Maintworld 3/2018

Are You Overlooking a Significant Source of Savings? // Advantages of broadband ultrasonic analysis // Are you in the “circle of despair”? // Future of work

Are You Overlooking a Significant Source

of Savings? // Advantages of broadband ultrasonic analysis // Are you in the “circle of despair”? // Future of work

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Market review<br />

An Overview of the Current<br />

Status of the Japanese<br />

Maintenance Market<br />

The Japanese plant maintenance<br />

industry supports the domestic<br />

manufacturing industry, which has<br />

over 500 billion euro of GDP. The<br />

plant maintenance industry has been<br />

growing steadily for years, as has the<br />

domestic manufacturing industries as<br />

result of the economic growth in China<br />

and South East Asia.<br />

IIoT for Asset-Maintenance and Predictive<br />

Analysis<br />

Recent developments in smart sensors and the processing of big<br />

data have increased the need for integration of new technology<br />

and existing operational and maintenance tasks. This area supported<br />

by advanced computer science is actively ongoing and<br />

rapidly developing in the Plant Maintenance sector in Japan.<br />

For example, in the last Plant Maintenance Show in Tokyo held<br />

in July <strong>2018</strong>, it could be seen that major vendors are concentrating<br />

on IIoT for predictive-maintenance. It is obvious that more<br />

attention has recently been paid to IIoT technology from their<br />

customers, particularly in the management level of the plant<br />

operation as shown in a survey summarized in Figure 2.<br />

Akio Yamamoto,<br />

D.Sc. (Tech.), LignoGate<br />

Author of this article: Akio Yamamoto,<br />

D.Sc. (Tech.), Specialist in Forest products<br />

technology at LignoGate<br />

Dr. Yamamoto has more than 10 years’ experience in Chemical<br />

engineering and Forest products technology. His career started<br />

in pulp and paper R&D as a Chemical research engineer, where<br />

he was involved in the development of an on-line chemical<br />

analyzer for pulp and paper plants. His expertise includes Pulp<br />

and Paper technology, Process technologies, equipment and<br />

systems and IPRs in these fields. Recently he has primarily<br />

supported SMEs and large enterprises on market analysis for<br />

the Japanese market and consulting on finding their potential<br />

business partners in Japan.<br />

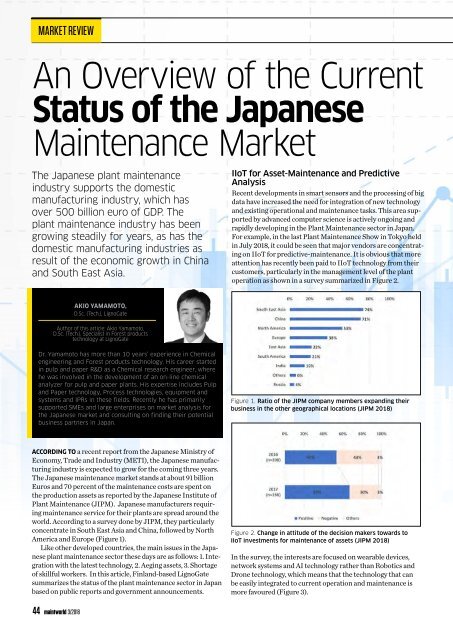

Figure 1. Ratio of the JIPM company members expanding their<br />

business in the other geographical locations (JIPM <strong>2018</strong>)<br />

According to a recent report from the Japanese Ministry of<br />

Economy, Trade and Industry (METI), the Japanese manufacturing<br />

industry is expected to grow for the coming three years.<br />

The Japanese maintenance market stands at about 91 billion<br />

Euros and 70 percent of the maintenance costs are spent on<br />

the production assets as reported by the Japanese Institute of<br />

Plant Maintenance (JIPM). Japanese manufacturers requiring<br />

maintenance service for their plants are spread around the<br />

world. According to a survey done by JIPM, they particularly<br />

concentrate in South East Asia and China, followed by North<br />

America and Europe (Figure 1).<br />

Like other developed countries, the main issues in the Japanese<br />

plant maintenance sector these days are as follows: 1. Integration<br />

with the latest technology, 2. Aeging assets, 3. Shortage<br />

of skillful workers. In this article, Finland-based LignoGate<br />

summarizes the status of the plant maintenance sector in Japan<br />

based on public reports and government announcements.<br />

Figure 2. Change in attitude of the decision makers towards to<br />

IIoT investments for maintenance of assets (JIPM <strong>2018</strong>)<br />

In the survey, the interests are focused on wearable devices,<br />

network systems and AI technology rather than Robotics and<br />

Drone technology, which means that the technology that can<br />

be easily integrated to current operation and maintenance is<br />

more favoured (Figure 3).<br />

44 maintworld 3/<strong>2018</strong>