <strong>World</strong> is delighted to announce its new role as exclusive<br />

media partner for the <strong>Marina</strong> & Yard Pavilion at IBEX.<br />

IBEX (International Boatbuilders’ International Council of Marine<br />

Exhibition & Conference), the Industry Associations (ICOMIA).<br />

largest technical trade event of This aims to raise the international<br />

its kind in North America, is in its standing of IBEX by encouraging<br />

28 th year. It attracts over 7,500 and facilitating increased<br />

recreational marine industry<br />

participation by ICOMIA members<br />

professionals and boasts nearly as exhibitors, speakers and visitors.<br />

700 exhibitors. The <strong>Marina</strong> & Yard The partnership was finalised<br />

Pavilion (MYP), first introduced in June at the ICOMIA/IFBSO<br />

in 2017, will command a prime Congress, hosted in Berlin by the<br />

position at this year’s event, which International Marine Certification<br />

will be held 2 nd -4 th October in<br />

Institute (IMCI).<br />

Tampa, Florida.<br />

Expanded exhibition space,<br />

new education programmes and<br />

an increased international flavour<br />

are in the mix for the <strong>2018</strong> event<br />

including new country pavilions for<br />

South Korea, Australia, France and<br />

Italy.<br />

A further boost is assured<br />

following the signing of a<br />

collaboration agreement between<br />

IBEX co-owners – National Marine<br />

Manufacturers Association (NMMA)<br />

and RAI Amsterdam – and the<br />

In addition to touring the show<br />

and the MYP, incoming marina<br />

professionals can attend <strong>Marina</strong><br />

101 ‘Walk the Docks – First<br />

Impressions’ (a four-hour industry<br />

introduction course) and/or attend<br />

the Tampa Area <strong>Marina</strong> & Boatyard<br />

Study Tour and visit five marina<br />

facilities. Full details and costs<br />

are available from imitraining@<br />

marinaassociation.org<br />

Registration is now open for<br />

IBEX <strong>2018</strong> – find our more at<br />

www.ibexshow.com<br />

Oasis <strong>Marina</strong>s<br />

wins Wharf<br />

marinas contract<br />

USA: Oasis <strong>Marina</strong>s of Baltimore, MD, has been awarded a contract<br />

to manage all marina operations along the entire mile-long Wharf<br />

development in Washington, DC.<br />

The contract includes<br />

Market Docks, Wharf Cove,<br />

Washington Channel Moorings<br />

and the new mixed-use 200+ slip<br />

Wharf <strong>Marina</strong>, currently under<br />

construction by Bellingham<br />

Marine.<br />

“This is a huge honour,” said<br />

Dan Cowens, founder and CEO<br />

Oasis <strong>Marina</strong>s. “We have a great<br />

deal of respect for The Wharf’s<br />

development team and the<br />

vibrant community that they have<br />

created along the waterfront.<br />

At Oasis <strong>Marina</strong>s, we combine<br />

maritime expertise with hospitality<br />

experience to create a safe, fun<br />

and welcoming environment<br />

for guests. We look forward to<br />

working side by side with The<br />

Wharf as they re-establish<br />

Washington DC as a bustling<br />

waterfront city and premier<br />

destination for boaters.”<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 7

The world leader<br />

in mooring systems<br />

The marinas of the future ask for<br />

versatile systems that stand the test<br />

of time; products that can adapt to<br />

the developing demands and protect<br />

<br />

How does it work?<br />

<br />

SEAFLEX® is an elastic mooring solution that<br />

expands and retracts with each tide and<br />

wave, taking on and dampening the forces<br />

<br />

<br />

the most modern, sleek, state of the art<br />

<br />

With 45 years of research and development,<br />

SEAFLEX® is the most technologically<br />

advanced mooring option in the world,<br />

anchoring thousands of marinas, wave<br />

<br />

SEAFLEX®<br />

Rope<br />

SEAFLEX® is custom made to handle the<br />

<br />

With the system in place, the moored<br />

application is secured in all directions,<br />

throughout wind, waves and<br />

<br />

Research your options, give your marina the<br />

mooring solution it deserves!<br />

for<br />

<br />

INTERNATIONAL<br />

P +46 90 160650<br />

<br />

Contact us<br />

US & CANADA<br />

P +1 (310) 548 9100

<strong>Marina</strong><br />

focus for<br />

<strong>Marina</strong>s19<br />

AUSTRALIA: The <strong>Marina</strong>s19<br />

International Conference and Trade<br />

Exhibition will be held on the Gold<br />

Coast, Queensland 27 th -28 th May<br />

2019. The event immediately follows<br />

the Sanctuary Cove International<br />

Boat Show that flows on from the<br />

Australian Superyacht and Marine<br />

Export Conference (ASMEX).<br />

<strong>Marina</strong>s19, the next in the series that<br />

has been organised every two years<br />

since 2001 by the <strong>Marina</strong> Industries<br />

Association, will revert to a marina<br />

focused event. For the last three events,<br />

it has been run in partnership with the<br />

Boating Industries Association and has<br />

adopted a broader marine agenda.<br />

Porto Lottti joins<br />

1782 Club<br />

ITALY: Porto Lotti, the luxury 520-<br />

berth superyacht marina in the<br />

Gulf of La Spezia, has joined the<br />

exclusive Camper & Nicholsons<br />

<strong>Marina</strong>s (C&NM) 1782 Club.<br />

C&NM COO, Dan Hughes,<br />

welcomed the new club member.<br />

“We are so pleased to be closely<br />

working with Porto Lotti through<br />

the 1782 Club, which offers a<br />

unique marketing and business<br />

development platform to help<br />

promote marinas internationally,”<br />

he said. “With the recent marina<br />

extension of 14 dedicated<br />

superyacht berths now complete<br />

at Porto Lotti, larger yachts can<br />

easily be accommodated. Its unique<br />

location within the Gulf of La Spezia,<br />

provides a destination close to some<br />

of the world’s most high profile Italian<br />

shipyards and yacht manufacturers<br />

as well as being in a great location<br />

for those yachts heading south<br />

ahead of the season.”<br />

In addition to the 14 superyacht<br />

berths, the marina also boasts a<br />

transit berth for yachts up to 180m<br />

(590ft); one of very few in the region.<br />

Lakeland Leisure buys<br />

Roydon <strong>Marina</strong><br />

UK: Windermere-based Lakeland Leisure Estates has purchased Roydon<br />

<strong>Marina</strong> Village, a 56-acre inland marina and leisure complex in Essex. The site<br />

includes a 350-berth marina, 60 holiday lodges and a hotel.<br />

Nigel Wimpenny, managing director<br />

of Lakeland Leisure Estates, said:<br />

“This excellent site is a key part of our<br />

strategy to grow our business portfolio,<br />

mainly through the acquisition of wellestablished<br />

locations.”<br />

Lakeland owns and manages a<br />

WORLD NEWS<br />

variety of leisure complexes including<br />

five marinas. In January this year it<br />

acquired Deganwy <strong>Marina</strong>, North<br />

Wales, from the Crown Estate. The<br />

acquisitions of the Roydon and<br />

Deganwy properties were made using<br />

HSBC funding packages.<br />

Milestone achievement at<br />

Ocean Village<br />

UK: The refurbishment and extension of MDL’s Ocean Village <strong>Marina</strong> in<br />

Southampton has reached a milestone. Walcon Marine has completed Piers A<br />

to D, which are now in use, and has three more to finish.<br />

All walkways, piers and pontoons<br />

have been constructed using Walcon’s<br />

System 21 product and heavy-duty<br />

wave-attenuating pontoons have<br />

been used near the marina entrance.<br />

Pontoons have been decked with<br />

a charcoal grey composite product<br />

supplied by Dura Composites (see p.<br />

46).<br />

A key feature of the new layout is the<br />

introduction of Pier P (for Platinum). For<br />

higher fee paying customers, Walcon<br />

has designed and built customised<br />

high-spec pontoons with under-deck<br />

services, branded cleats and smart<br />

services using keypads and mobiles.<br />

The berthing package includes extra<br />

shoreside services and privileges.<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 9

• SERVICE PEDESTALS<br />

• SANITATION PUMP-OUTS<br />

• EMERGENCY SERVICES<br />

• ELECTRIC VEHICLE CHARGING<br />

• LIGHTING<br />

• PRE-PAYMENT SYSTEMS<br />

• SMART METERING<br />

• ELECTRICAL DISTRIBUTION<br />

• ACCESSORIES<br />

• INSTALLATION<br />

• TESTING & INSPECTION<br />

<strong>Marina</strong> Solutions<br />

by<br />

THE WORLD’S LEADING SPECIALIST<br />

Serving the <strong>Marina</strong> Industry since 1990<br />

S<br />

Over 25 Years’<br />

Experience<br />

Manufactured<br />

in the UK<br />

SMART<br />

Integration<br />

LED Amenity<br />

Lighting<br />

Internal Electric &<br />

Water Segregation<br />

Bespoke<br />

Manufacturing<br />

CE<br />

Certified<br />

t: +44 (0) 1205 724754<br />

@Rolec<strong>Marina</strong><br />

e: rolec@rolecserv.co.uk www.rolecserv.com

<strong>Marina</strong> Agana - the<br />

100th project for<br />

Marinetek Adriatic<br />

CROATIA: Marinetek NCP, now renamed Marinetek Adriatic, has<br />

completed a full re-build of <strong>Marina</strong> Agana, its 100th project to date.<br />

Situated halfway between Split<br />

and Sibenik in a sheltered bay in the<br />

picturesque village of <strong>Marina</strong>, <strong>Marina</strong><br />

Agana offers boaters a safe and<br />

peaceful base from which to explore the<br />

island-studded Dalmatian Coast.<br />

Marinetek replaced all existing<br />

pontoons, cleats, fenders and<br />

access bridges. The completed<br />

marina has six piers and offers 134<br />

berths for vessels up to 25m (82ft).<br />

Marinetek also installed completely<br />

new infrastructure for shoreside and<br />

pontoon power and water, and all<br />

WORLD NEWS<br />

berths have new service pedestals. The<br />

result, says Marinetek Adriatic director<br />

Boris Miškić, is to make <strong>Marina</strong> Agana<br />

“one of the best equipped and most<br />

modern marinas on the coast.”<br />

Green court gives<br />

green light for<br />

Kennedy Point<br />

NEW ZEALAND: Plans for Kennedy<br />

Point Boatharbour at Kennedy<br />

Bay, Waiheke Island, were upheld<br />

when the developers won their<br />

case against local opposition at<br />

the Environment Court in May. The<br />

marina was approved by Auckland<br />

Council back in May 2017.<br />

Final design work on the 186-berth<br />

marina will be complete in a few<br />

months’ time and marketing and sale<br />

of berths, ranging in length from 10 to<br />

25m (33 to 82ft), will start immediately.<br />

Redeveloping<br />

Harbour Island<br />

BAHAMAS: The Government of<br />

the Bahamas has signed a Heads<br />

of Agreement with 4M Harbour<br />

Island for the redevelopment<br />

of Harbour Island <strong>Marina</strong> in<br />

Eleuthera.<br />

The US$45 million project,<br />

scheduled to be completed in two<br />

and a half years, will feature a<br />

55-slip megayacht marina, wide<br />

ranging leisure amenities, retail and<br />

residential property.<br />

Rebuilt marina puts<br />

community first<br />

AUSTRALIA: Elizabeth Bay <strong>Marina</strong>, Sydney, has been rebuilt by Bellingham<br />

Marine Australia. The company worked with New South Wales authorities to<br />

develop a new layout that would offer a safer, modern marina whilst allaying<br />

concerns from local residents about over-development.<br />

“We wanted to make sure that the<br />

final design would have public approval,<br />

as this is a community marina,” said<br />

John Spragg, general manager<br />

Bellingham Marine Australia. “It was<br />

important that the new design not<br />

significantly alter the waterfront or the<br />

lifestyle of the surrounding community.”<br />

The new marina has an extra 13<br />

berths for boats of 12 to 15m (39 to 49ft)<br />

and a launching pontoon for kayaks and<br />

paddleboards. In an effort to encourage<br />

growth of seagrass, the launch area<br />

has been decked with a grated material<br />

- long used by Bellingham Marine for<br />

projects in the USA - that allows light to<br />

penetrate the water.<br />

Elizabeth Bay <strong>Marina</strong> also has 47<br />

swing moorings and is protected by a<br />

4m (13ft) wide skirted wave attenuator.<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 11

Floating pontoons<br />

Steel: strength and versatility<br />

Made in Italy<br />

Pontoons, breakwaters, piers for super<br />

yachts, floating bridges and constructions:<br />

the best solutions for connecting sea and<br />

land by means of strong and reliable<br />

structures, in aluminium, concrete or steel,<br />

standard or tailor made.<br />

Khiran - Kuwait: 3,350 m of pontoons and fingers for Khiran <strong>Marina</strong> in the Arabian Gulf<br />

Let’s shape together<br />

your new marina<br />

Tel. +39 0422 702412<br />

info@ingemar.it<br />

www.ingemar.it<br />

Pontoons and constructions over the water

COVER STORY<br />

<strong>Marina</strong> Porto Antico (left) and <strong>Marina</strong><br />

Molo Vecchio, two of Genoa’s key<br />

marinas. Photo: Merlo<br />

Cluster group boosts<br />

Genoa’s yachting<br />

profile<br />

The maritime city of Genoa began a specific journey into the yachting<br />

sector many years ago. This move has now been further accelerated by the<br />

development of the ‘Genoa for Yachting’ cluster group and the efforts of Italian<br />

shipyard Amico & Co. Donatella Zucca reports<br />

In November 2017, the Genoa for<br />

Yachting cluster was formed by a group<br />

of 27 professional boating companies<br />

to add a new dimension to the historic<br />

naval and seafaring traditions of the<br />

Ligurian capital. The aim of the group –<br />

to establish yachting as a strategic part<br />

of the city’s economy – is influenced<br />

by its popularity with nautical tourists<br />

and its superyacht potential. For around<br />

eight months a year, the city hosts<br />

around 290,000 boating visitors and an<br />

average of 1,200 crew members. The<br />

city has several important shipyards<br />

and three key marinas, two of which<br />

have berthing for yachts over 100m<br />

(328ft) in length.<br />

Some background to Genoa’s<br />

yachting provenance is important, and<br />

the best overview comes with the Duca<br />

degli Abruzzi Porticciolo. This is the<br />

oldest tourist port in Italy and is host<br />

to established clubs like the Genoese<br />

Rowing Club (1890), Elpis Genoese<br />

Canottieri (1902), Italian Naval League<br />

Genoa Centre (1900), Unione Dilettanti<br />

Pesca (1928) and the Italian Yacht<br />

Club (1879) – the oldest sailing club<br />

in the Mediterranean.<br />

Genoa for Yachting<br />

With 680 direct employees, over<br />

1,000 suppliers, 360,000m²<br />

(430,556yd²) of port area, a<br />

turnover of about €100 million and a<br />

supply chain value of €330 million,<br />

the companies of newly founded<br />

Genoa for Yachting have a notable<br />

and ever increasing impact on the<br />

city. This is further enhanced by the<br />

local presence and role of the Italian<br />

Naval Register RINA, founded<br />

in Genoa and actively involved<br />

in classification, certification,<br />

inspection and testing services, and the<br />

Genoa International Boat Show.<br />

One of the top boat shows in Europe<br />

until the economic downturn lashed out<br />

at Italy’s yachting market, the Genoa<br />

show continues as a greatly reduced<br />

but nonetheless important showcase for<br />

the small and medium sized companies<br />

that are crucial to the Italian leisure<br />

marine sector. Despite the success of<br />

Fiera Milano’s Versilia Yachting Rendez<br />

Vous in Viareggio, the Genoa Boat<br />

Show remains a true national icon.<br />

Leading the Genoa promotion<br />

The Genoese and Mediterranean<br />

boating scene also owes much to<br />

Amico & Co, a family-run refit and<br />

service yard that competes well with<br />

leading firms on the French and<br />

Spanish coasts. Founded 25 years<br />

Amico’s covered air-conditioned<br />

dock is a very recent investment.<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 13

COVER STORY<br />

Left & below: The Amico dock and<br />

quayside facilities are perfectly positioned<br />

close to Genoa city centre.<br />

ago, Amico is now at the top end of<br />

the industry with up to 110 orders per<br />

year. The company has a network<br />

of 650 suppliers, partnerships with<br />

specialist companies, and promotes a<br />

comprehensive plan to compete with La<br />

Genoa for Yachting<br />

participants<br />

Services:<br />

Amico Servizi Srl<br />

Femobunker Srl<br />

Genoa Sea Service Srl<br />

Molo Vecchio Marine Supplies Srl<br />

Molo Vecchio Crociere Srl<br />

Pesto Sea Group Srl<br />

San Giorgio Shipping Services Srl<br />

SCS Ship & Crew Services Srl<br />

Yachtline Arredomare 1618 Spa<br />

<strong>Marina</strong>s:<br />

<strong>Marina</strong> Genova Srl<br />

<strong>Marina</strong> Molo Vecchio Srl<br />

<strong>Marina</strong> Porto Antico Spa<br />

Shipbuilding:<br />

Amico & Co Srl<br />

Cantieri Navali Di Sestri Srl<br />

Cantieri Navali Genovesi Srl<br />

Gatti Srl, Genoa Sea Service Srl<br />

Consorzio Assistenza Nautica<br />

Technology:<br />

AB Volt Srl<br />

Acier Steel Srl<br />

Cn Sat Srl<br />

Cooperativa Steel Works<br />

Interni Navali Genovesi Srl<br />

Lisi Arredamenti Srl<br />

Motonautica Sorin Diesel Sas<br />

Schembri E Gardella Verniciatura<br />

Yacht<br />

Tecnomarine Srl<br />

Viacava Srl<br />

Ciotat in Bouches du Rhône (France)<br />

and Mb92 in Barcelona (Spain).<br />

Amico’s Genoa project involves<br />

the development of a refit and repair<br />

district equipped with new shipbuilding<br />

infrastructure, mooring facilities and<br />

services, and a rejuvenation of the<br />

city’s waterfront in liaison with local<br />

adminstrations. The journey, started<br />

some years ago by president Alberto<br />

Amico who was acting in part on his<br />

father’s thought processes, has led to<br />

continuous growth of the Amico yard.<br />

The most recent advance, prior to the<br />

formation of Genoa for Yachting, was<br />

the unauguration in 2016 of a 102m<br />

(335ft) long covered and air-conditioned<br />

dock and an upgrade of electrical<br />

installations.<br />

With its facilities in Genoa and Loano<br />

(Amico Loano), the group operates<br />

on various levels for yachts from 30 to<br />

140m (98 to 459ft) and has spent years<br />

consolidating its position and investing<br />

in its facilities. Up to €55 million is in the<br />

process of being spent in total at the<br />

Genoa yard.<br />

Mooring up near the city<br />

Genoa has several key marinas<br />

including <strong>Marina</strong> Genova, <strong>Marina</strong> Porto<br />

Antico and <strong>Marina</strong> Molo Vecchio.<br />

<strong>Marina</strong> Genova is an excellent<br />

nautical hub and one of four<br />

Mediterranean marinas able to<br />

accommodate megayachts up to 130m<br />

(426ft) in length. It offers a high level<br />

of dedicated services meeting the<br />

needs of both shipowners and crew.<br />

The marina has 500 berths, 100 of<br />

which are reserved for superyachts,<br />

the largest refuelling docks in the<br />

Mediterranean and a dedicated build<br />

and repair area. To complement<br />

restaurants, hotels and commercial<br />

activities, there are various initiatives for<br />

shipowners, guests and crew. We Love<br />

Crew offers social events.<br />

Located to the west of Genoa city<br />

centre and close to the international<br />

airport, <strong>Marina</strong> Genova sits amidst an<br />

area that is historically associated with<br />

large vessels and shipbuilding. The<br />

future seems bright. “The <strong>2018</strong> season<br />

will surely confirm growth following the<br />

positive signs experienced by Italian<br />

marinas last year,” says Giuseppe<br />

Pappalardo, CEO of <strong>Marina</strong> Genova<br />

management company SSP Società<br />

14<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong>

COVER STORY<br />

Talking to Alberto Amico<br />

Q: The goal<br />

of Genoa for<br />

Yachting is to<br />

create a yachting<br />

hub supported<br />

by facilities<br />

comparable with<br />

Mb92 and La Alberto Amico<br />

Ciotat. Why Genoa?<br />

A: Genoa has the potential to become<br />

a hub of excellence. The location and<br />

climate are ideal and the city is a fair<br />

size with quality services and beautiful<br />

cultural and touristic offerings. Our<br />

port infrastructure generates a good<br />

reception and we have the right growth<br />

potential, even in the megayacht<br />

sector. In terms of shipbuilding, there<br />

are not only yards like Amico but a<br />

whole chain of specialist companies<br />

dedicated to pleasure craft and<br />

large yachts. The creation of Genoa<br />

for Yachting has prompted greater<br />

awareness of the current importance<br />

of the nautical sector for the city and its<br />

further potential.<br />

Q: How are discussions progressing?<br />

A: A constructive dialogue has been<br />

started with the president of the<br />

region, Giovanni Toti, the mayor,<br />

Marco Bucci, and the president of the<br />

port system authority, Paolo Emilio<br />

Signorini, on the strategy for economic<br />

development and the port system in<br />

coming years. The large yacht sector<br />

will be a protagonist in this, which is a<br />

fundamental change of direction.<br />

Q: What is Amico’s current role and<br />

the main focus of your side of the<br />

project?<br />

A: We are the promoter of the Genoa<br />

for Yachting working group. Our project<br />

is divided into three phases, one of<br />

which is shipbuilding infrastructure.<br />

This mainly comprises a new 4,000<br />

ton ship lift, new reception mooring<br />

capacity for yachts of 45 to 110m (148<br />

to 361ft) and more space for crews<br />

and ground services.<br />

Q: Will the ‘Blueprint’ designs of<br />

renowned architect Renzo Piano be<br />

part of the Genoa waterfront project?<br />

A: Mayor Bucci is pushing for swift<br />

construction of the new waterfront<br />

and all planning and planning<br />

procedures have started. They are in<br />

total harmony with Renzo Piano. The<br />

new waterfront is a beautiful project,<br />

it is achieveable, and the big yachts<br />

will be one of the drivers of economic<br />

development in the sector.<br />

Genoa by night (above) and by day at<br />

<strong>Marina</strong> Genova (below) conveniently close<br />

to the airport.<br />

Sviluppo Porti. “Our infrastructure,<br />

as well as our strategic location,<br />

enables us to give attentive service to<br />

large vessels that are often on hectic<br />

schedules and presents opportunities<br />

for tourists to discover the treasures<br />

and culture of Genoa,” he adds.<br />

At the centre of the city waterfront<br />

lies <strong>Marina</strong> Porto Antico, a haven<br />

largely for small and medium sized<br />

boats. Berth holders at its 270 berths<br />

can take advantage of WiFi, electric<br />

dock carts, laundries, supermarket,<br />

shops, hotels and restaurants. Over<br />

the past two years, following the Italian<br />

crisis that resulted in a significant<br />

exodus of boats, occupancy has started<br />

to rise and many previous customers<br />

have returned. These are primarily from<br />

northern Italy with some from Genoa<br />

itself. Around a third of the berths for<br />

boats of 20m (66ft) and above are<br />

leased by foreigners. All customers<br />

appreciate being so close to the<br />

amenities of the city centre.<br />

<strong>Marina</strong> Molo Vecchio (MMV) also<br />

enjoys a prime waterfront location on<br />

the 450m (1,476ft) long Molo Vecchio<br />

close to the famous aquarium. The<br />

marina offers 160 berths for vessels<br />

of 22 to 90m (72 to 295ft) at stern-to<br />

moorings, has a 150m (492ft) alongside<br />

berth, and an additional 100 berths<br />

for boats of 5 to 18m (16 to 59ft).<br />

These are offered at competitive rates<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 15

COVER STORY<br />

Awards and agreements<br />

<strong>Marina</strong> Genova was awarded<br />

RINA MaRINA Excellence<br />

certification in May. It achieved<br />

maximum score due to its deep<br />

waters, quality services and<br />

special facilities for superyachts.<br />

CEO Giuseppe Pappalardo<br />

commented: “We are very proud<br />

of this certification, which<br />

represents an important goal,<br />

and helps us to keep pursuing<br />

excellence.”<br />

The award arrived at the<br />

same time as an agreement was<br />

reached between <strong>Marina</strong> Genova<br />

and <strong>Marina</strong> di Portofino to jointly<br />

promote international yacht tourism<br />

in Liguria. From now on, <strong>Marina</strong><br />

Genova will offer yachts waiting<br />

for a Portofino mooring slot (22nm<br />

away) essential stop-over services.<br />

<strong>Marina</strong> di Portofino is one of<br />

the most famous and luxurious<br />

harbours in the world, set in the<br />

middle of Portofino Bay. It offers 17<br />

berths for yachts of 10 to 80m (33<br />

to 262ft).<br />

<strong>Marina</strong> Genova is one of four Mediterranean marinas able to accommodate megayachts up<br />

to 130m (426ft) in length. One hundred of its 500 berths are reserved for superyachts.<br />

Photo: Merlo<br />

especially for long-term contracts.<br />

Customers mooring up at the marina<br />

enjoy year-round service and the fee<br />

includes private parking along the<br />

Molo Vecchio. Crews enjoy discounts<br />

at nearby apartments and MMV office<br />

staff provide information on activities,<br />

events, games, barbecues etc., that<br />

take place on the pier. Since 2001 the<br />

marina has hosted the annual MYBA<br />

Charter Show, which is dedicated to<br />

luxury yacht charter.<br />

Martini <strong>Marina</strong>s floating pontoons.<br />

The best, from all points of the compass.<br />

SWITZERLAND<br />

CROATIA<br />

GREECE<br />

NETHERLANDS/BELGIUM<br />

ROMANIA<br />

T. +41 91 9945545<br />

T. +385 01 6530040<br />

T. +30 23 10692899<br />

T. +31 6 46140603<br />

T. +40 341 482664<br />

info@interbox.ch<br />

stp@stp-croatia.com<br />

makis@zaggas-group.gr<br />

info@aquamore.info<br />

office@opalconstruct.ro<br />

Martini Alfredo S.p.A.<br />

Via Centro Industriale Europeo, 43<br />

P.O. Box 30 - 22078 Turate (CO) - Italy<br />

Tel +39 02 963941 - Fax +39 02 9682613<br />

marinas.export@martinialfredo.it<br />

www.martinialfredo.it<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 17

Seawork

MARKET FOCUS: NORTHERN RUSSIA<br />

The extensive Imperatorsky Yacht Club in St<br />

Petersburg has modern infrastructure and<br />

generous water space.<br />

Highs and lows in<br />

St Petersburg<br />

After several years of uncertainty, marinas in St Petersburg reported recordbreaking<br />

occupancy and profitability in 2017. The Russian north-west coast<br />

now clearly lacks berths and this may push investors to pump money into new<br />

projects. Vladislav Vorotnikov reports<br />

St Petersburg is commonly known<br />

in Russia as its national sea capital.<br />

It is the most popular destination for<br />

yachtsmen in European Russia but,<br />

over the past few years, the local<br />

marinas have faced a tough challenge:<br />

the land they occupy appears to be<br />

more valuable than their business.<br />

“Ten marinas in St Petersburg have<br />

been sold off and closed during the<br />

past five years,” said Alexander Uralov,<br />

spokesman for St Petersburg City Hall.<br />

The new owners have built premium<br />

cottages and hotels on the land. As a<br />

result, the total number of berths in St<br />

Petersburg shrunk from 3,222 in 2012<br />

to around 2,700 in 2017, according to<br />

Uralov, even though some new marinas<br />

have opened in the city during this<br />

period.<br />

There has, however, been a clear<br />

upward trend in the market since<br />

2016. The occupancy of an average<br />

marina in St Petersburg reached an<br />

unprecedented 90% during the last<br />

season, with more local residents<br />

starting to buy yachts and more<br />

foreigners coming in from Europe.<br />

“In the 2017 season the demand was<br />

15 to 20% higher than in the previous<br />

year, when we already had occupancy<br />

ranging from 86 to 89% for most of the<br />

year,” said Oleg Virolainen, chairman of<br />

the board of the Vostochnyi Yacht Club.<br />

“Because of this, the club invested<br />

money last season to expand the<br />

marina, adding 36 new berths.”<br />

It is believed that the shortage of<br />

berths will become even more apparent<br />

over the next few years but this may still<br />

not make for a perfect environment for<br />

investment.<br />

Still not Stockholm<br />

When it comes to the development of<br />

yachting, St Petersburg still lags behind<br />

other major cities in northern Europe.<br />

While Stockholm attracts on average<br />

24,000 yachts per year and Helsinki an<br />

annual figure of 19,000, St Petersburg<br />

records just 6,000 according to<br />

estimates from the All-Russian Yachting<br />

Sport Association.<br />

There are infrastructure problems<br />

on the Russian north-west coast that<br />

hamper the development of yachting,<br />

including the lack of marinas on the<br />

route from Europe to St Petersburg.<br />

“European yachtsmen refrain from<br />

visiting St Petersburg because on the<br />

sea routes in [the north-west of] Russia<br />

there are no berths where one could<br />

wait out a storm,” commented Vladimir<br />

Silkin, chairman of the Yachting Sport<br />

Association.<br />

In addition, there is hardly any winter<br />

Konstantin Fort is a 160-berth<br />

marina with customs clearance.<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 19

THE WORLD’S LARGEST<br />

MARINE EQUIPMENT TRADE SHOW<br />

The METSTRADE Show is the world’s largest marine equipment trade show<br />

and the only truly international B2B exhibition for the marine leisure industry.<br />

The <strong>Marina</strong> & Yard Pavilion, one of the three specialised pavilions of<br />

METSTRADE, brings together the world’s largest concentration of exhibitors<br />

from the marina & yard industry. It has become the first port of call for marina<br />

professionals from around the world.<br />

13 - 14 - 15<br />

November <strong>2018</strong><br />

RAI Amsterdam<br />

The Netherlands<br />

METSTRADE FEATURES<br />

ORGANISED BY POWERED BY MEMBER OF<br />

OFFICIAL<br />

METSTRADE<br />

MAGAZINE<br />

OFFICIAL<br />

SYP<br />

MAGAZINE<br />

OFFICIAL<br />

MYP<br />

MAGAZINE

MARKET FOCUS: NORTHERN RUSSIA<br />

mooring in St Petersburg so most boats<br />

from the city are transferred to Helsinki<br />

for the winter season. The local marina<br />

industry constantly loses money as a<br />

result.<br />

“By having 24,000 berths, like, for<br />

example, Tallinn, St Petersburg could<br />

earn around €144 million per year. This<br />

is the amount the city is losing by not<br />

taking steps to promote the development<br />

of its marinas,” commented Sergey<br />

Kovaliev, director of the local consulting<br />

agency Interconsult LLC.<br />

In north-west Russia it costs €3.5<br />

million to build a marina with 200 berths,<br />

not taking into account the spend on<br />

building a fuel station and certain other<br />

costs. The payback on this investment in<br />

St Petersburg now takes 14 years, given<br />

the average profitability in the business<br />

over the last few years, according to<br />

Interconsult LLC estimates. This is too<br />

long a period of time and scares away<br />

potential investors.<br />

“In many countries, marinas<br />

are being built by public-private<br />

partnerships with state funding,” noted<br />

Vladimir Lubomirov, manager of St<br />

Petersburg Yacht Club. “This approach<br />

has proved its value, but it has not been<br />

used by the Russian authorities as yet.”<br />

“In theory, to give strong impetus<br />

for the development of the marina<br />

industry, three or four marinas should<br />

be constructed between the European<br />

border and St Petersburg as it takes 24<br />

hours for an average yacht to cover the<br />

distance between the nearest marina in<br />

Finland and the city,” explained Andrey<br />

Lapko, an analyst with the Russian<br />

Tourism Academy.<br />

Building marinas by public-private<br />

partnership is quite possible but the<br />

main obstacle is that federal and<br />

regional authorities have first to agree<br />

on the projects among themselves. In<br />

Russian legislation, the water body<br />

belongs to the federal authorities but<br />

yachting taxes are claimed by the<br />

regional authorities. The different<br />

agencies must join forces to work this<br />

out and, in Russia, this could be quite<br />

an issue.<br />

Trying to fill the gaps<br />

Nevertheless, the authorities in Russia<br />

really seem to care about turning St<br />

Petersburg into the new centre of sea<br />

tourism, including yachting. Certain<br />

steps have been taken towards<br />

this, including opening a customs<br />

From the air: St Petersburg marinas enjoyed an unprecedented 90% occupancy last season.<br />

Imperatorsky Yacht Club is owned by Burevestnik Group. The company also owns marinas in<br />

Sochi and Moscow.<br />

clearance point at the Russian yacht<br />

club Konstantin Fort. This is a new<br />

experiment for Russia and could be<br />

expanded.<br />

Konstantin Fort is located 85<br />

miles away from the Russian border<br />

with Finland and there are six other<br />

marinas in between. A boat owner from<br />

Europe must pass customs clearance<br />

somewhere before visiting any of them.<br />

“We have a marina for 160 yachts<br />

and the entire customs clearance in<br />

Konstantin Fort takes from 40 to 60<br />

minutes,” development director Kiryll<br />

Razumov confirmed. Other established<br />

clearance points may or may not be<br />

operating as efficiently. “It is hard to<br />

say whether the main customs point<br />

for private boats located in Vyborg is<br />

operating properly or not. Officially, it<br />

is, but I’ve heard there were certain<br />

difficulties for some boats from Finland<br />

to undergo custom clearance there.<br />

Boat owners from Finland know this<br />

and, thanks to them, everyone else<br />

knows,” Razumov stressed.<br />

In addition to the problem with the<br />

customs clearance, there are also<br />

certain bureaucratic issues that hold<br />

up marina development. “There are<br />

certain gaps in legislation that brought<br />

us numerous problems when we were<br />

building coastal protection infrastructure<br />

for our marina,” commented Tatiana<br />

Ryazanova, spokeswoman for the<br />

Vostochny Yacht Club. “There are<br />

several different legal codes that<br />

regulate what permissions are required<br />

to do what. However, these regulations<br />

provide no information on what<br />

documents must be submitted to the<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 21

Single or Multi-site<br />

enterprise solution<br />

Advanced contact<br />

relationship management<br />

Deferred revenue and<br />

forecast analysis<br />

Berthing efficiency and<br />

occupancy reporting<br />

Deep integration to numerous<br />

accounting packages<br />

GDPR compliant tools to<br />

support your business needs<br />

Modules Include:<br />

Synchronisation with Microsoft Dynamics CRM, Integrated Website Bookings,<br />

Boat Yard Manager, Integrated EPoS, Pedestal integrations to Rolec and Meter-MACS,<br />

Dockside Manager, Direct Debit Management<br />

Call: +44 (0) 1953 608001<br />

Email: sales@havenstar.com<br />

www.havenstar.com<br />

WWW.JONASSOFTWARE.COM<br />

SOFTWARE TM<br />

PB3932 Star <strong>Marina</strong> Solutions advertising in <strong>Marina</strong> <strong>World</strong> <strong>July</strong>/<strong>August</strong> <strong>2018</strong> issue ARTWORK.indd 1 26/06/<strong>2018</strong> 11:57

MARKET FOCUS: NORTHERN RUSSIA<br />

federal agencies so it is extremely hard<br />

to certify the land to build a marina.”<br />

Berthing costs are another factor. It<br />

costs Rub1,800 (€25) to occupy a 9m<br />

(29ft) long berth for 24 hours. For a<br />

boat of 9 to 30m (29 to 98ft), the cost<br />

is Rub3,600 (€45), confirmed Kiryll<br />

Razumov. In general, The Russian<br />

Gazette, the official publication of the<br />

Russian federal government, asserts<br />

that St Petersburg’s marinas offer<br />

services at higher prices than European<br />

marinas. The Russian Gazette reports<br />

that, on average, it costs €50 to rent<br />

a berth in St Petersburg for 24 hours;<br />

nearly twice as much as in Helsinki,<br />

Tallinn or Stockholm, where the prices<br />

range from €22 to 27.<br />

New projects<br />

Although old problems are yet to<br />

be solved, the marina industry in St<br />

Petersburg continues to develop and<br />

there are several potential projects in<br />

the pipeline.<br />

Russian gas giant Gazprom has<br />

recently started building a major yacht<br />

club in the city with a marina designed<br />

for 200 boats. The investment cost<br />

of the project is $60 million and it is<br />

Despite the availability of berths for large boats, St Petersburg lags behind other European<br />

‘sea capitals’ in terms of overall berth numbers.<br />

believed that the yacht club will occupy<br />

an area of around 3,600ha (8,896<br />

acres). Gazprom plans to make its new<br />

facility operational by 2020.<br />

A similar project is pledged for<br />

Kroonstad Island, where a yacht<br />

club with a marina for 100 boats is<br />

expected to be built by a group of<br />

private investors. The details of this<br />

project remain secret as yet but it is<br />

believed that the marina should be<br />

completed by 2021. The price tag of<br />

the project is estimated at Rub1 billion<br />

($18 million).<br />

There have also been reports on<br />

several other new marina projects in<br />

St Petersburg and Leningrad Oblast,<br />

including some that involve non-<br />

Russian investors. Several marinas<br />

are touted with a total of 500 berths.<br />

However, none of the projects has been<br />

officially confirmed.<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 23

Hazelett<br />

Marine<br />

Conservation Elastic<br />

Mooring Systems<br />

For Yachts and Docks<br />

AUCTION<br />

BUSINESS CLOSING<br />

1020 E Broad Street, Elyria, Ohio<br />

Tuesday <strong>July</strong> 31st 10:00 AM<br />

Boat Lifts/Autos/Trailers/Mower:<br />

‘08 Con-O-Lift 35k cap, ‘00 Con-O-Lift, Ford<br />

F-450xl Super Duty Dsl , Chevy Silverado<br />

2500HD Ext-Cab, Dodge 2500 Sprinter Truck,<br />

Yellow Yard Tractor Eagle II, Alum Storm<br />

Box Trailer, Chevy 2500 HD 4x4 w/<br />

Meyer Plow, Lift-All Boat Lift, Boat Dri-<br />

Lift, 2 Gray Marine V-8 Engines, Simplicity<br />

0-turn mower, Boat: 300 boat stands,<br />

11 boat dollies, 7 boat jacks, Samsel<br />

straps, anchors, props.<br />

TERMS: Cash/check/Visa/MC b4<br />

remove w/proper I.D., 3% buy fee,<br />

3% ref 4 cash, Prev 1 hr b4.<br />

Please Titan follow Deck the is engineered link below to for be full<br />

the last decking you’ll ever<br />

auction use. details. Made of UV-protected 100% polypropylene, it won’t rot,<br />

warp, dent, splinter or bend and will never need painting or<br />

First staining Quality<br />

– perfect for commercial docks and piers of any size!<br />

All Titan Decking is backed by a 12 year limited warranty.<br />

Auction & Realty<br />

Mark Walton, Auctioneer -<br />

Mark Abood, Apprentice<br />

330-607-3687<br />

Titan Classic Titan X-Series Titan Open-X Series<br />

waltonauctionsite.com/upcoming<br />

TitanDeck.net | 877-207-4136<br />

Dry-Stack Storage Machinery<br />

Semi-automated<br />

equipment for<br />

drystacks<br />

Boat delivery: less<br />

than 3 minutes<br />

Better effi ciency<br />

per square meter<br />

www.hazelettmarine.com<br />

15 135 Palmer West Lakeshore Court Suite Drive, 212 A<br />

PO Box 600<br />

South Colchester, Burlington,<br />

Vermont 05446-0600<br />

Vermont, EMAIL: info@hazelettmarine.com<br />

05403<br />

Office: TELEPHONE: 802 (802) 399 2627<br />

863-6376<br />

Email: FAX: (802) info@hazelettmarine.com<br />

863-1523<br />

WORLDWIDE<br />

PROJECTS<br />

Ask for dealer contact<br />

in your country<br />

www.domingocapria.com info@domingocapria.com

Is your marina ready<br />

for EV customers?<br />

ENVIRONMENTAL MANAGEMENT<br />

Recent figures published by the UK Society of Motor Manufacturers and<br />

Traders (SMMT) highlighted an increase in Electric Vehicle (EV) and Plug-<br />

In Hybrid Vehicle (PHEV) sales of 72.7% in May <strong>2018</strong> alone. This contrasts<br />

sharply with the decrease in diesel vehicle sales, which fell by 23.6% in the<br />

same month. <strong>Marina</strong> services specialist Rolec Services, swift to recognise<br />

the importance of the EV market some eight years ago, offers equipment -<br />

and advice.<br />

Rolec’s sub-division, Rolec EV,<br />

claimed to be the UK’s largest<br />

manufacturer of EV charging<br />

equipment, offering Europe’s widest<br />

range of products, has sold over<br />

95,000 charging points to date. There<br />

is increasing demand in the marina<br />

sector.<br />

Holly Brown, Rolec operations<br />

director, explains: “The number of<br />

EVs/PHEVs populating the world’s<br />

roads continues to increase at a huge<br />

rate. The EV drivers visiting marinas<br />

generally park the vehicle in the marina<br />

car park, and as such will be looking<br />

to charge the vehicle while they are<br />

boating. Therefore, having EV charging<br />

points available at marinas seems the<br />

logical thing to do.”<br />

According to Brown, Rolec has<br />

developed a range of EV charging<br />

solutions to suit any marina or car<br />

park requirements, from simple freeto-charge<br />

pedestals through to more<br />

sophisticated charging points offering<br />

a pay by mobile phone experience.<br />

In addition to the more traditional AC<br />

fast charging units the company also<br />

offers a range of cutting edge DC<br />

rapid and ultrafast chargers that<br />

can charge a vehicle in 15 minutes<br />

at up to 150kW, enabling it to travel<br />

in some cases up to 300 miles<br />

(480km) until the next charge.<br />

“According to a recent report by<br />

the International Energy Agency,<br />

the number of EVs on the world’s<br />

roads is likely to more than triple to<br />

13 million in the next 18 months,”<br />

Brown reveals. “Sales are also<br />

expected to be set to soar 24% every<br />

year, on average, through to 2030.”<br />

“With environmental issues, including<br />

air quality, greenhouse gases, etc.<br />

being at the forefront of people’s minds,<br />

governments around the world are<br />

investing heavily – including providing<br />

subsidies to encourage the uptake of<br />

EVs/PHEVs. Further investment from<br />

governments includes financial support<br />

to develop national EV charging<br />

infrastructures in domestic, commercial<br />

and public locations,” she notes.<br />

“It is precisely because of all the<br />

positives EVs bring that pioneering<br />

marinas throughout the world are<br />

investing in EV charging points for their<br />

staff, visitors and customers.”<br />

According to Rolec, as well<br />

as providing a service to marina<br />

customers the deployment of EV<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 25

ENVIRONMENTAL MANAGEMENT<br />

charging points can also provide a new<br />

and additional revenue stream; with<br />

recent calculations suggesting that a<br />

charging point used once per day will<br />

repay its investment in less than 24<br />

months.<br />

Kate Broom, Rolec international<br />

marina sales manager, comments:<br />

“Whilst carrying out our standard<br />

marina services, designs and<br />

quotations I have noticed a significant<br />

increase in requests for EV charging<br />

points. It is clear from this rise in<br />

demand that many marina customers<br />

are now arriving in EVs and PHEVs,<br />

expecting to see charging points<br />

available at the marina.”<br />

Broom believes that this demand<br />

will continue to grow as vehicle<br />

manufacturers significantly increase<br />

their EV and PHEV portfolios over the<br />

next two to three years. And the good<br />

news is that it’s fairly straightforward for<br />

marina operators to meet their needs.<br />

“Installing an EV charging point is<br />

relatively easy and cost effective, and<br />

once installed is intuitive for the end<br />

user to operate,” Broom adds.<br />

Rolec confirms that its EV charging<br />

points are designed and manufactured<br />

to international EV charging standards<br />

and are compatible with all EVs and<br />

PHEVs currently on the market.<br />

The company also confirms that<br />

its charging points have been tested,<br />

approved and certificated by many<br />

of the world’s leading EV/PHEV<br />

manufacturers, including Nissan,<br />

Renault, Kia, Hyundai and Mitsubishi.<br />

E: rolec@rolecserv.co.uk<br />

Masterplanning<br />

Feasibility studies & market research<br />

Business planning<br />

<strong>Marina</strong> & <strong>Marina</strong> Club design<br />

Tender & project management<br />

Operational management<br />

Environmental & legislative advice<br />

Property consultancy services<br />

www.marinaprojects.com<br />

enquiries@marinaprojects.com<br />

+44 23 9252 6688<br />

+852 3796 3533<br />

132x182_<strong>Marina</strong> <strong>World</strong>_JAN18.indd 1 01/02/<strong>2018</strong> 13:15<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 27

Kropf Industrial also manufactures<br />

Conolift hydraulic boat trailers and<br />

mobile boat hoists with capacities<br />

from 3 – 100 tons.<br />

www.kropfindustrial.com info@kropfindustrial.com 888.480.3777<br />

Maricer (CPES Ltd)<br />

Vale Industrial Estate,<br />

Spilsby,<br />

Lincolnshire<br />

PE23 5HE<br />

UK<br />

If you change<br />

nothing<br />

Nothing will<br />

change<br />

Change to the<br />

world of<br />

www.maricer.com<br />

sales@maricer.com<br />

Call Now On +44 (0) 1790 753164

ENVIRONMENTAL MANAGEMENT<br />

Slipway mat with<br />

wash water collection<br />

French company CarenEcolo, the developer of a mobile system for collecting<br />

and filtering wash water contaminated by antifouling paint, has released a<br />

special hard rubber slipway mat.<br />

Influenced by the traditional way<br />

boats are hauled and cleaned in<br />

Brittany, the submersible mat can be<br />

Mussel power for<br />

cleaning water<br />

used on any hard surface whether flat<br />

or sloping.<br />

In Brittany the tide is used to bring<br />

Çeşme <strong>Marina</strong> in Turkey is working in cooperation with the Akua Group and<br />

Dokuz Eylül University to help clean seawater through the use of mussels.<br />

The marina is increasing the number of mussels living inside its waters as they<br />

are known to filter the water around them when searching for phytoplanktons to eat.<br />

Research shows that one mussel can filter 150 litres (33 gallons) of water per day<br />

depending on type and environmental conditions.<br />

During the first phase of the project,<br />

Çeşme <strong>Marina</strong> secured a total of 80 sacks<br />

of Mediterranean mussels in strategic<br />

locations around the marina. The ratio of<br />

heavy metals inside the mussels will be<br />

regularly checked and an academic report<br />

will be published after one year.<br />

Can Akaltan CMM, general manager of<br />

Çeşme <strong>Marina</strong>, says: “We are excited to<br />

conduct this project and aim to become a<br />

model for Turkish and European marina<br />

companies. If we can succeed we will<br />

recommend this to all marinas.”<br />

Çeşme <strong>Marina</strong>, a joint investment of<br />

Camper & Nicholsons <strong>Marina</strong>s and IC<br />

Holding, is located in the Çeşme region of<br />

Izmir and has 400 wet berths and capacity<br />

for 100 vessels ashore.<br />

a boat to the slipway and the time<br />

between high and low tide used to<br />

clean the hull and apply antifouling<br />

paint. This system has been in use for<br />

as long as slipways have existed as it<br />

costs nothing and there is no need for<br />

trailers or cranes.<br />

With the CarenEcolo product, the<br />

boat settles on the hard rubber mat<br />

and is high pressure washed. The wash<br />

water is collected and pumped into a<br />

tank or a mobile filtration unit. Paint is<br />

applied before the tide comes in to take<br />

the boat off the slipway.<br />

The mat is manufactured from threeply<br />

rubber to protect the boat hull and<br />

can be set up in marinas easily and<br />

inexpensively. The system can also be<br />

moved when and where needed.<br />

E: contact@carenecolo.fr<br />

ICMS to<br />

distribute<br />

Seabin<br />

Inland and Coastal <strong>Marina</strong><br />

Systems (ICMS) has been<br />

appointed exclusive distributor for<br />

Seabin in the UK and Ireland.<br />

The product (reviewed in <strong>Marina</strong><br />

<strong>World</strong> January/February <strong>2018</strong>) has<br />

been put to test around the world to<br />

collect plastic waste in harbours and<br />

marinas.<br />

Developed by two Australian<br />

surfers Pete Ceglinski and Andrew<br />

Turton, Seabin is manufactured by<br />

Poralu, which oversees sales and<br />

distribution.<br />

E: sales@inlandandcoastal.com<br />

www.marinaworld.com - <strong>July</strong>/<strong>August</strong> <strong>2018</strong> 29

SPONSORED FEATURE<br />

SPONSORED FEATURE: Poralu Marine<br />

Putting the planet first<br />

Vision, innovation, and environmental awareness and accountability, are<br />

ingrained in the Poralu Marine philosophy. Now well into its third decade of<br />

delivering turnkey marinas, the company continues to focus on developing<br />

unique and stylish solutions that protect and preserve ecosystems while<br />

offering yacht harbours long-lasting, good-looking products.<br />

Building a brand<br />

Say Poralu, think aluminium. The use of<br />

metal has been at the core of the Poralu<br />

Group since it was established back<br />

in 1968, and when Poralu Marine was<br />

set up 16 years later it launched into<br />

Region: Americas<br />

Project: Puerto Escondido, Mexico<br />

production of a ground breaking marina<br />

industry first; an aluminium pontoon<br />

system that has become a world leader.<br />

The company has built over 50,000<br />

berths around the world and now<br />

completes an average of 250 marina<br />

Designed and built in complete harmony with its spectacular natural<br />

surroundings, Puerto Escondido in the Gulf of California is a high-end<br />

facility that integrates private pontoons and a marina to provide over 100<br />

berths for boats up to 60m (197ft) in length. All design and manufacture<br />

was undertaken in Poralu’s production site in Quebec, and the project was<br />

conducted in partnership with Inland and Coastal <strong>Marina</strong> Systems (ICMS) as<br />

the first joint venture for the two companies in the Americas.<br />

In an impressive recycling move,<br />

Poralu was able to re-use pontoons<br />

it had installed on the site for the<br />

Mexican government agency<br />

FONATUR 15 years ago.<br />

They had fully resisted<br />

wear, tear and hurricanes<br />

and the modular sections<br />

fitted into the new units like<br />

a set of building blocks.<br />

The original anchor piles<br />

were replaced with an<br />

environmentally friendly<br />

Seaflex anchoring system.<br />

The marina owners<br />

also selected premium<br />

pontoons with Ecoteck<br />

wood composite decking<br />

for residential pontoons,<br />

and Nautic pontoons with Ecostyle<br />

polypropylene decking where<br />

additional pontoons were needed in<br />

the marina.<br />

Port Camargue, a 5,000+ berth<br />

facility in France, has been a<br />

Poralu customer for 20 years.<br />

projects per year, manufacturing around<br />

40,000m (131,234ft) of pontoons.<br />

Based in Port, eastern France, where<br />

it has its European production facilities,<br />

Poralu Marine was swift to gain market<br />

share on home ground and then to<br />

look for export opportunities. In 2000<br />

it set up Poralu Marine Australia and<br />

in 2002 Poralu Marine Canada. It now<br />

has a well established production unit<br />

in Quebec that serves the American<br />

region. The company further supports<br />

offices in Germany, the UK, China<br />

(Hong Kong), the UAE, Spain and Italy,<br />

has a network of agents in all main<br />

markets, and is currently building a third<br />

manufacturing facility in Iran with a view<br />

to better serving the Middle East region.<br />

Over the years, Poralu has completed<br />

over 8,000 marina projects. Highlights<br />

include Port Camargue, France, an<br />

expansive 5,000+ berth facility that has<br />

worked with Poralu for 20 years; Royal<br />

Perth Yacht Club, Australia; Haleh, Iran;<br />

Montreal <strong>Marina</strong>, Canada; Brooklyn<br />