Maintworld 3/2018

Are You Overlooking a Significant Source of Savings? // Advantages of broadband ultrasonic analysis // Are you in the “circle of despair”? // Future of work

Are You Overlooking a Significant Source

of Savings? // Advantages of broadband ultrasonic analysis // Are you in the “circle of despair”? // Future of work

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

standardisation<br />

Standards Increase<br />

Economic Growth and<br />

Help Companies Access<br />

Foreign Markets<br />

Nina Garlo-Melkas<br />

Standardisation is a key to a well-functioning,<br />

economically prospering and<br />

sustainable society. It is also a way to<br />

increase economic growth. These conclusions<br />

can be made from the results of<br />

the new study “The Influence of Standards<br />

on the Nordic Economies”.<br />

A study on the impact of standardisation was conducted in<br />

the five Nordic countries, Sweden, Finland, Norway, Denmark<br />

and Iceland. In total 1,179 Nordic companies in different<br />

industries with prior experience from the use of standards<br />

took part in the study.<br />

One of the most important findings of it is that standardisation<br />

was associated with 28 percent of GDP growth in the<br />

Nordic countries between 1976 and 2014. The value of standards<br />

derives mainly from increased productivity and efficiency.<br />

The study shows, for example, that doubling the stock of<br />

standards in an economy is associated with an increase of 10.5<br />

percent in labour productivity. On average, standardisation is<br />

associated with an annual increase in labour productivity of<br />

0.7 percent per year.<br />

- The efficiency and economic gains that companies get<br />

from standardisation reflect highly to the welfare of each<br />

country. When companies are prospering and effective the<br />

customers – the citizens – get the best quality in products and<br />

a well-functioning society. Standards can also guide companies<br />

to operate more ecologically and with solid processes, says<br />

Thomas Idermark, CEO at SIS, Swedish Standards Institute.<br />

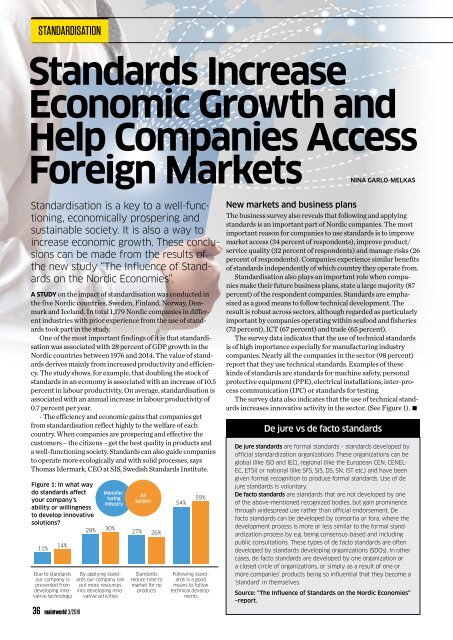

Figure 1: In what way<br />

do standards affect<br />

your company's<br />

ability or willingness<br />

to develop innovative<br />

solutions?<br />

11%<br />

14%<br />

Due to standards<br />

our company is<br />

prevented from<br />

developing innovative<br />

technology<br />

36 maintworld 3/<strong>2018</strong><br />

Manufacturing<br />

industry<br />

28% 30%<br />

By applying standards<br />

our company can<br />

put more resources<br />

into developing innovative<br />

activities<br />

All<br />

Sectors<br />

27% 26%<br />

Standards<br />

reduce time to<br />

market for ne<br />

products<br />

54%<br />

59%<br />

Following standards<br />

is a good<br />

means to follow<br />

technical developments<br />

New markets and business plans<br />

The business survey also reveals that following and applying<br />

standards is an important part of Nordic companies. The most<br />

important reason for companies to use standards is to improve<br />

market access (34 percent of respondents), improve product/<br />

service quality (32 percent of respondents) and manage risks (26<br />

percent of respondents). Companies experience similar benefits<br />

of standards independently of which country they operate from.<br />

Standardisation also plays an important role when companies<br />

make their future business plans, state a large majority (87<br />

percent) of the respondent companies. Standards are emphasized<br />

as a good means to follow technical development. The<br />

result is robust across sectors, although regarded as particularly<br />

important by companies operating within seafood and fisheries<br />

(73 percent), ICT (67 percent) and trade (65 percent).<br />

The survey data indicates that the use of technical standards<br />

is of high importance especially for manufacturing industry<br />

companies. Nearly all the companies in the sector (98 percent)<br />

report that they use technical standards. Examples of these<br />

kinds of standards are standards for machine safety, personal<br />

protective equipment (PPE), electrical installations, inter-process<br />

communication (IPC) or standards for testing.<br />

The survey data also indicates that the use of technical standards<br />

increases innovative activity in the sector. (See Figure 1).<br />

De jure vs de facto standards<br />

De jure standards are formal standards – standards developed by<br />

official standardization organizations .These organizations can be<br />

global (like ISO and IEC), regional (like the European CEN, CENEL-<br />

EC, ETSI) or national (like SFS, SIS, DS, SN, IST etc.) and have been<br />

given formal recognition to produce formal standards. Use of de<br />

jure standards is voluntary.<br />

De facto standards are standards that are not developed by one<br />

of the above-mentioned recognized bodies, but gain prominence<br />

through widespread use rather than official endorsement. De<br />

facto standards can be developed by consortia or fora, where the<br />

development process is more or less similar to the formal standardization<br />

process by e.g. being consensus-based and including<br />

public consultations. These types of de facto standards are often<br />

developed by standards developing organizations (SDOs). In other<br />

cases, de facto standards are developed by one organization or<br />

a closed circle of organizations, or simply as a result of one or<br />

more companies’ products being so influential that they become a<br />

‘standard’ in themselves.<br />

Source: “The Influence of Standards on the Nordic Economies”<br />

–report.