CRAFT DOC_compressed

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The part is elongated and hammered<br />

into a thinner cylinder, yet not as narrow<br />

as the limbs. The neck is slightly bent<br />

and flattened to provide surface area for<br />

fixing the head later on.<br />

The head, ears and antlers are made<br />

separately by taking another 3mm thick<br />

metal strip of approximate dimensions<br />

15cm x 2cm. Slits are made according<br />

to the placement of the antlers and<br />

ears. Each part of the antler is shaped<br />

separately.<br />

The center portion of the antlers, where<br />

the ears and mouth are positioned, was<br />

broadened by hammering to give the<br />

desired shape.<br />

With the help of two chimtas, the antlers<br />

are then folded from the center and<br />

hammered to make a narrow V. This will<br />

form the head which is then temporarily<br />

attached to the body of the deer sculpture<br />

by hammering.<br />

The joinery is made permanent by<br />

applying wet mud over the head and<br />

keeping it next to the furnace to impart<br />

heat for drying. Then, the head is put<br />

into the furnace to make it red hot and<br />

Fig. 5.18<br />

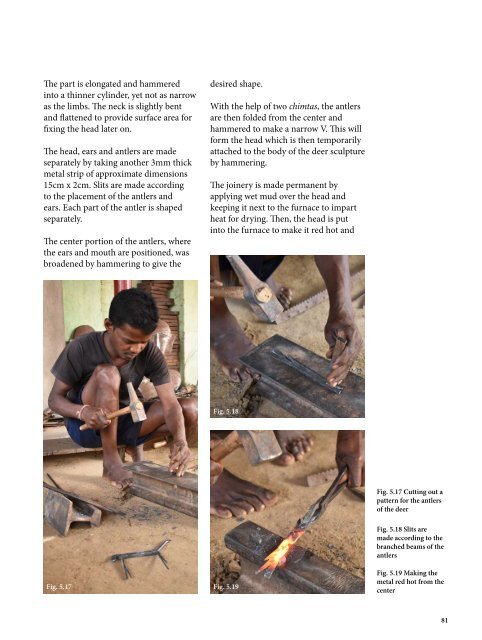

Fig. 5.17 Cutting out a<br />

pattern for the antlers<br />

of the deer<br />

Fig. 5.18 Slits are<br />

made according to the<br />

branched beams of the<br />

antlers<br />

Fig. 5.17 Fig. 5.19<br />

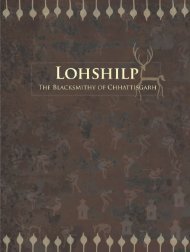

Fig. 5.19 Making the<br />

metal red hot from the<br />

center<br />

81