Catalogue 2020 - Canada

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

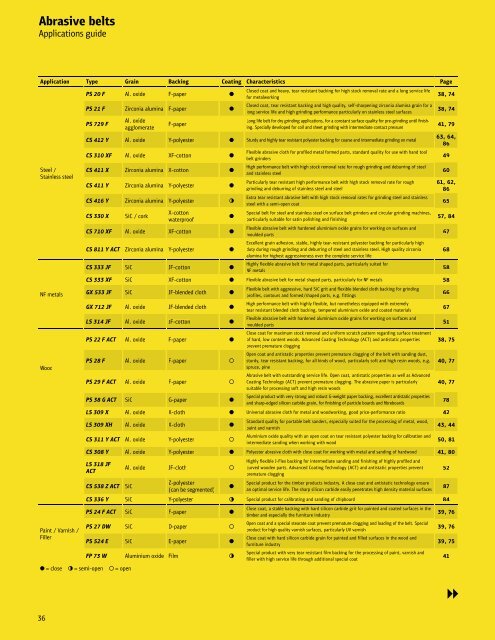

Abrasive belts<br />

Applications guide<br />

Application Type Grain Backing Coating Characteristics Page<br />

Steel /<br />

Stainless steel<br />

NF metals<br />

Wood<br />

Paint / Varnish /<br />

Filler<br />

PS 20 F Al. oxide F-paper J<br />

PS 21 F Zirconia alumina F-paper J<br />

PS 729 F<br />

Al. oxide<br />

agglomerate<br />

F-paper<br />

Closed coat and heavy, tear resistant backing for high stock removal rate and a long service life<br />

for metalworking<br />

Closed coat, tear resistant backing and high quality, self-sharpening zirconia alumina grain for a<br />

long service life and high grinding performance particularly on stainless steel surfaces<br />

Long life belt for dry grinding applications, for a constant surface quality for pre-grinding until finishing.<br />

Specially developed for coil and sheet grinding with intermediate contact pressure<br />

CS 412 Y Al. oxide Y-polyester J Sturdy and highly tear resistant polyester backing for coarse and intermediate grinding on metal<br />

CS 310 XF Al. oxide XF-cotton J<br />

CS 411 X Zirconia alumina X-cotton J<br />

CS 411 Y Zirconia alumina Y-polyester J<br />

CS 416 Y Zirconia alumina Y-polyester K<br />

CS 330 X<br />

SiC / cork<br />

X-cotton<br />

waterproof<br />

CS 710 XF Al. oxide XF-cotton J<br />

CS 811 Y ACT Zirconia alumina Y-polyester J<br />

CS 333 JF SiC JF-cotton J<br />

J<br />

Flexible abrasive cloth for profiled metal formed parts, standard quality for use with hand tool<br />

belt grinders<br />

High performance belt with high stock removal rate for rough grinding and deburring of steel<br />

and stainless steel<br />

Particularly tear resistant high performance belt with high stock removal rate for rough<br />

grinding and deburring of stainless steel and steel<br />

Extra tear resistant abrasive belt with high stock removal rates for grinding steel and stainless<br />

steel with a semi-open coat<br />

Special belt for steel and stainless steel on surface belt grinders and circular grinding machines,<br />

particularly suitable for satin polishing and finishing<br />

Flexible abrasive belt with hardened aluminium oxide grains for working on surfaces and<br />

moulded parts<br />

Excellent grain adhesion, stable, highly tear-resistant polyester backing for particularly high<br />

duty during rough grinding and deburring of steel and stainless steel. High quality zirconia<br />

alumina for highest aggressiveness over the complete service life<br />

Highly flexible abrasive belt for metal shaped parts, particularly suited for<br />

NF metals<br />

CS 333 XF SiC XF-cotton J Flexible abrasive belt for metal shaped parts, particularly for NF metals 58<br />

GX 533 JF SiC JF-blended cloth J<br />

GX 712 JF Al. oxide JF-blended cloth J<br />

LS 314 JF Al. oxide JF-cotton J<br />

PS 22 F ACT Al. oxide F-paper J<br />

PS 28 F Al. oxide F-paper I<br />

PS 29 F ACT Al. oxide F-paper I<br />

PS 38 G ACT SiC G-paper J<br />

Flexible belt with aggressive, hard SiC grit and flexible blended cloth backing for grinding<br />

profiles, contours and formed/shaped parts, e.g. fittings<br />

High performance belt with highly flexible, but nonetheless equipped with extremely<br />

tear resistant blended cloth backing, tempered aluminium oxide and coated materials<br />

Flexible abrasive belt with hardened aluminium oxide grains for working on surfaces and<br />

moulded parts<br />

Close coat for maximum stock removal and uniform scratch pattern regarding surface treatment<br />

of hard, low content woods. Advanced Coating Technology (ACT) and antistatic properties<br />

prevent premature clogging<br />

Open coat and antistatic properties prevent premature clogging of the belt with sanding dust,<br />

sturdy, tear resistant backing, for all kinds of wood, particularly soft and high resin woods, e.g.<br />

spruce, pine<br />

Abrasive belt with outstanding service life. Open coat, antistatic properties as well as Advanced<br />

Coating Technology (ACT) prevent premature clogging. The abrasive paper is particularly<br />

suitable for processing soft and high resin woods<br />

Special product with very strong and robust G-weight paper backing, excellent antistatic properties<br />

and sharp-edged silicon carbide grain, for finishing of particle boards and fibreboards<br />

LS 309 X Al. oxide X-cloth J Universal abrasive cloth for metal and woodworking, good price-performance ratio 42<br />

LS 309 XH Al. oxide X-cloth J<br />

CS 311 Y ACT Al. oxide Y-polyester I<br />

Standard quality for portable belt sanders, especially suited for the processing of metal, wood,<br />

paint and varnish<br />

Aluminium oxide quality with an open coat on tear resistant polyester backing for calibration and<br />

intermediate sanding when working with wood<br />

CS 308 Y Al. oxide Y-polyester J Polyester abrasive cloth with close coat for working with metal and sanding of hardwood 41, 80<br />

LS 318 JF<br />

ACT<br />

CS 538 Z ACT<br />

Al. oxide JF-cloth I<br />

SiC<br />

J = close K = semi-open I = open<br />

Z-polyester<br />

(can be segmented)<br />

J<br />

Highly flexible J-Flex backing for intermediate sanding and finishing of highly profiled and<br />

curved wooden parts. Advanced Coating Technology (ACT) and antistatic properties prevent<br />

premature clogging<br />

Special product for the timber products industry. A close coat and antistatic technology ensure<br />

an optimal service life. The sharp silicon carbide easily penetrates high density material surfaces<br />

CS 336 Y SiC Y-polyester K Special product for calibrating and sanding of chipboard 84<br />

PS 24 F ACT SiC F-paper J<br />

PS 27 DW SiC D-paper I<br />

PS 524 E SiC E-paper J<br />

FP 73 W Aluminium oxide Film K<br />

Close coat, a stable backing with hard silicon carbide grit for painted and coated surfaces in the<br />

timber and especially the furniture industry<br />

Open coat and a special stearate coat prevent premature clogging and loading of the belt. Special<br />

product for high quality varnish surfaces, particularly UV varnish<br />

Close coat with hard silicon carbide grain for painted and filled surfaces in the wood and<br />

furniture industry<br />

Special product with very tear resistant film backing for the processing of paint, varnish and<br />

filler with high service life through additional special coat<br />

38, 74<br />

38, 74<br />

41, 79<br />

63, 64,<br />

86<br />

49<br />

60<br />

61, 62,<br />

86<br />

65<br />

57, 84<br />

67<br />

68<br />

58<br />

66<br />

67<br />

51<br />

38, 75<br />

40, 77<br />

40, 77<br />

78<br />

43, 44<br />

50, 81<br />

52<br />

87<br />

39, 76<br />

39, 76<br />

39, 75<br />

41<br />

36