Issue 01/2016

Automotive Foam Basics: Public Procurement

Automotive

Foam

Basics: Public Procurement

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Automotive<br />

with Francesca Brunori from Röchling Automotive. They<br />

presented their latest cooperation results on high heat PLA<br />

100% biobased natural fibre filled compounds with injection<br />

and compression moulding. The material is ready to use and<br />

Röchling is already in contact with different OEMs (see also<br />

page 15).<br />

Experts expect a growth in injection moulding for WPC and<br />

NFC: So far, also mainly small producers and traders were<br />

offering WPC and NFC granulates with a limited technical<br />

support and often missing data for simulations. But also<br />

this is changing since big global players are offering their<br />

new developed materials: “Sustainable Light weighting<br />

Thermoplastic Solutions for Automotives” (see also page<br />

12) was presented by Marc Mézailles from PolyOne Global<br />

Engineered Materials. This innovation from PolyOne breaks<br />

the conventional material property balance and opens<br />

the industrial use of natural fibres reinforced solutions in<br />

many demanding end applications and markets, including<br />

automotive, with a 5 to 10% light weighting potential vs.<br />

standard solutions. The material has a typical 30% fibre<br />

content, the fibre is an engineered industrial wood fibre, and<br />

a new coupling technology as well as a specific compounding<br />

process is used. PolyOne a first official OEM approval on a<br />

critical semi-structural application, and continues to be<br />

evaluated by several key OEMs and their Tier One suppliers.<br />

Today, as the last survey from nova-Institute showed,<br />

about 4 kg natural and wood fibres per vehicle in average<br />

are used European automotive production; but vehicles with<br />

considerably larger amounts of 20 kg natural and wood fibres<br />

have been successfully produced in series for years and could<br />

credit these amounts in the future.<br />

Most experts expect a continuously growth in the use of<br />

WPC and especially NFC in the automotive industry because<br />

of the high light weight potential of these materials, the<br />

continuously improvement of technologies and properties<br />

and new professional players. The combination with biobased<br />

polymers to realize fully biobased biocomposites is just<br />

starting and could become an additional market for biobased<br />

polymers such as PLA or PBS.<br />

www.nova-institute.com<br />

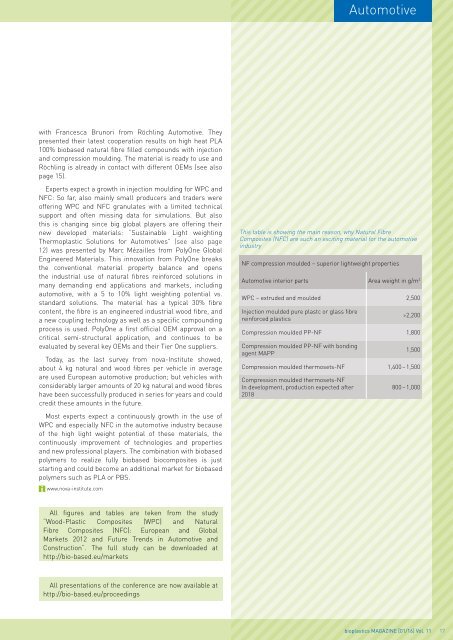

This table is showing the main reason, why Natural Fibre<br />

Composites (NFC) are such an exciting material for the automotive<br />

industry<br />

NF compression moulded – superior lightweight properties<br />

Automotive interior parts Area weight in g/m 2<br />

WPC – extruded and moulded 2,500<br />

Injection moulded pure plastc or glass fibre<br />

reinforced plastics<br />

>2,200<br />

Compression moulded PP-NF 1,800<br />

Compression moulded PP-NF with bonding<br />

agent MAPP<br />

1,500<br />

Compression moulded thermosets-NF 1,400 – 1,500<br />

Compression moulded thermosets-NF<br />

In development, production expected after<br />

2<strong>01</strong>8<br />

800 – 1,000<br />

All figures and tables are teken from the study<br />

“Wood-Plastic Composites (WPC) and Natural<br />

Fibre Composites (NFC): European and Global<br />

Markets 2<strong>01</strong>2 and Future Trends in Automotive and<br />

Construction“. The full study can be downloaded at<br />

http://bio-based.eu/markets<br />

All presentations of the conference are now available at<br />

http://bio-based.eu/proceedings<br />

bioplastics MAGAZINE [<strong>01</strong>/16] Vol. 11 17