CRAFT DOC_compressed

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

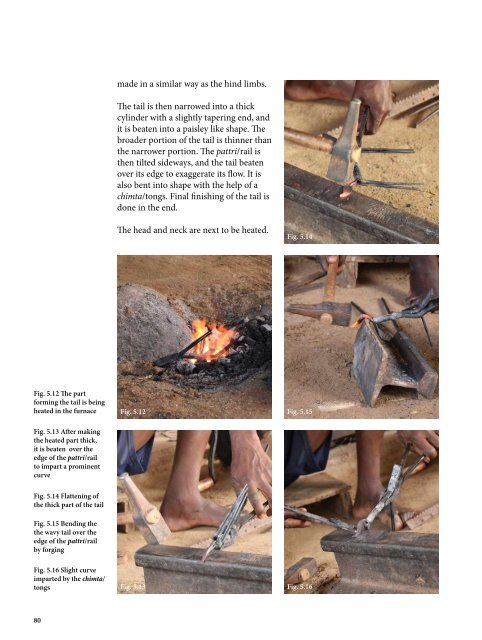

made in a similar way as the hind limbs.<br />

The tail is then narrowed into a thick<br />

cylinder with a slightly tapering end, and<br />

it is beaten into a paisley like shape. The<br />

broader portion of the tail is thinner than<br />

the narrower portion. The pattri/rail is<br />

then tilted sideways, and the tail beaten<br />

over its edge to exaggerate its flow. It is<br />

also bent into shape with the help of a<br />

chimta/tongs. Final finishing of the tail is<br />

done in the end.<br />

The head and neck are next to be heated.<br />

Fig. 5.14<br />

Fig. 5.12 The part<br />

forming the tail is being<br />

heated in the furnace<br />

Fig. 5.12<br />

Fig. 5.15<br />

Fig. 5.13 After making<br />

the heated part thick,<br />

it is beaten over the<br />

edge of the pattri/rail<br />

to impart a prominent<br />

curve<br />

Fig. 5.14 Flattening of<br />

the thick part of the tail<br />

Fig. 5.15 Bending the<br />

the wavy tail over the<br />

edge of the pattri/rail<br />

by forging<br />

Fig. 5.16 Slight curve<br />

imparted by the chimta/<br />

tongs<br />

Fig. 5.13<br />

Fig. 5.16<br />

80