Issue 02/2019

Highlights: Thermoforming Building & Construction Basics: Biobased Packaging

Highlights:

Thermoforming

Building & Construction

Basics: Biobased Packaging

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Building & Construction<br />

Biocomposite made from<br />

sunflowers<br />

With the scientific expertise of the ENSIACET laboratory<br />

(Toulouse, France), Studio Thomas Vailly (Eindhoven,<br />

The Netherlands) investigated for Atelier Luma (Arles,<br />

France), the potential of sunflower leftovers to create novel<br />

applications. Focusing on the transformation of biobased matter,<br />

this project explores the potential of sunflower residues to create<br />

new applications and prototypes embedded in sustainable,<br />

innovative production systems. Such potential applications include<br />

for instance, panels for architectural designs (Fig. 1)<br />

Sunflowers are commonly farmed to produce oil, seeds or biofuel.<br />

After pressing the oil out, a part can be used as animal feed<br />

– the presscake - but most of the crop remains unused. The stalk’s<br />

foamy structure, the strong fibre of the bark or the flower’s dark<br />

brown proteins are left behind. These agro-wastes can be valuable<br />

resources to produce novel biomaterials.<br />

Based on scientific papers [1, 2, 3] a system of bio-materials<br />

using exclusively sunflower by-products has been investigated<br />

and designed. No petroleum based binder, no toxic varnish, all the<br />

necessary ingredients are extracted from the sunflower crop. The<br />

presscake – the remain of sunflower seed after the oil has been<br />

extracted - is turned into a waterbased glue and heat pressed into<br />

a thin and flexible film resembling leather (Fig. 2).<br />

Traditionnaly, only the flower head is harvested in late summer.<br />

However, the stalk of the plant can also be used. Harvested a<br />

month after the flower head, the bark–fibers can be separeted<br />

from the structural foamy marrow. The bark’s fibers are heat<br />

pressed into hardboard while the marrow is shaped into an<br />

aggregate, a natural alternative to polystyrene.<br />

These different bio-materials can be coated with a Sunflower<br />

varnish to enhance their resistance to water. The glue extracted<br />

from the seeds is the perfect adhesive to assemble these different<br />

materials. The Sunflower crop offers a unique range of bio-based<br />

and bio-degradable material. Entering the realm of bioplastics,<br />

a vast number of applications of what was previously considered<br />

waste becomes possible: from a tiny bolt to a large insulation<br />

panel, from a bio-board to a smartphone case. MT<br />

[1] Marechal, V. ; Rigal, L., 1999. Characterization of by-products of sunflower<br />

culture - commercial applications for stalks and heads. Industrial Crops and<br />

Products, 10 (3): 185-200<br />

[2] Evon, Philippe & Vandenbossche, Virginie & Pontalier, Pierre-Yves & Rigal,<br />

Luc. (2014). New thermal insulation fiberboards from cake generated during<br />

biorefinery of sunflower whole plant in a twin-screw extruder. Industrial Crops<br />

and Products. 52. 354-362. 10.1016/j.indcrop.2013.10.049.<br />

[3] Rouilly, Antoine & Mériaux, Alexandra & Geneau-Sbartaï, Céline & Silvestre,<br />

Françoise & Rigal, Luc. (2006). Film extrusion of sunflower protein isolate.<br />

Polymer Engineering and Science. 46. 10.10<strong>02</strong>/pen.20634.<br />

http://www.vailly.com/projects/sunflower-entreprise-/<br />

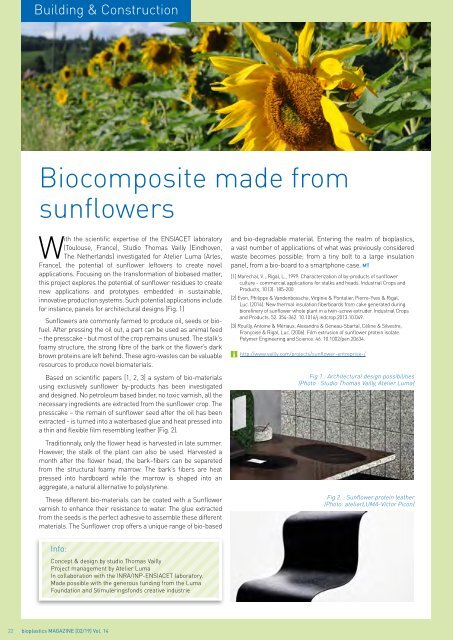

Fig 1 : Architectural design possibilities<br />

(Photo : Studio Thomas Vailly, Atelier Luma)<br />

Fig 2. : Sunflower protein leather<br />

(Photo: atelierLUMA-Victor Picon)<br />

Info:<br />

Concept & design by studio Thomas Vailly<br />

Project management by Atelier Luma<br />

In collaboration with the INRA/INP-ENSIACET laboratory.<br />

Made possible with the generous funding from the Luma<br />

Foundation and Stimuleringsfonds creative industrie<br />

22 bioplastics MAGAZINE [<strong>02</strong>/19] Vol. 14