- Page 1 and 2:

Quality. Safety. Performance. Catal

- Page 3 and 4:

General Information Contents 3 Coat

- Page 5 and 6:

General Information Product overvie

- Page 7 and 8:

General Information Machine pictogr

- Page 9 and 10:

Product guide Coated abrasives Page

- Page 11 and 12:

Product guide Coated abrasives Page

- Page 13 and 14:

Product guide Coated abrasives Page

- Page 15 and 16:

Coated abrasives Applications guide

- Page 17 and 18:

Coated abrasives Applications guide

- Page 19 and 20:

Rolls Application Type Grain Backin

- Page 21 and 22:

Rolls with paper backing Coated abr

- Page 23 and 24:

Rolls with cloth backing Coated abr

- Page 25 and 26:

Rolls with cloth backing Coated abr

- Page 27 and 28:

Rolls with cloth backing Coated abr

- Page 29 and 30:

Rolls with cloth backing Coated abr

- Page 31 and 32:

Rolls, non-woven web Non-woven web

- Page 33 and 34:

Rolls, foam Abrasive paper with foa

- Page 35 and 36:

Abrasive belts About the product Ap

- Page 37 and 38:

Abrasive belts Applications guide A

- Page 39 and 40:

Belts with paper backing Coated abr

- Page 41 and 42:

Belts with paper / film / cloth bac

- Page 43 and 44:

Belts with cloth backing Coated abr

- Page 45 and 46:

Belts with cloth backing Coated abr

- Page 47 and 48:

Belts with cloth backing Coated abr

- Page 49 and 50:

Belts with cloth backing Coated abr

- Page 51 and 52:

Belts with cloth backing Coated abr

- Page 53 and 54:

Belts with cloth backing Coated abr

- Page 55 and 56:

Belts with cloth backing Coated abr

- Page 57 and 58:

Belts with cloth backing Coated abr

- Page 59 and 60:

Belts with cloth backing Coated abr

- Page 61 and 62:

Belts with cloth backing Coated abr

- Page 63 and 64:

Belts with cloth backing Coated abr

- Page 65 and 66:

Belts with cloth backing Coated abr

- Page 67 and 68:

Belts with cloth backing Coated abr

- Page 69 and 70:

Belts with cloth backing Coated abr

- Page 71 and 72:

Non-woven web belts Non-woven web b

- Page 73 and 74:

Wide belts Applications guide Belt

- Page 75 and 76:

Wide belts with paper backing Coate

- Page 77 and 78:

Wide belts with paper backing Coate

- Page 79 and 80:

Wide belts with paper backing Coate

- Page 81 and 82:

Wide belts with cloth backing Coate

- Page 83 and 84:

Wide belts with cloth backing Coate

- Page 85 and 86:

Wide belts with cloth backing Coate

- Page 87 and 88:

Wide belts with cloth backing Coate

- Page 89 and 90:

Strips/Sheets/Discs About the produ

- Page 91 and 92:

Strips/Sheets/Discs Applications gu

- Page 93 and 94:

Sheets with paper backing Coated ab

- Page 95 and 96:

Sheets with paper backing Coated ab

- Page 97 and 98:

Sheets with paper backing Coated ab

- Page 99 and 100:

Sheets with paper backing Coated ab

- Page 101 and 102:

Strips with paper backing, self-fas

- Page 103 and 104:

Hand block Hand block HK 100 NEW !

- Page 105 and 106:

Sheets with cloth backing Coated ab

- Page 107 and 108:

Non-woven web hand pads Non-woven w

- Page 109 and 110:

Abrasive block Abrasive block, flex

- Page 111 and 112:

Abrasive sponge Abrasive sponge, fl

- Page 113 and 114:

Abrasive screen Abrasive screen, se

- Page 115 and 116:

Discs Applications guide Hole patte

- Page 117 and 118:

Discs with paper backing / Abrasive

- Page 119 and 120:

Discs with paper backing, self-fast

- Page 121 and 122:

Discs with paper backing, self-fast

- Page 123 and 124:

Discs with paper backing, self-fast

- Page 125 and 126:

Discs with paper backing, self-fast

- Page 127 and 128:

Discs with paper backing, self-fast

- Page 129 and 130:

Discs with paper backing, self-fast

- Page 131 and 132:

Discs with paper / film backing, se

- Page 133 and 134:

Discs with paper backing, self-fast

- Page 135 and 136:

Discs with paper backing, self-fast

- Page 137 and 138:

Back-up pads Coated abrasives Back-

- Page 139 and 140:

Discs with paper backing, self-fast

- Page 141 and 142:

Discs with cloth backing, self-adhe

- Page 143 and 144:

Discs, non-woven web Non-woven web

- Page 145 and 146:

Discs with foam backing Grinding di

- Page 147 and 148: Quick Change Discs About the produc

- Page 149 and 150: Quick Change Discs Applications gui

- Page 151 and 152: Quick Change Discs Quick Roll Conne

- Page 153 and 154: Quick Change Discs Quick Roll Conne

- Page 155 and 156: Quick Change Discs Quick Metal Conn

- Page 157 and 158: Quick Change Discs Quick Metal Conn

- Page 159 and 160: Quick Change Discs Quick Metal Conn

- Page 161 and 162: Quick Disc Connect Quick Disc Conne

- Page 163 and 164: Small abrasive mop About the produc

- Page 165 and 166: Small abrasive mop Abrasive mop Sma

- Page 167 and 168: Small abrasive mop Abrasive mop Co

- Page 169 and 170: Small abrasive mop Abrasive mop Sma

- Page 171 and 172: Notes Abrasive mop 171

- Page 173 and 174: Abrasive mop wheels Applications gu

- Page 175 and 176: Abrasive mop wheels Applications gu

- Page 177 and 178: Abrasive mop wheels Abrasive mop Ab

- Page 179 and 180: Abrasive mop wheels Abrasive mop Ab

- Page 181 and 182: Finishing mop Abrasive mop Abrasive

- Page 183 and 184: Abrasive flap drums Abrasive mop Sa

- Page 185 and 186: Abrasive flap drums / Adapter for s

- Page 187 and 188: Fibre discs About the product Kling

- Page 189 and 190: Fibre discs Coated abrasives Conti

- Page 191 and 192: Fibre discs Coated abrasives Abrasi

- Page 193 and 194: Fibre discs Coated abrasives Abrasi

- Page 195 and 196: Back-up pads / Dispenser Back-up pa

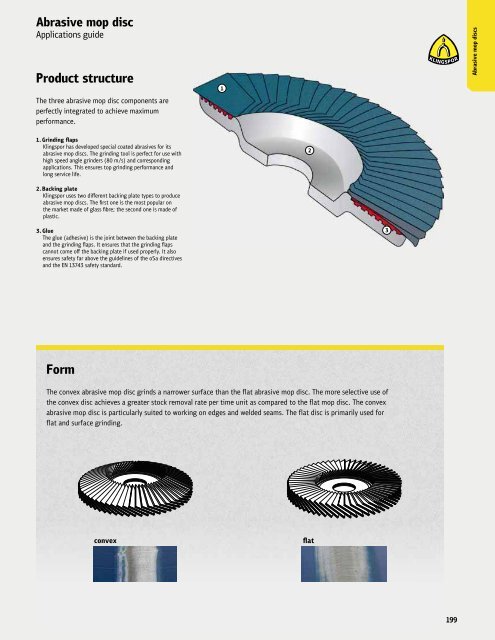

- Page 197: Abrasive mop disc About the product

- Page 201 and 202: Abrasive mop disc SMT programme Ste

- Page 203 and 204: Abrasive mop discs Abrasive mop dis

- Page 205 and 206: Abrasive mop discs Abrasive mop dis

- Page 207 and 208: Abrasive mop discs Abrasive mop dis

- Page 209 and 210: Abrasive mop discs Abrasive mop dis

- Page 211 and 212: Abrasive mop discs Abrasive mop dis

- Page 213 and 214: Abrasive mop discs Abrasive mop dis

- Page 215 and 216: High performance non-woven web whee

- Page 217 and 218: Abrasive mop discs Abrasive mop dis

- Page 219 and 220: Power Wheel Abrasive mop discs Powe

- Page 221 and 222: Kronenflex® cut-off wheels and gri

- Page 223 and 224: Kronenflex® cut-off wheels and gri

- Page 225 and 226: Kronenflex® cut-off wheels and gri

- Page 227 and 228: Kronenflex® cut-off wheels and gri

- Page 229 and 230: Kronenflex® cut-off wheels and gri

- Page 231 and 232: Kronenflex® large cut-off wheels A

- Page 233 and 234: Kronenflex® cut-off wheels for han

- Page 235 and 236: Kronenflex® cut-off wheels for han

- Page 237 and 238: Kronenflex® cut-off wheels for han

- Page 239 and 240: Kronenflex® cut-off wheels for han

- Page 241 and 242: Kronenflex® cut-off wheels for han

- Page 243 and 244: Kronenflex® small cut-off wheel fo

- Page 245 and 246: Kronenflex® large cut-off wheels f

- Page 247 and 248: Kronenflex® large cut-off wheels f

- Page 249 and 250:

Kronenflex® large cut-off wheels f

- Page 251 and 252:

Notes Cut-off wheels 251

- Page 253 and 254:

Kronenflex® grinding discs About t

- Page 255 and 256:

Kronenflex® grinding discs for han

- Page 257 and 258:

Kronenflex® grinding discs for han

- Page 259 and 260:

Kronenflex® grinding discs for han

- Page 261 and 262:

Kronenflex® cup grinding wheels fo

- Page 263 and 264:

Notes Grinding discs 263

- Page 265 and 266:

Diamond tools Remain in full contro

- Page 267 and 268:

Diamond tools Applications guide 1.

- Page 269 and 270:

Diamond tools Applications guide Nu

- Page 271 and 272:

Diamond cutting blades for angle gr

- Page 273 and 274:

Diamond cutting blades for angle gr

- Page 275 and 276:

Diamond cutting blades for angle gr

- Page 277 and 278:

Diamond cutting blades for angle gr

- Page 279 and 280:

Diamond cutting blades for angle gr

- Page 281 and 282:

Diamond cutting blades for angle gr

- Page 283 and 284:

Diamond cup grinding wheels for ang

- Page 285 and 286:

Diamond cup grinding wheels for ang

- Page 287 and 288:

Diamond cutting blades for petrol p

- Page 289 and 290:

Diamond cutting blades for table sa

- Page 291 and 292:

Diamond cutting blades for petrol p

- Page 293 and 294:

Diamond cutting blades for joint cu

- Page 295 and 296:

Diamond cutting blades for petrol p

- Page 297 and 298:

Diamond cutting blades for petrol p

- Page 299 and 300:

Reduction rings Reduction rings DZ

- Page 301 and 302:

Drill bit segments for DK 654 and D

- Page 303 and 304:

Hole starting aid Hole starting aid

- Page 305 and 306:

Flexible abrasives About the produc

- Page 307 and 308:

Flexible abrasives Mounted points,

- Page 309 and 310:

Flexible abrasives Hand block Hand

- Page 311 and 312:

Carbide burrs About the product Pow

- Page 313 and 314:

Carbide burrs Carbide burr SB-NF Ap

- Page 315 and 316:

Carbide burrs Carbide burr SC-DC Ap

- Page 317 and 318:

Carbide burrs Carbide burr SF-INOX

- Page 319 and 320:

Carbide burrs Carbide burr SG-DC Ap

- Page 321 and 322:

Carbide burrs Carbide burr SL-DC Ap

- Page 323 and 324:

D.I.Y. range The new Klingspor D.I.

- Page 325 and 326:

D.I.Y. range Continuation of LS 30

- Page 327 and 328:

D.I.Y. range Abrasive paper, waterp

- Page 329 and 330:

D.I.Y. range Abrasive paper, self-f

- Page 331 and 332:

D.I.Y. range Abrasive paper, self-f

- Page 333 and 334:

Safety recommendations Applications

- Page 335 and 336:

General Terms and Conditions of Tra

- Page 337 and 338:

Notes 337 Service

- Page 339 and 340:

Klingspor N.V. / S.A. Herent, Belgi