CRAFT DOC_compressed

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5.5 Diya/lamp making<br />

The iron sheet used to make diyas/lamps<br />

is of 18-16 gauge thickness (same as that<br />

of panels). First, a half-circle is cut out<br />

of the sheet, roughly, using a chisel and<br />

hammer, and then another adjoining<br />

half-circle is cut, with a rectangular<br />

extension from the circular shape, for<br />

riveting. The cut-out measures about 6<br />

cm in diameter and 8 cm in length. It is<br />

beaten on its edges to blunt them.<br />

To give it a concave shape, it is placed<br />

on a large bearing (their local dapping<br />

tool which they procure from waste),<br />

and beaten over from the narrower end<br />

of the hammer, skilfully. More depth can<br />

be achieved by heating the diya/lamp in<br />

the furnace 2-3 times alternating with<br />

hammering. It is then kept at the edge of<br />

the pattri/rail and hammered with the<br />

broader end of the hammer to create a<br />

Fig. 5.88<br />

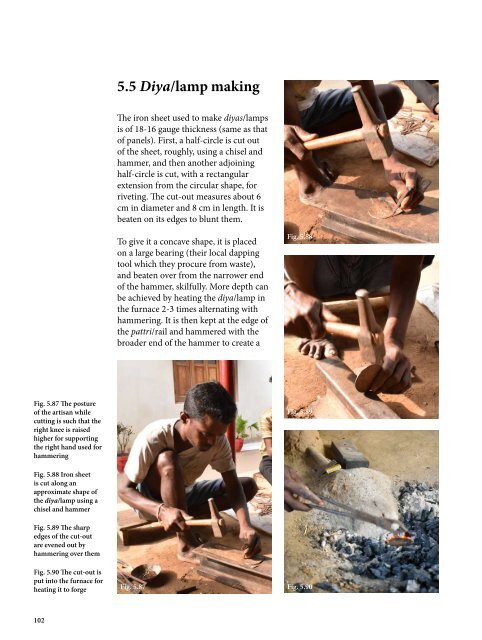

Fig. 5.87 The posture<br />

of the artisan while<br />

cutting is such that the<br />

right knee is raised<br />

higher for supporting<br />

the right hand used for<br />

hammering<br />

Fig. 5.89<br />

Fig. 5.88 Iron sheet<br />

is cut along an<br />

approximate shape of<br />

the diya/lamp using a<br />

chisel and hammer<br />

Fig. 5.89 The sharp<br />

edges of the cut-out<br />

are evened out by<br />

hammering over them<br />

Fig. 5.90 The cut-out is<br />

put into the furnace for<br />

heating it to forge Fig. 5.87<br />

Fig. 5.90<br />

102