CONSTRUCTION CHEMICALS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Megaİzo CT2/CT3 - CT3 Plus<br />

Fiberglass Reinforced, APP (Atactic Polypropylene) Modified<br />

Waterproofing Membrane With Plastometric Bitumen<br />

NEW<br />

PRODUCT DESCRIPTION<br />

Waterproofing membrane with plastomeric bitumen, have physical resistance with fiberglass,<br />

and both sides of which are coated with polyethylene film.<br />

AREAS OF USE<br />

Suitable for use in balconies, terraces, flat and inclined roofs, window boxes, water canals,<br />

artificial ponds and swimming pools.<br />

PRODUCT ADVANTAGES<br />

• Crease during the application, and pose a smooth appearance.<br />

• Megaİzo CT2 / CT3 is ideal for use in hot, temperate and moderate climate zones;<br />

Megaİzo CT3 Plus is ideal for use in hot and cold (continental) climate zones.<br />

• Megaİzo CT2 / CT3 easily applicable under high temperature conditions.<br />

• Fit for application to any surface.<br />

• Easily applied to such surfaces as chimney flashings and parapets.<br />

• Ensure waterproofing throughout the life cycle of the building.<br />

• Prior to the application, the consumption amount can be clearly and precisely determined.<br />

• Pose high level of resistance to ground waters, which contain hazardous chemicals such as<br />

sulfate.<br />

• Free from any hazardous materials. The products do not pose any threats to human health<br />

and the environment.<br />

• Elastic.<br />

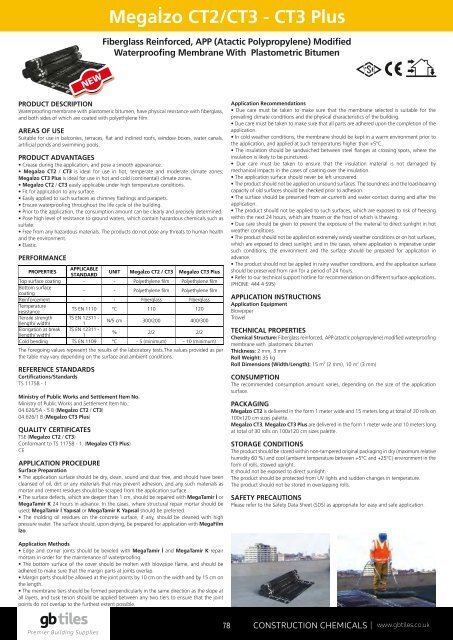

PERFORMANCE<br />

PROPERTIES<br />

APPLICABLE<br />

STANDARD<br />

UNIT Megaİzo CT2 / CT3 Megaİzo CT3 Plus<br />

Top surface coating - - Polyethylene film Polyethylene film<br />

Bottom surface<br />

coating<br />

- - Polyethylene film Polyethylene film<br />

Reinforcement - - Fiberglass Fiberglass<br />

Temperature<br />

resistance<br />

TS EN 1110 °C 110 120<br />

Tensile strength TS EN 12311 -<br />

(length/ width)<br />

1<br />

N/5 cm 300/200 400/300<br />

Elongation at break TS EN 12311 -<br />

(length/ width)<br />

1<br />

% 2/2 2/2<br />

Cold bending TS EN 1109 °C - 5 (minimum) - 10 (minimum)<br />

The foregoing values represent the results of the laboratory tests.The values provided as per<br />

the table may vary depending on the surface and ambient conditions.<br />

REFERENCE STANDARDS<br />

Certifications/Standards<br />

TS 11758 - 1<br />

Ministry of Public Works and Settlement Item No.<br />

Ministry of Public Works and Settlement Item No.:<br />

04.626/5A - 5 B (Megaİzo CT2 / CT3)<br />

04.626/1 B (Megaİzo CT3 Plus)<br />

QUALITY CERTIFICATES<br />

TSE (Megaİzo CT2 / CT3)<br />

Conformant to TS 11758 - 1. (Megaİzo CT3 Plus)<br />

CE<br />

APPLICATION PROCEDURE<br />

Surface Preparation<br />

• The application surface should be dry, clean, sound and dust free, and should have been<br />

cleansed of oil, dirt or any materials that may prevent adhesion, and any such materials as<br />

mortar and cement residues should be scraped from the application surface.<br />

• The surface defects, which are deeper than 1 cm, should be repaired with MegaTamir İ or<br />

MegaTamir K 24 hours in advance. In the cases, where structural repair mortar should be<br />

used; MegaTamir İ Yapısal or MegaTamir K Yapısal should be preferred.<br />

• The molding oil residues on the concrete surface, if any, should be cleaned with high<br />

pressure water. The surface should, upon drying, be prepared for application with MegaFilm<br />

İzo.<br />

Application Recommendations<br />

• Due care must be taken to make sure that the membrane selected is suitable for the<br />

prevailing climate conditions and the physical characteristics of the building.<br />

• Due care must be taken to make sure that all parts are adhered upon the completion of the<br />

application.<br />

• In cold weather conditions, the membrane should be kept in a warm environment prior to<br />

the application, and applied at such temperatures higher than +5°C.<br />

• The insulation should be sandwiched between steel flanges at crossing spots, where the<br />

insulation is likely to be punctured.<br />

• Due care must be taken to ensure that the insulation material is not damaged by<br />

mechanical impacts in the cases of coating over the insulation.<br />

• The application surface should never be left uncovered.<br />

• The product should not be applied on unsound surfaces. The soundness and the load-bearing<br />

capacity of old surfaces should be checked prior to adhesion.<br />

• The surface should be preserved from air currents and water contact during and after the<br />

application.<br />

• The product should not be applied to such surfaces, which are exposed to risk of freezing<br />

within the next 24 hours, which are frozen or the frost of which is thawing.<br />

• Due care should be given to prevent the exposure of the material to direct sunlight in hot<br />

weather conditions.<br />

• The product should not be applied on extremely windy weather conditions or on hot surfaces,<br />

which are exposed to direct sunlight; and in the cases, where application is imperative under<br />

such conditions, the environment and the surface should be prepared for application in<br />

advance.<br />

• The product should not be applied in rainy weather conditions, and the application surface<br />

should be preserved from rain for a period of 24 hours.<br />

• Refer to our technical support hotline for recommendation on different surface applications.<br />

(PHONE: 444 4 595)<br />

APPLICATION INSTRUCTIONS<br />

Application Equipment<br />

Blowpiper<br />

Trowel<br />

TECHNICAL PROPERTIES<br />

Chemical Structure: Fiberglass reinforced, APP (atactic polypropylene) modified waterproofing<br />

membrane with plastomeric bitumen<br />

Thickness: 2 mm, 3 mm<br />

Roll Weight: 35 kg<br />

Roll Dimensions (Width/Length): 15 m 2 (2 mm), 10 m 2 (3 mm)<br />

CONSUMPTION<br />

The recommended consumption amount varies, depending on the size of the application<br />

surface.<br />

PACKAGING<br />

Megaİzo CT2 is delivered in the form 1 meter wide and 15 meters long at total of 30 rolls on<br />

100x120 cm sizes palette.<br />

Megaİzo CT3, Megaİzo CT3 Plus are delivered in the form 1 meter wide and 10 meters long<br />

at total of 30 rolls on 100x120 cm sizes palette.<br />

STORAGE CONDITIONS<br />

The product should be stored within non-tampered original packaging in dry (maximum relative<br />

humidity 60 %) and cool (ambient temperature between +5°C and +25°C) environment in the<br />

form of rolls, stowed upright.<br />

It should not be exposed to direct sunlight.<br />

The product should be protected from UV lights and sudden changes in temperature.<br />

The product should not be stored in overlapping rolls.<br />

SAFETY PRECAUTIONS<br />

Please refer to the Safety Data Sheet (SDS) as appropriate for easy and safe application.<br />

Application Methods<br />

• Edge and corner joints should be beveled with MegaTamir İ and MegaTamir K repair<br />

mortars in order for the maintenance of waterproofing.<br />

• The bottom surface of the cover should be molten with blowpipe flame, and should be<br />

adhered to make sure that the margin parts at joints overlap.<br />

• Margin parts should be allowed at the joint points by 10 cm on the width and by 15 cm on<br />

the length.<br />

• The membrane tiers should be formed perpendicularly in the same direction as the slope at<br />

all layers, and tusk tenon should be applied between any two tiers to ensure that the joint<br />

points do not overlap to the furthest extent possible.<br />

78