Sept Oct Hi Res with ads

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

16 MACHINERY UPDATE SEPTEMBER/OCTOBER 2018 www.machineryupdate.co.uk<br />

New Machinery<br />

Mark & Read<br />

technology<br />

is evolving<br />

A joint engineering and<br />

commercial initiative from<br />

Markem-Imaje and Cognex is<br />

designed to develop an even more<br />

advanced and integrated solution<br />

for manufacturers to ensure the<br />

accuracy of coding on their packs.<br />

Since 2015, Mark & Read,<br />

an automated Cognex camera<br />

and Markem-Imaje printer<br />

verification solution, has helped<br />

companies confirm the right code<br />

is correctly printed every time,<br />

reducing unnecessary waste<br />

and helping ensure non-coding<br />

related recalls run more smoothly.<br />

Today, the two companies<br />

are deepening their existing<br />

partnership to develop the next<br />

generation of Mark & Read<br />

applications for global fmcg<br />

companies. Both companies’<br />

research and development and<br />

commercial teams will be working<br />

more closely together to integrate<br />

their printing and reading solutions,<br />

collaborating at regional and<br />

global levels on opportunities and<br />

projects in the packaging market.<br />

FASTER VERIFICATION<br />

It is thought that by working<br />

together earlier in the<br />

engineering design process, they<br />

will ensure their products work<br />

seamlessly together to provide<br />

even quicker and more accurate<br />

code verification. Manufacturers<br />

will also benefit from a more<br />

intuitive user experience – from<br />

setup through to full-production.<br />

Manufacturers can expect to<br />

see the first of a new generation<br />

of Mark & Read solutions by<br />

the end of this year, <strong>with</strong> a range<br />

of additional improvements<br />

available in 2019.<br />

“Together <strong>with</strong> Markem-Imaje,<br />

we are building new capabilities<br />

for printing product quality and<br />

eliminating production errors,”<br />

says Robert Willett, ceo of the<br />

Cognex Corporation.<br />

T 01327 856040<br />

W www.cognex.com<br />

T 0161 864 8111<br />

W www.markem-imaje.co.uk<br />

Agile and compact co-bot<br />

integrates easily into lines<br />

ABB says its new singlearm<br />

YuMi is its most<br />

agile and compact<br />

collaborative robot (co-bot) yet<br />

and can easily integrate into<br />

existing production lines.<br />

The company expanded<br />

its collaborative automation<br />

offering <strong>with</strong> the launch of<br />

a new single-arm YuMi robot<br />

earlier this year at Automatica<br />

2018 in Munich. The IRB 14050<br />

single-arm YuMi is designed<br />

to easily fit into existing<br />

production lines to increase<br />

flexibility while working safely<br />

alongside people.<br />

This new co-bot is one of<br />

the first of a new generation<br />

of robots from ABB to be built<br />

on a flexible new modular<br />

design platform that will allow<br />

a greater variety of robots and<br />

sizes, and also more<br />

tailored solutions.<br />

Weighing less than 10 kg,<br />

and capable of being mounted<br />

from a ceiling, table and<br />

wall, this new addition to the<br />

YuMi family offers increased<br />

flexibility to help meet highmix,<br />

low volume production<br />

in short cycles. Easy to install,<br />

Starchless depositing covers the complete<br />

range of jellies and also gummies sweets<br />

Jellies and gummies of any<br />

texture, from soft pectin jellies<br />

to chewy gelatin gummies, can<br />

now be made economically by<br />

the Baker Perkins starchless<br />

depositing process.<br />

Gelatin gummies can<br />

now be removed from the<br />

moulds in a few minutes,<br />

rather than 24 hours, through<br />

a combination of gelatin<br />

producer Rousselot’s new<br />

SiMoGel solution, and Baker<br />

Perkins ServoForm depositors<br />

and cooking systems.<br />

The second innovation,<br />

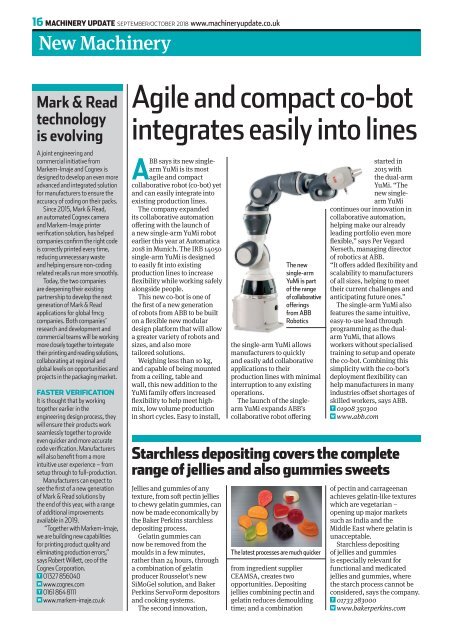

The new<br />

single-arm<br />

YuMi is part<br />

of the range<br />

of collaborative<br />

offerings<br />

from ABB<br />

Robotics<br />

the single-arm YuMi allows<br />

manufacturers to quickly<br />

and easily add collaborative<br />

applications to their<br />

production lines <strong>with</strong> minimal<br />

interruption to any existing<br />

operations.<br />

The launch of the singlearm<br />

YuMi expands ABB’s<br />

collaborative robot offering<br />

The latest processes are much quicker<br />

from ingredient supplier<br />

CEAMSA, creates two<br />

opportunities. Depositing<br />

jellies combining pectin and<br />

gelatin reduces demoulding<br />

time; and a combination<br />

started in<br />

2015 <strong>with</strong><br />

the dual-arm<br />

YuMi. “The<br />

new singlearm<br />

YuMi<br />

continues our innovation in<br />

collaborative automation,<br />

helping make our already<br />

leading portfolio even more<br />

flexible,” says Per Vegard<br />

Nerseth, managing director<br />

of robotics at ABB.<br />

“It offers added flexibility and<br />

scalability to manufacturers<br />

of all sizes, helping to meet<br />

their current challenges and<br />

anticipating future ones.”<br />

The single-arm YuMi also<br />

features the same intuitive,<br />

easy-to-use lead through<br />

programming as the dualarm<br />

YuMi, that allows<br />

workers <strong>with</strong>out specialised<br />

training to setup and operate<br />

the co-bot. Combining this<br />

simplicity <strong>with</strong> the co-bot’s<br />

deployment flexibility can<br />

help manufacturers in many<br />

industries offset shortages of<br />

skilled workers, says ABB.<br />

T 01908 350300<br />

W www.abb.com<br />

of pectin and carrageenan<br />

achieves gelatin-like textures<br />

which are vegetarian –<br />

opening up major markets<br />

such as India and the<br />

Middle East where gelatin is<br />

unacceptable.<br />

Starchless depositing<br />

of jellies and gummies<br />

is especially relevant for<br />

functional and medicated<br />

jellies and gummies, where<br />

the starch process cannot be<br />

considered, says the company.<br />

T 01733 283000<br />

W www.bakerperkins.com