Sept Oct Hi Res with ads

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

24 MACHINERY UPDATE SEPTEMBER/OCTOBER 2018 www.machineryupdate.co.uk<br />

New Machinery<br />

Screw conveyor is good<br />

for low-headroom areas<br />

The automated palletiser is safer<br />

Robotic<br />

palletiser is<br />

flexible<br />

Active8 Robots is offering the<br />

Attollo series palletiser, designed<br />

as a compact and also mobile<br />

machine that reduces labour<br />

costs while lowering health and<br />

safety risks associated <strong>with</strong><br />

manual handling.<br />

With a footprint of just 2 x 2.2<br />

metres, the Attollo takes up very<br />

little space on the factory floor.<br />

The ease of relocation means it<br />

offers speed and flexibility when<br />

setting up a production line which,<br />

says the company, makes it ideal<br />

for long or short production runs.<br />

The Attollo is safe to use as it<br />

is fully guarded, <strong>with</strong> pallet entry<br />

and box infeed light guarded for<br />

ease of access.<br />

In operation, complex pallet<br />

layers can be easily configured<br />

<strong>with</strong>out any specialist<br />

programming knowledge. Just<br />

rotate and nudge individual boxes<br />

to create complex layer patterns.<br />

In terms of tooling, the<br />

standard head can handle<br />

multiple case types and sizes,<br />

including shrink wrapped and riptop<br />

packaging. Custom tooling is<br />

also available for any nonstandard<br />

packaging applications.<br />

As for the infeed, the 1.5 metre<br />

buffer conveyor has adjustable<br />

infeed height to make it easy to<br />

interface <strong>with</strong> existing equipment<br />

and therefore minimising any<br />

setup time.<br />

The company works in many<br />

industry sectors including food<br />

and beverage, pharmaceuticals,<br />

plastics, automotive,<br />

manufacturing and co-packing.<br />

T 01761 234376<br />

W www.active8robots.com<br />

Anew low profile flexible<br />

screw conveyor <strong>with</strong><br />

integral bin and castormounted<br />

frame is now<br />

available from Flexicon.<br />

It can roll below mezzanines<br />

and other low-headroom<br />

areas, receive material from<br />

overhead equipment, and<br />

discharge the material into<br />

process equipment and<br />

vessels throughout the plant.<br />

Ready to plug-in and<br />

run, the self-contained unit<br />

features a ‘push type’ drive<br />

system positioned at the<br />

lower intake end of the<br />

conveyor, versus a standard<br />

‘pull-type’ drive positioned<br />

at the upper discharge end<br />

of the conveyor, reducing<br />

overall height by<br />

approximately 610 mm.<br />

INTEGRAL BIN IS LARGE<br />

At 250 litres, the integral bin<br />

accommodates the contents of<br />

approximately one-third<br />

of a bulk bag measuring<br />

1 x 1 x 1 metres, or several<br />

typical 25 kg bags, depending<br />

on bulk density.<br />

A specialised Bev-Con screw<br />

tna has introduced the tna<br />

intelli-sys iPS 3, a fully<br />

integrated data collection<br />

and reporting tool to<br />

provide manufacturers <strong>with</strong><br />

unprecedented insights into all<br />

of their production processes.<br />

With the new tna intellisys<br />

iPS 3 software, food<br />

manufacturers will be able<br />

to use a single standardised<br />

platform to collate, visualise<br />

and evaluate live and historical<br />

information from every part<br />

of the production chain and<br />

across multiple locations.<br />

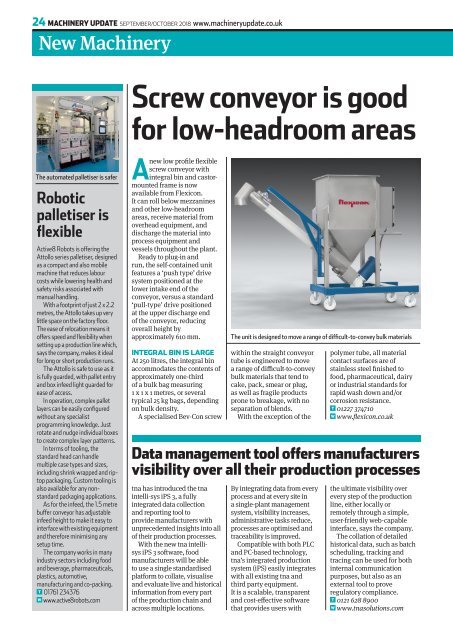

The unit is designed to move a range of difficult-to-convey bulk materials<br />

<strong>with</strong>in the straight conveyor<br />

tube is engineered to move<br />

a range of difficult-to-convey<br />

bulk materials that tend to<br />

cake, pack, smear or plug,<br />

as well as fragile products<br />

prone to breakage, <strong>with</strong> no<br />

separation of blends.<br />

With the exception of the<br />

Data management tool offers manufacturers<br />

visibility over all their production processes<br />

By integrating data from every<br />

process and at every site in<br />

a single-plant management<br />

system, visibility increases,<br />

administrative tasks reduce,<br />

processes are optimised and<br />

traceability is improved.<br />

Compatible <strong>with</strong> both PLC<br />

and PC-based technology,<br />

tna’s integrated production<br />

system (iPS) easily integrates<br />

<strong>with</strong> all existing tna and<br />

third party equipment.<br />

It is a scalable, transparent<br />

and cost-effective software<br />

that provides users <strong>with</strong><br />

polymer tube, all material<br />

contact surfaces are of<br />

stainless steel finished to<br />

food, pharmaceutical, dairy<br />

or industrial standards for<br />

rapid wash down and/or<br />

corrosion resistance.<br />

T 01227 374710<br />

W www.flexicon.co.uk<br />

the ultimate visibility over<br />

every step of the production<br />

line, either locally or<br />

remotely through a simple,<br />

user-friendly web-capable<br />

interface, says the company.<br />

The collation of detailed<br />

historical data, such as batch<br />

scheduling, tracking and<br />

tracing can be used for both<br />

internal communication<br />

purposes, but also as an<br />

external tool to prove<br />

regulatory compliance.<br />

T 0121 628 8900<br />

W www.tnasolutions.com