Protection of Fuel Tanks Safety ahead! - GL Group

Protection of Fuel Tanks Safety ahead! - GL Group

Protection of Fuel Tanks Safety ahead! - GL Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

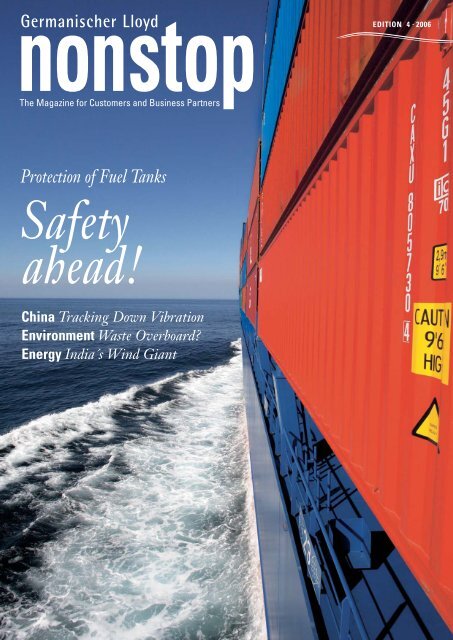

The Magazine for Customers and Business Partners<br />

<strong>Protection</strong> <strong>of</strong> <strong>Fuel</strong> <strong>Tanks</strong><br />

<strong>Safety</strong><br />

<strong>ahead</strong>!<br />

China Tracking Down Vibration<br />

Environment Waste Overboard?<br />

Energy India´s Wind Giant<br />

EDITION 4 • 2006

Six thousand times thank you!<br />

Six thousand ships with <strong>GL</strong> class.<br />

Germanischer Lloyd Aktiengesellschaft<br />

Vorsetzen 35 · 20459 Hamburg/Germany<br />

Phone: +49 40 36149-0 · Fax: +49 40 36149-200<br />

head<strong>of</strong>fice@gl-group.com · www.gl-group.com<br />

Six thousand ships with about 60 million GT are now on course with <strong>GL</strong> class! This is a<br />

wonderful occasion to thank our customers for their trust and cooperation in the spirit<br />

<strong>of</strong> partnership. At the same time this milestone is a great incentive for us to continue<br />

our successful growth and to keep <strong>of</strong>fering our customers first-class service.

Dear Readers,<br />

The year 2006 will be ending in just a few weeks. Perhaps<br />

it is a bit too early to draw any final conclusions just yet.<br />

But there can already be no doubt that Germanischer<br />

Lloyd will once again be able to present impressive<br />

growth figures. During the first three quarters alone,<br />

Maritime Services sales increased by 11 % while Industrial<br />

Services sales grew by as much as 34 %. We are<br />

especially happy about the rising number <strong>of</strong> newbuilding<br />

orders for tankers and bulk carriers. In particular,<br />

we have been able to boost tanker classification orders<br />

by almost two million GT, demonstrating that our<br />

corporate expansion strategy is on the right track.<br />

Despite vigorous competition, we successfully defended<br />

our market share in the classification <strong>of</strong> container vessels.<br />

In October 2006, we received the highest number<br />

<strong>of</strong> orders this year, and the second highest in our com- Rainer Schöndube<br />

pany’s entire history <strong>of</strong> 139 years. A special highlight in<br />

November was the world’s first-ever order for the classification<br />

<strong>of</strong> submarines, specifically three vessels from German production for the South<br />

African Navy. Our innovative submarine engineering rules, first published in February 2005,<br />

underscore our comprehensive technological expertise. Germanischer Lloyd is the only<br />

classification society <strong>of</strong>fering such a service. Our maritime safety philosophy <strong>of</strong> maximizing<br />

precaution while ensuring economic feasibility remains as compelling as ever. New international<br />

regulations for the protection <strong>of</strong> fuel oil tanks were introduced recently. Our engineers<br />

show how doing a few extra calculations can be most worthwhile in finding the optimum tank<br />

arrangement. To learn how helpful this is, please read our lead article.<br />

Success makes attractive. The shareholders <strong>of</strong> Germanischer Lloyd are being ardently courted<br />

at the moment. While we perceive these renewed advances as clear appreciation <strong>of</strong> our excellent<br />

performance, there should be no misconceptions about the origin <strong>of</strong> our success. Indeed,<br />

it is the result <strong>of</strong> the hard work <strong>of</strong> our loyal employees, who are dedicated to providing excellent<br />

service to the customers <strong>of</strong> our Society. “Operating 24/7” is not only our credo but also<br />

the first-class principle <strong>of</strong> continued commitment to quality, safety and economic efficiency.<br />

We will continue to be there to <strong>of</strong>fer you outstanding service. You have my word on that.<br />

Yours sincerely,<br />

Das Besondere<br />

ist unsere Stärke<br />

Rainer Schöndube<br />

Member <strong>of</strong> the Executive Board<br />

EDITORIAL<br />

nonstop 4/2006<br />

3

CONTENTS<br />

IMPRINT<br />

12<br />

<strong>Safety</strong>:<br />

<strong>Fuel</strong> Tank<br />

<strong>Protection</strong><br />

16<br />

Interview:<br />

EMSA Executive<br />

de Ruiter<br />

24<br />

<strong>GL</strong> Pegasus:<br />

The S<strong>of</strong>tware<br />

that Tells<br />

40<br />

Wind Energy:<br />

India’s<br />

Market<br />

Leader<br />

COVERSTORY<br />

12 <strong>Fuel</strong> Tank <strong>Protection</strong>: <strong>Safety</strong> Ahead!<br />

MARITIME SERVICES<br />

5 News<br />

11 CD-ROM: The New <strong>GL</strong> ShipManager<br />

16 “Safer than in the Past” – Interview EMSA Executive de Ruiter<br />

19 <strong>GL</strong> Vent: Cool Transport<br />

20 Emergency Response Service: SOS at 0. 30 a.m.<br />

23 Shiplifting: Fluids in Motion<br />

24 <strong>GL</strong> Pegasus: Checking Steel in Style<br />

26 Union Transport: From Basel to Bromley<br />

29 “Quality is Non-Negotiable” – Interview Dr Wasmansdorff<br />

30 China: Tracking Down Vibration<br />

32 Waste Management: Waste Overboard?<br />

36 VDMA: Goals for the Future<br />

INDUSTRIAL SERVICES<br />

38 News<br />

40 India: Lord <strong>of</strong> the Wind – Interview Suzlon CEO Tanti<br />

43 Poland: Just a Stamp Won’t Do<br />

44 Pipelines: Smart Pigs on a Mission<br />

STANDARDS<br />

46 Perspectives – Review: Plimsoll’s Lifeline<br />

47 New Directions – <strong>GL</strong> Academy<br />

48 Addresses: Headquarters and Divisions<br />

nonstop Issue no. 4/2006, Dec. 2006 Circulation nonstop is published four times a year with a print run <strong>of</strong> 9,500 copies in German and 11,500 in English Published by<br />

Germanischer Lloyd Aktiengesellschaft, Hamburg Editorial Director Dr Olaf Mager, Press and Information Managing Editor Steffi Gößling Authors <strong>of</strong> this issue Steffen Brauer<br />

(SB), Hendrik Bruhns (HB), Ould El Moctar (OEM), Christian Göldenboog (CG), Anne Güldenpfennig (AG), Jürgen Helm (JH), Christoph Hinz (CH), Jörn Iken (JI), Atanaska<br />

Kostadinova (AK), Nora Luttmer (NL), Jens Meyer (JM), Stefanie Normann (SN), Nina Pauls (NP), Barbara Sommerh<strong>of</strong>f (BS), Jasmin Straube (JS) Design and Production<br />

printprojekt, Schulterblatt 58, 20357 Hamburg, Germany Layout Oliver Lohrengel Prepress Fire Department Printed by K.O. Storck & Co. Subscription Service This magazine<br />

can be obtained from pr@gl-group.com Reprint © Germanischer Lloyd Aktiengesellschaft 2006. Reprinting permitted – copy requested. All information is correct to the best<br />

<strong>of</strong> our knowledge. Contributions by external authors do not necessarily reflect the views <strong>of</strong> the editors or <strong>of</strong> Germanischer Lloyd. Enquiries to: Germanischer Lloyd AG, Press<br />

and Information, Vorsetzen 35, 20459 Hamburg, Germany, Phone: +49 40 36149-4509, Fax: +49 40 36149-250, E-Mail: pr@gl-group.com<br />

4 nonstop 4/2006<br />

Photo: Eberhardt Petzold (Cover)

News from the Maritime Services<br />

ECONOMIC ADVISORY COMMITTEE<br />

News from Panama<br />

AFrench competitor’s takeover attempt<br />

was among the many topics.<br />

Following <strong>GL</strong> Board Member Rainer<br />

Schöndube’s detailed report on the<br />

business situation <strong>of</strong> the enterprise,<br />

the participants at the second annual<br />

meeting <strong>of</strong> the Economic Advisory<br />

Committee briefly discussed the BV<br />

takeover <strong>of</strong>fer. Several representatives<br />

<strong>of</strong> shipown-ing companies threatened<br />

to change classes in the event that<br />

Germanischer Lloyd’s high safety and<br />

quality standards were to be compromised.<br />

The full agenda prevented a more<br />

extensive discussion. Dr Hermann J.<br />

Klein explained the upcoming changes<br />

affecting Panmax ship sizes. Following<br />

the enlargement <strong>of</strong> the Panama Canal,<br />

larger Panmax-type container vessels<br />

will be able to use this major transit<br />

route from the year 2014 onwards.<br />

The dimensions <strong>of</strong> the new ship<br />

type will be matched to the width <strong>of</strong><br />

the locks. These will be 427 m long, 55<br />

m wide, and 18.3 m deep. Dr Klein introduced<br />

a new, innovative container<br />

ship design adapted to the new canal<br />

dimensions – 398 m long, 54.2 m wide<br />

and 27.7 m tall, capable <strong>of</strong> carrying<br />

14,000 standard containers. The new<br />

regulation on the protection <strong>of</strong> fuel<br />

oil bunkers, effective for ships with<br />

keels laid on or after 1 February 2008,<br />

have been incorporated in the design<br />

<strong>of</strong> these vessels (refer to our lead story<br />

on p. 12).<br />

Yacht design. A speech that met with<br />

particular interest was the lecture by<br />

TAKEOVER OFFER<br />

Vive la Différence<br />

Germanischer Lloyd AG’s management<br />

and supervisory board have<br />

recommended that their shareholders<br />

reject the takeover <strong>of</strong>fer <strong>of</strong> Bureau<br />

Veritas. It is neither adequate for the<br />

Photo: judel/vrolijk & co<br />

REGATTA YACHT. Design makes the difference.<br />

Torsten Conradi, general manager <strong>of</strong><br />

judel/vrolijk & co engineering gmbh,<br />

on the topic: “What are the Characteristics<br />

<strong>of</strong> Successful Regatta and Series<br />

Yachts?” His engineering company, active<br />

internationally, has been designing<br />

sail and motor yachts since 1978.<br />

With its first series yacht, named “Popcorn”,<br />

judel/vrolijk & co firmly established<br />

their name in the regatta world.<br />

Their designs have earned numerous<br />

titles in international competitions,<br />

among them nine Admiral’s<br />

society and its 3,200 members, nor is<br />

it in the shareholders’ best interest.<br />

Upon reviewing and evaluating the <strong>of</strong>fer,<br />

a mutual statement was prepared,<br />

explaining to the 50 shareholders the<br />

NEWS | MARITIME SERVICES<br />

Cups, the un<strong>of</strong>ficial team ocean racing<br />

world championship. Apart from racing<br />

yachts, the company has also become<br />

a leader in the design <strong>of</strong> cruising<br />

yachts.<br />

As with all sports disciplines, it is<br />

not just the material used that makes<br />

the difference. The hull, the sails, the<br />

rigging, the trim – they all figure in the<br />

equation, as do the preparation logistics,<br />

the sailing tactics, and the team’s<br />

pr<strong>of</strong>essionalism.<br />

www.judel-vrolijk.com<br />

grounds for declining the <strong>of</strong>fer. The<br />

statement clearly refl ects the unanimous<br />

disapproval <strong>of</strong> the <strong>of</strong>fer by the<br />

management team, the supervisory<br />

board and the employees.<br />

nonstop 4/2006<br />

5

MARITIME SERVICES | NEWS<br />

MARKET STUDY<br />

Shipbuilding Boom<br />

Continues<br />

The recent shipbuilding market study<br />

by HypoVereinsbank, Hamburg,<br />

leaves no room for doubt. Shipyards<br />

and suppliers can expect to be working<br />

at their limits for years to come,<br />

while market prices will reach record<br />

levels.<br />

For over three years, the world’s<br />

shipbuilding industry has been enjoying<br />

its most persistent and vigorous<br />

high tide ever. On 1 August 2006, there<br />

were 5,386 ships on order worldwide<br />

with a total tonnage <strong>of</strong> 269.1 million<br />

dwt (an international unit <strong>of</strong> measure<br />

for ship sizes), or 117.4 million CGT<br />

(another international unit <strong>of</strong> measure<br />

for ships), and a total ordered value <strong>of</strong><br />

US$ 263.9 billion.<br />

The situation looks bright for German<br />

shipbuilders. German shipyards<br />

STG GENERAL ASSEMBLY<br />

The Need for a Long-term Perspective<br />

Whatever the reason, the opening<br />

night <strong>of</strong> this year’s annual<br />

meeting <strong>of</strong> the Schiffbautechnische<br />

Gesellschaft, Germany’s time-honoured<br />

Society for Maritime Technology,<br />

at Hotel Hafen Hamburg was<br />

unusually crowded. STG honorary<br />

member Bernhard Meyer, owner <strong>of</strong><br />

the Meyer Werft shipyard in Papenburg,<br />

enlightened the audience on<br />

the strengths and opportunities <strong>of</strong><br />

the German shipbuilding industry.<br />

Referring to the current high level <strong>of</strong><br />

incoming orders, he used the steel,<br />

copper and nickel markets as examples<br />

to illustrate the exotic world<br />

<strong>of</strong> pricing, showing how difficult it<br />

can be to make sound price calcula-<br />

ADMONISHION. Shipbuilder<br />

Bernhard Meyer discussing the<br />

future <strong>of</strong> the industry.<br />

6 nonstop 4/2006<br />

Photo: Bogumil<br />

THE LAUNCH. Newly-built<br />

vessel by tanker specialist<br />

Lindenau-Werft.<br />

are currently pr<strong>of</strong>iting from a boom in<br />

the container and specialty ship sectors<br />

where Far-Eastern shipyards are<br />

unable to meet the current demand so<br />

orders have been rerouted to Europe.<br />

Innovative power. By collaborating<br />

more closely, European shipbuilders<br />

could position themselves even better.<br />

German shipbuilders in particular,<br />

tions in a high-demand situation.<br />

The high-end luxury yacht and<br />

cruise ship sector will <strong>of</strong>fer shipbuilders<br />

attractive opportunities<br />

during the next ten years. Continued<br />

product innovation and further<br />

improvements to the industry’s internal<br />

structure are prerequisites for<br />

translating opportunities into business<br />

success. Collaboration in research<br />

projects in the areas <strong>of</strong> manufacturing<br />

and logistics could generate<br />

competitive advantages. Cooperative<br />

purchasing on a national and<br />

international level will save costs.<br />

Competition from Asia. Citing deficits<br />

in engineer training, Meyer called<br />

upon the government to step up its<br />

support for education. He also criticized<br />

the high social security contributions<br />

as a factor compromising international<br />

competitiveness.<br />

The high cost <strong>of</strong> labour, he said, is<br />

just as problematic for shipbuilders<br />

as the excessive bureaucracy. He particularly<br />

referred to current tax legislation<br />

levying taxes on the common<br />

practice <strong>of</strong> interim financing <strong>of</strong> newbuildings.<br />

Urging the political decision-makers<br />

not to underestimate<br />

the long-term aspirations <strong>of</strong> the<br />

great Asian nations, he said: “They<br />

want to achieve something. They<br />

want to participate in our wealth.”<br />

as well as the world-leading German<br />

supply industry, should further leverage<br />

their innovative potential: leadingedge<br />

ship design, superior quality and<br />

innovation, reliable delivery timing,<br />

and flexibility will be key parameters<br />

for competing successfully in the international<br />

marketplace.<br />

ORDERBOOK<br />

New Record in<br />

October<br />

PRESENTATION.<br />

<strong>GL</strong> Executive<br />

Rainer Schöndube.<br />

Classification orders for more<br />

than 100 newbuildings with a<br />

total GTI number <strong>of</strong> 2.1 million<br />

set the monthly record in orders<br />

received for 2006, topping the<br />

total volume <strong>of</strong> the year 1995. By<br />

the end <strong>of</strong> October, orders totalled<br />

1,116 ships with a joint GTI <strong>of</strong> 19.6<br />

million. “Based on our current orders<br />

on hand, we expect 2006 to be<br />

another year with a double-digit<br />

growth rate,” said Germanischer<br />

Lloyd Board <strong>of</strong> Executives Member<br />

Rainer Schöndube.<br />

Photo: Bogumil

VIETNAM<br />

Two New Offi ces<br />

November was a busy month: Vietnam<br />

became a member <strong>of</strong> the<br />

World Trade Organization (WTO);<br />

the trade fair “Maritime Vietnam”<br />

showcased the growing importance<br />

<strong>of</strong> shipbuilding and the supply industry;<br />

and Germanischer Lloyd <strong>of</strong>ficially<br />

opened its new <strong>of</strong>fi ces in Hanoi<br />

and Haiphong. Le Thanh Binh,<br />

Germanischer Lloyd Country Manager<br />

for Vietnam, welcomed more<br />

than 60 guests from the country’s<br />

administration, the shipyard industry<br />

and shipowning companies<br />

to the opening ceremony in Hanoi.<br />

<strong>GL</strong> opened its fi rst branch <strong>of</strong>fi ce<br />

in early 1995 in Ho Chi Minh City. To-<br />

PARTY TIME. Dang Thanh Quang (left) and<br />

Huynh Hong Vu (right) congratulate Le Thanh<br />

Binh and Dr Volkmar Wasmansdorff (<strong>GL</strong>).<br />

SHIPBUILDING<br />

German Shipyard Orders – Totalling<br />

US$ 33.5 billion<br />

At the end <strong>of</strong> the third quarter 2006,<br />

5,386 ships were on order with<br />

shipyards worldwide, ordered by 770<br />

ship-owners from 61 countries. The<br />

orders-per-country list is headed by<br />

shipowners from Japan and Germany,<br />

totalling US$ 36.9 billion and US$<br />

33.5 billion, respectively, followed by<br />

day, close to 30 container ships and<br />

multi-purpose vessels under construction<br />

in Vietnamese shipyards<br />

for Vietnamese, German and Danish<br />

owners are up for classifi cation by<br />

Germanischer Lloyd. Even the local<br />

supply industry uses <strong>GL</strong> certifi cation<br />

services for equipment such as boilers<br />

or welding consumables.<br />

the USA. (US$ 21.4 billion), Greece<br />

(US$ 18.8 billion), and Norway (US$<br />

16.5 billion). According to Clarkson<br />

Research, the high investment volume<br />

in Germany is largely attributable to<br />

the German limited partnership (KG)<br />

model that facilitates access to private<br />

capital.<br />

Germanischer Lloyd Supervisory Board Visits China<br />

The Chinese shipbuilding industry keeps growing. The members <strong>of</strong> the Germanischer Lloyd Supervisory Board could see this for<br />

themselves during a joint trip to China in September. In Guangzhou, <strong>GL</strong> Executive Board Member Rainer Schöndube (seated, 2nd<br />

from the right) and Yiu Xueming (seated, second from the left), General Manager <strong>of</strong> Guangzhou Wenchong Shipyard, signed a<br />

<strong>GL</strong>-classifi cation agreement for twelve 1740 TEU container vessels.<br />

ASIA<br />

NEWS | MARITIME SERVICES<br />

FAREWELL.<br />

SDARI manager Hu Jintao<br />

and Hergen Thielemann.<br />

Thielemann Retiring<br />

Before I close a business deal, I<br />

want to get to know my business<br />

partners personally.” This was<br />

Hergen Thielemann’s approach<br />

to winning customers throughout<br />

the Asian continent, said Dr Hermann<br />

J. Klein in his eulogy during<br />

Mr Thielemann’s farewell ceremony<br />

in Shanghai last October.<br />

Thielemann leaves Germanischer<br />

Lloyd after nearly 29 years<br />

<strong>of</strong> service in 14 countries. His last<br />

position was that <strong>of</strong> East Asian<br />

Division Manager, based in Singapore<br />

and Shanghai. Life in Asia<br />

is not always easy for a European,<br />

said Hu Jintao, President <strong>of</strong> naval<br />

engineering company SDARI. “You<br />

managed with sincerity and a good<br />

sense <strong>of</strong> humour. We will always remember<br />

you with fondness.”<br />

nonstop 4/2006<br />

7

MARITIME SERVICES | NEWS<br />

LECTURE<br />

Taming the Monster Waves<br />

The event at the great hall <strong>of</strong> the<br />

Hamburg Ship Model Basin (HSVA)<br />

was better attended than some <strong>of</strong> his<br />

university lectures, said Günther F.<br />

Clauss, winking, as he began the 29th<br />

Georg Weinblum Memorial Lecture.<br />

150 engineers had come to listen to<br />

Clauss, a pr<strong>of</strong>essor at the Berlin Technical<br />

University’s Institute <strong>of</strong> Naval<br />

and Maritime Technology. The title <strong>of</strong><br />

his speech: „The Taming <strong>of</strong> the Shrew<br />

– Tailoring Freak Wave Sequences for<br />

Seakeeping Tests.“<br />

„What is a monster wave?“ asked<br />

Clauss, introducing an evasive <strong>of</strong> topic<br />

to his audience. The existence such<br />

extreme waves, characterized by an<br />

enormous height, is hard to prove. A<br />

LOBBYIST.<br />

Dr Mary Papaschinopoulou.<br />

<strong>GL</strong> EXCHANGE FORUM<br />

Trained for Ice<br />

PAPENBURG<br />

few occurrences have been registered<br />

by <strong>of</strong>fshore research platforms. „But<br />

monster waves are not as rare as you<br />

might think,“ said Clauss. His goal is<br />

to put some figures on the seemingly<br />

incalculable phenomenon. As a result<br />

<strong>of</strong> his research, freak waves can now<br />

be described through mathematical<br />

models, and simulated in wave channels.<br />

Their effects on ship models can<br />

be tested under realistic conditions.<br />

Clauss envisions computer programs<br />

capable <strong>of</strong> anticipating monster<br />

waves. One day, CASH (Computer Aided<br />

Ship Handling) systems will hopefully<br />

deliver information on an imminent<br />

natural event previously considered<br />

unpredictable. Germanischer<br />

What Counts in Brussels?<br />

Leverage your contacts proactively! This is<br />

your only chance to make your ideas be<br />

heard!“ A piece <strong>of</strong> advice given by Dr Mary<br />

Papaschinopoulou to an audience <strong>of</strong> 220<br />

guests invited by Germanischer Lloyd to<br />

the Old Papenburg Shipyard.<br />

Papaschinopoulou heads the Brussels<br />

<strong>of</strong>fi ce <strong>of</strong> the Northern German Chamber <strong>of</strong><br />

Commerce and represents the interests <strong>of</strong><br />

Germanischer Lloyd with European Union<br />

What kinds <strong>of</strong> problems can ships encounter in icy seas?<br />

How can damages be prevented? At the recent <strong>GL</strong> Exchange<br />

Forum “Operating in Ice”, three Finnish experts educated<br />

their audience <strong>of</strong> 80 about the hazards <strong>of</strong> navigating<br />

through a frozen Baltic. They agreed that many propeller<br />

and rudder damages are caused by inexperienced crews.<br />

Collisions frequently occur between a ship and its icebreaker<br />

or between several ships <strong>of</strong> a convoy. Cracks, holes<br />

or damaged superstructures are <strong>of</strong>ten the consequences,<br />

said Seppo Liukkonen, Germanischer Lloyd’s Helsinki Station<br />

Manager.<br />

Navigating ice. But how can you prevent such accidents?<br />

Deltamarin Contracting LTD is currently developing specialized<br />

ice navigation training programmes. Expert Kimmo<br />

Juurma promised: “The first pilot project will be launched<br />

soon.” Captain Atso Uusiaho <strong>of</strong> Finnish icebreaker operator<br />

Finstaship is looking forward to its implementation: “So<br />

far, the only way to learn was trial and error.”<br />

For further information: Seppo Liukkonen, Station Manager Helsinki,<br />

Phone: +358 9 6850750, E-Mail: seppo.liukkonen@gl-group.com<br />

8 nonstop 4/2006<br />

EXPERT.<br />

Pr<strong>of</strong>. Günther<br />

F. Clauss.<br />

Lloyd is actively supporting this development<br />

project.<br />

Memorial Lecture:<br />

The Georg Weinblum Memorial Endowment<br />

was established in 1978 in<br />

Germany and the USA in memory <strong>of</strong><br />

Georg P. Weinblum, an internationally<br />

renowned naval scientist. Once every<br />

year, an internationally respected naval<br />

hydrodynamics expert gives a lecture<br />

to support international cooperation<br />

in this fi eld as fostered by Weinblum.<br />

agencies. In her speech, she emphasized Europe’s<br />

role as a focal point <strong>of</strong> maritime trade:<br />

40% <strong>of</strong> the world’s trade fl eet is Europeanowned,<br />

and 80% <strong>of</strong> EU imports and exports<br />

pass through the Union‘s seaports. “2007 will<br />

be an interesting, trend-setting year for maritime<br />

trade,” said Dr Papaschinopoulou. Key<br />

items on the agenda are the Third Maritime<br />

<strong>Safety</strong> Package, and the Green Book defi ning<br />

a common European maritime policy.<br />

ICE TRIP.<br />

Many crews lack<br />

experience.

MILESTONES<br />

New Agreement<br />

Hapag-Lloyd and Germanischer<br />

Lloyd have signed an agreement<br />

on classification and flag-state servicing<br />

<strong>of</strong> <strong>GL</strong>-classed ships. “This agreement<br />

is a milestone in the longstanding<br />

partnership between Hapag-<br />

Lloyd and Germanischer Lloyd” said<br />

Germanischer Lloyd executive Dr<br />

Hermann J. Klein. With an initial term<br />

<strong>of</strong> five years, the agreement covers all<br />

<strong>of</strong> Hapag-Lloyd’s newbuilt ships classified<br />

by Germanischer Lloyd. The<br />

innovative stipulations <strong>of</strong> the agreement<br />

significantly reduce administrative<br />

effort.<br />

Perspective. “This agreement reinforces<br />

the existing relationship <strong>of</strong> trust<br />

and the mutual commitment to close<br />

cooperation for years to come,” said<br />

Hapag-Lloyd executive Adolf Adrion.<br />

MUTUAL TRUST. Executives<br />

Dr Klein (<strong>GL</strong>) and Adrion (Hapag-Lloyd).<br />

DECEMBER<br />

07.12.2006<br />

<strong>GL</strong> Container Forum 2006<br />

Hamburg, Germany<br />

JANUARY<br />

20.01. – 28.01.2007<br />

Boot<br />

Düsseldorf, Germany<br />

24.01. – 25.01.2007<br />

6th Conference <strong>of</strong> Corrosion<br />

Prevention<br />

Hamburg, Germany<br />

24.01. – 25.01.2007<br />

The Royal Inst. <strong>of</strong> Naval<br />

Architects, „Developments<br />

in Classifi cation and<br />

International Regulations“<br />

London, UK<br />

MARCH<br />

07.03. – 09.03.2007<br />

Inmex China<br />

Guangzhou, China<br />

12.03. – 15.03.2007<br />

Seatrade Cruise Shipping<br />

Miami, USA<br />

13.03. – 15.03.2007<br />

Terminal Operations<br />

Conference Asia<br />

Hongkong, China<br />

21.03. – 22.03.2007<br />

Defence Technology Asia<br />

Singapore<br />

27.03. – 28.03.2007<br />

Intertanko<br />

Houston, USA<br />

28.03. – 29.03.2007<br />

IMarEST Propulsion<br />

BENCHMARK.<br />

German conventional submarines are<br />

among the world‘s best.<br />

SOUTH AFRICAN NAVY<br />

First-ever Classed Submarines<br />

The modern submarine fleet <strong>of</strong> the<br />

South African navy will be classified<br />

by Germanischer Lloyd. The<br />

order includes the examination <strong>of</strong><br />

engineering drawings, as well as<br />

annual safety audits. This makes<br />

Germanischer Lloyd the world’s<br />

first-ever classification society to be<br />

entrusted with the technical inspection<br />

<strong>of</strong> military submarines.<br />

The order comprises three conventional<br />

class 209, 1400 MOD-type<br />

submarines. Germanischer Lloyd will<br />

inspect the hull engineering drawings,<br />

as well as the engine and electrical<br />

systems based on <strong>GL</strong> engineering<br />

regulations for military vessels. The<br />

rules governing classifi cation <strong>of</strong> na-<br />

Maritime services trade fairs<br />

Photo: Hapag-Lloyd<br />

Conference<br />

London, UK<br />

29.03. – 30.03.2007<br />

SAFEDOR MÜNCHEN<br />

Munich, Germany<br />

APRIL<br />

02.04. – 04.04.2007<br />

Sea Asia<br />

Singapore<br />

11.04. – 12.04.2007<br />

Motorship Propulsion<br />

Conference<br />

Hamburg, Germany<br />

17.04. – 20.04.2007<br />

LAAD<br />

Rio de Janeiro, Brasil<br />

25.04. – 28.04.2007<br />

Europort Eurasia<br />

Istanbul, Turkey<br />

NEWS | MARITIME SERVICES<br />

val ships were amended by new specifi<br />

cations for military submarines in<br />

February 2005.<br />

The class. The South African submarines<br />

will receive the 100 N 6 Submarine<br />

class label. Their propulsion<br />

systems will be classed MC U.<br />

The fi rst technical inspections are<br />

stated for the spring <strong>of</strong> 2007. They<br />

will be followed by a six-year classifi<br />

cation term. Inspections by technical<br />

experts are an effective means<br />

to detect and remedy safety-relevant<br />

defects.<br />

For further information: Lorenz Petersen, Head <strong>of</strong><br />

Department, Navy Projects, Phone: +49 40 36149-254,<br />

E-Mail: lorenz.petersen@gl-group.com<br />

MAY<br />

07.05. – 08.05.2007<br />

SAFEDOR BRÜSSEL<br />

Brussels, Belgium<br />

21.05. – 24.05.2007<br />

Cimac Congress<br />

Vienna, Austria<br />

JUNE<br />

05.06.2007 – 07.06.2007<br />

Underwater Defense<br />

Technology<br />

Naples, Italy<br />

12.06. – 15.06.2007<br />

NorShipping<br />

Oslo, Norway<br />

nonstop 4/2006<br />

9

MARITIME SERVICES | NEWS<br />

ELECTRIC MOTORS<br />

Reliability for The Long Run<br />

If you ask how many electric motors<br />

are installed on a VLCC, the answer<br />

may be hesitant. “It depends,” the<br />

experts on the SMM replied. Anyway,<br />

there must be lots <strong>of</strong> them, and they<br />

must run reliably! “Our electric motors<br />

usually last for 30,000 hours <strong>of</strong><br />

<strong>GL</strong> SHIPMANAGER<br />

Successful Launch<br />

AGREEMENT. <strong>GL</strong> Executive Rainer Schöndube<br />

and NSC managing directors Roberto<br />

Echevarria and Dirk Rössler (from left).<br />

The new <strong>GL</strong> ShipManager s<strong>of</strong>tware<br />

has already won the industry over,<br />

including NSC Schifffahrtsgesellschaft<br />

mbH & Cie. KG, a shipping<br />

management company. Its core<br />

competencies include operating and<br />

chartering container vessels and conbulkers.<br />

<strong>GL</strong> ShipManager helps the company<br />

operate even more efficiently. At<br />

the SMM, top executives Echevarria<br />

and Rössler signed a s<strong>of</strong>tware license<br />

agreement for 60 ships.<br />

10 nonstop 4/2006<br />

Photo: Bogumil<br />

operation. They are designed to withstand<br />

this period <strong>of</strong> time without any<br />

problems,“ explained Ton Snijders <strong>of</strong><br />

Rotor B.V. “Maintenance on the smaller<br />

units is close to zero.”<br />

Supplier in high demand. During the<br />

SMM, Germanischer Lloyd handed<br />

JANUARY 24./25., 2007<br />

DIN EN ISO 8044, the relevant<br />

European standard, identifies<br />

37 different kinds <strong>of</strong> corrosion.<br />

Corrosive decay harbours many<br />

risks: it weakens the material;<br />

calculated bending and failure<br />

moments no longer apply.<br />

Recent research findings are<br />

the topic <strong>of</strong> the Sixth Conference<br />

on Corrosion Prevention in Hamburg,<br />

hosted by four organisations:<br />

Gesellschaft für Korrosions-<br />

SEAL OF APPROVAL.<br />

Herbert Weekhout and<br />

Arent W. J. ter Weeme <strong>of</strong> Rotor<br />

B.V. with Heinz-Dieter<br />

Hespe and Eric Endert <strong>of</strong><br />

Germanischer Lloyd<br />

(from left).<br />

over two design model test certificates<br />

for induction motors to the Eibergen,<br />

The Netherlands electric motors<br />

manufacturer. The certification is a<br />

milestone for this company that exports<br />

one-third <strong>of</strong> its annual production<br />

to Asian shipyard suppliers. Servicing<br />

the electric motors made by the<br />

Dutch manufacturer is easy, thanks to<br />

their reliability. Jointly with the classification<br />

society, pumps for essential<br />

on-board systems – such as a motor oil<br />

pump for the main machine – can be<br />

tested within a few hours on the company’s<br />

own test bench.<br />

Established in 1958, Rotor B.V. currently<br />

has 90 employees. 60 <strong>of</strong> them<br />

work in production, the others in research<br />

and development, sales and <strong>of</strong>fice<br />

functions.<br />

Conference on Corrosion Prevention<br />

schutz, Hafenbautechnische Gesellschaft,<br />

Schiffbautechnische<br />

Gesellschaft, and Germanischer<br />

Lloyd. Ten lectures will feature<br />

well-known experts from science<br />

and the industry.<br />

Registration: before January<br />

9 th , 2007, Contact: Bianca Gosch,<br />

Phone: +49 40 36149 -7703,<br />

Fax: +49 40 36149 -7154, E-Mail:<br />

bianca.gosch@gl-group.com<br />

Attendance fee: EUR 420.00<br />

Romanian Success Story<br />

The Romanian delegation pinning down classifi cation <strong>of</strong> 17 chemicals tankers <strong>of</strong><br />

37,000 tdw each (left to right): Helmut Zieger and Hans-Joachim Försterling (<strong>GL</strong>),<br />

Gheorghe Bosinceanu (President, Histria <strong>Group</strong>), Dr Hermann J. Klein (<strong>GL</strong> Executive),<br />

Radu Rusen, (Managing Director, Constanza Shipyard), and Daniel Albu,<br />

(Managing Director, Histria Shipmanagement).

Germanischer Lloyd’s<br />

Carefree S<strong>of</strong>tware Package<br />

<strong>GL</strong> ShipManager<br />

Save Costs, Reduce Your Workload, Exchange Data with Ease<br />

Administrative processes for ship<br />

operators are tedious and<br />

complex. Germanischer Lloyd’s<br />

<strong>GL</strong> ShipManager s<strong>of</strong>tware can help you<br />

streamline and automate your processes.<br />

Shipbuilders and shipowners<br />

can deploy this tool developed by the<br />

<strong>GL</strong> subsidiary Ms Logistik to save costs,<br />

reduce overheads and exchange data<br />

with ease. With user-friendly, intuitive<br />

modules and open interfaces, the Crew<br />

Management, Technical Management<br />

and Ship Management applications<br />

<strong>of</strong> <strong>GL</strong> ShipManager deliver an ideal<br />

Order your free informational CD now!<br />

Ms Logistik Systeme GmbH, Am Seehafen 7, 18147 Rostock, Germany,<br />

Phone: +49 381 673 11 35, E-Mail: sales@msls.de<br />

Free<br />

information<br />

CD !<br />

solution for managing your fl eet. This<br />

informational CD contains an overview<br />

<strong>of</strong> the most important applications<br />

and modules. It also introduces<br />

the Planned Maintenance module that<br />

supports crews in managing and monitoring<br />

system components.

COVER STORY | FUEL TANK PROTECTION<br />

<strong>Safety</strong> Ahead!<br />

<strong>Protection</strong> <strong>of</strong> fuel oil tanks: New MARPOL regulation specifi es design requirements<br />

for newbuildings. Germanischer Lloyd helps to minimize economic disadvantages<br />

while supporting high enviromental standards<br />

Today’s shipping technology not only addresses the<br />

need to protect human life and health at sea but also<br />

embraces the protection <strong>of</strong> the marine environment.<br />

Having passed resolutions on the issue <strong>of</strong> isolating cargo<br />

oil tanks to prevent sea pollution, IMO<br />

has taken on the next challenge:<br />

The ‘Marine Environment <strong>Protection</strong><br />

Committee’ (MEPC), IMO’s senior technical<br />

committee on marine pollution-related<br />

matters, responded to the need for better<br />

protection <strong>of</strong> fuel oil tanks against collision<br />

and grounding damage by preparing<br />

a new draft regulation.<br />

The result was presented to the MAR-<br />

POL convention committee, and accepted<br />

at the 48th meeting <strong>of</strong> the IMO sub-committee<br />

‘Ship Design and Equipment’ in<br />

12 nonstop 4/2006<br />

AGENDA<br />

Application <strong>of</strong> MARPOL<br />

Annex I Reg. 12 A:<br />

■ Building contract on or<br />

after 1 August 2007<br />

■ Keel laying on or<br />

after 1 February 2008<br />

■ Delivery on or after<br />

1 August 2010<br />

February 2005. The draft was subsequently approved at<br />

MEPC 53 in July 2005 and adopted in March 2006 at MEPC<br />

54. Now a revision <strong>of</strong> MARPOL Annex I Reg. 12 A, the new<br />

regulation, represents a revised design philosophy for fuel<br />

oil tank arrangements that intends to reduce<br />

the probability <strong>of</strong> oil spills due to collision<br />

or grounding damage.<br />

To minimize the economic impact on<br />

ship-owners, the regulation defines two<br />

alternative design approaches: a rather<br />

pragmatic set <strong>of</strong> descriptive rules, and a<br />

more sophisticated probabilistic approach.<br />

Both methods provide equivalent degrees<br />

<strong>of</strong> protection.<br />

While the descriptive method specifies<br />

the width <strong>of</strong> the protective double hull in<br />

a way similar to the MARPOL 1/19 require-

ments for cargo oil tanks, the probabilistic approach includes<br />

a far greater number <strong>of</strong> parameters. Based on hypothetical<br />

oil outflow probabilities, it includes oil spill calculations<br />

for side and bottom damages. This method is similar<br />

to MARPOL 1/23 for tank size limitations on tankers.<br />

Designing for Compliance<br />

Based on statistical evaluations, this method <strong>of</strong>fers the<br />

possibility for more flexible double hull shell/fuel tank arrangements<br />

and thus should try help minimize economic<br />

disadvantages <strong>of</strong> the increased space required in particular<br />

on container ships. This option <strong>of</strong> the regulation facilitates<br />

safety requirements without limiting innovative design developments<br />

<strong>of</strong> modern ships more than necessary.<br />

Compliance with the oil outflow probabilistic concept<br />

requires new ship designs to be developed. The oil outflow<br />

parameter is extremely sensitive to geometrical changes.<br />

FUEL TANK PROTECTION | COVER STORY<br />

COLLISION. In an emergency unprotected fuel oil tanks<br />

present a general risk for the enviroment.<br />

nonstop 4/2006<br />

13<br />

Photo: Sabine Vielmo

COVER STORY | FUEL TANK PROTECTION<br />

Fig. 1 Fig. 2<br />

Generally, the tanks should be located as far inboard<br />

as possible in order to avoid large outflow in the case <strong>of</strong><br />

lateral damage. <strong>Fuel</strong> tanks located directly on the double<br />

bottom should be oriented to minimize the minimum oil<br />

outflow factor, i.e. inboard <strong>of</strong> B/5. Regarding the vertical location,<br />

the bottom damage contribution can be eliminated<br />

by placing the tanks above the waterline, i.e. at 30% <strong>of</strong> the<br />

overall depth <strong>of</strong> the vessel.<br />

The ideal fuel tank arrangements depend on the type <strong>of</strong><br />

the vessel. For bulk carriers, one possible solution consists<br />

in locating the fuel tanks in the topside tanks, protected by<br />

a void space. The topside tanks are adjacent compartments<br />

extending along most <strong>of</strong> the vessel’s length, allowing easy<br />

installation <strong>of</strong> continuous piping and heating systems.<br />

A Partial Triple Bottom<br />

On tankers, some <strong>of</strong> the fuel could be carried within the<br />

engine room in tanks away from the outer shell. In some<br />

instances, the c<strong>of</strong>ferdam in front <strong>of</strong> the engine room could<br />

also be utilized for storing fuel.<br />

For container vessels, one possible solution is to construct<br />

a ‘triple bottom’, placing the fuel tank above the water<br />

ballast tank inside the double bottom. It is also possible<br />

PROTECTION OF FUEL TANKS: THE NEW IMO REGULATION FEATURES TWO APPROACHES<br />

Descriptive Requirement<br />

According to the descriptive requirement <strong>of</strong> the regulation,<br />

fuel oil tanks must be located above B/20, or at least<br />

0.76 m from the bottom, whichever is greater, not to exceed<br />

2.0 m. This is in line with new the SOLAS (SOLAS 2009 MSC<br />

80/24/Add. 1, June 2005) requirements so as to avoid subjecting<br />

vessels to different minimum double bottom height<br />

requirements resulting from different IMO conventions.<br />

Prevent Pollution. The calculation <strong>of</strong> the required wing<br />

tank widths or minimum distances from the outer shell accounts<br />

for the total fuel oil capacity. Widths range from 1 m<br />

(0.76 for tanks smaller than 500 m³ on vessels with a capacity<br />

below 5000 m³) to 2.0 m. Furthermore, the regulation<br />

includes provisions to prevent pollution from oil pipes.<br />

Application <strong>of</strong> MARPOL Annex I Reg. 12 A:<br />

<strong>Fuel</strong> oil capacity:<br />

Total aggregate fuel capacity C>_ 600 m 3<br />

Exception: individual tank capacity < 30 m 3<br />

Small tanks aggregate capacity < 600 m 3<br />

Maximum individual tank capacity 2500 m 3<br />

<strong>Fuel</strong> oil type:<br />

Heavy fuel oil, marine diesel oil, gas oil<br />

14 nonstop 4/2006<br />

For bulk carriers, one possible solution is locating<br />

the fuel tanks in the top side tanks protected by a<br />

void space (Fig. 1). For container vessels, a possible<br />

solution is to construct a ´Triple bottom`, to place the<br />

fuel tank above the water ballast tank in the double<br />

bottom (Fig. 2). Figures 3 to 5 show more possible<br />

cross-sections <strong>of</strong> a container vessel.<br />

HFO – Heavy <strong>Fuel</strong> Oil WB – Water Balast<br />

MDO – Marine Diesel Oil<br />

SHIPBUILDING. The Design must consider the new<br />

IMO regulations for fuel tank protection.<br />

to construct a partial “triple bottom” that does not extend<br />

across the entire hold area. The tanks in the turn <strong>of</strong> the bilge<br />

usually have recesses to provide a foundation on which to<br />

place the containers. They can be designed to assure the<br />

continuity <strong>of</strong> the double hull between wing and bottom<br />

Probabilistic Requirement<br />

The probabilistic approach within the regulation can<br />

be used as an alternative to the descriptive parts <strong>of</strong> the<br />

regulation regarding double bottom heights and wing tank<br />

widths. The alternative requirement is based on a probabilistic<br />

concept <strong>of</strong> non-dimensional oil outfl ow, comprising<br />

outfl ow calculations for side and bottom damages. This<br />

method was validated by extensive analyses <strong>of</strong> vessels<br />

complying with the requirements <strong>of</strong> the deterministic<br />

approach <strong>of</strong> the regulation. The mean oil outfl ow is determined<br />

irrespective <strong>of</strong> whether the damage is a side or a<br />

bottom damage and is combined into a non-dimensional<br />

computational parameter OM.<br />

More variety. When regarding grounding damages, the<br />

initial grounding, the deceleration and subsequent effects<br />

from currents, tide and waves are all taken into consideration<br />

when the oil outfl ow. A number <strong>of</strong> scientifi c research<br />

studies were undertaken to evaluate the particular effects.<br />

In summary, this approach accounts for a larger<br />

number <strong>of</strong> aspects in a more refi ned way, allowing fuel<br />

tanks to be arranged more fl exibily to accommodate special<br />

needs.However, more optimization work is obviously<br />

required.

Fig. 3 Fig. 4 Fig. 5<br />

tanks, placing the fuel tanks adjacent to these outer tanks.<br />

The fuel tanks will then provide the recesses necessary for<br />

container stowage. The triple bottom solution also provides<br />

space for piping and heating systems. Another possible design<br />

includes a double bulkhead between the cargo holds.<br />

The in-between space can be used not only for common<br />

purposes, such as an access tunnel to the holds, but also<br />

for vertical fuel tanks limited below by a non-oil compartment,<br />

and above by the partial draught. The new regulation<br />

is especially important for container ships, which have the<br />

highest fuel oil bunker capacity <strong>of</strong> all vessels.<br />

Developments for Container Ships<br />

To evaluate the effects <strong>of</strong> this new regulation on container<br />

ships, the ship type most severely affected by it, <strong>GL</strong> undertook<br />

a number <strong>of</strong> studies that went beyond the scope <strong>of</strong><br />

double hull/probabilistic oil outflow determination to include<br />

strength and stability analyses on vessels with rearranged<br />

fuel oil bunkers. In examining the resulting designs,<br />

special attention was given to quantifying and minimizing<br />

the loss <strong>of</strong> cargo space.<br />

Three typical designs were analyzed: a small container<br />

vessel <strong>of</strong> 1000 TEU (study provided by SDC, Ship Design<br />

& Consult), a Panamax container vessel <strong>of</strong> 4130 TEU and a<br />

post-Panamax with 8100 TEU.<br />

All designs were modified and evaluated in terms <strong>of</strong><br />

strength and stability in compliance with the relevant <strong>GL</strong><br />

regulations and rules.<br />

The results show that the new regulation <strong>of</strong>fers sufficient<br />

design flexibility to minimize the economic disadvantages.<br />

For further information, please contact <strong>GL</strong>. ■ HB<br />

For further information: Hendrik Bruhns, Deputy Head <strong>of</strong> Competence Centre,<br />

Ship <strong>Safety</strong>, Phone: +49 40 36149-635, E-Mail: hendrik.bruhns@gl-group.com<br />

PROBABILISTIC REQUIREMENT. The factor used to account for the<br />

minimum oil outfl ow in the event <strong>of</strong> bottom damage incorporates<br />

the results <strong>of</strong> various relevant studies and model tests.<br />

FUEL TANK PROTECTION | COVER STORY<br />

DESIGN SOLUTIONS BY GERMANISCHER LLOYD<br />

Increasing resistance <strong>of</strong> fuel oil tanks against collosion<br />

and grounding damage – the IMO draft regulation defi nes<br />

two alternative approaches that provide comparable levels<br />

<strong>of</strong> protection: the deterministic requirement and the<br />

probabilistic requirement.<br />

<strong>GL</strong> studies show that a fl exible arrangement <strong>of</strong> double<br />

skin sections should minimize the economic consequences<br />

<strong>of</strong> the increased space requirement which affects container<br />

ships in particular. In the example, the advantage is 70 TEU<br />

when compared to the deterministic approach.<br />

DETERMINISTIC DESIGN CONTAINER VESSEL<br />

POST-PANMAX tank vol C 98% m 3 container loss 70 TEU<br />

in cargo hold<br />

PROBABILISTIC DESIGN CONTAINER VESSEL<br />

POST-PANMAX tank vol C 98% m 3 container loss 0 TEU<br />

HFO – Heavy fuel oil<br />

WB – Water balast<br />

MDO – Marine diesel oil<br />

nonstop 4/2006<br />

15

MARITIME SERVICES | EMSA<br />

“Safer Than in the Past”<br />

EMSA aims at safer and cleaner shipping in the European Union.<br />

An interview with the Executive Director, Dutchman Willem de Ruiter<br />

T<br />

he European Maritime <strong>Safety</strong> Agency EMSA has moved<br />

its headquarters from Brussels to Lisbon. The inauguration<br />

<strong>of</strong> its interim new headquarters near the EXPO<br />

site on 14 September 2006 was attended by high ranking<br />

<strong>of</strong>ficials and prominent representatives <strong>of</strong> the European<br />

maritime community, among them the Portuguese Prime<br />

Minister, the President <strong>of</strong> the EU Commission and the Secretary<br />

General <strong>of</strong> IMO. The Agency took up its work in 2003<br />

and plays a central role in the EU maritime safety network.<br />

For “nonstop”, Christoph Hinz had the opportunity to talk<br />

to Willem de Ruiter, Executive Director <strong>of</strong> EMSA.<br />

nonstop: Your <strong>of</strong>fice commands a spectacular view across<br />

the river Tejo and the 12 km long Vasco-da-Gama bridge.<br />

How does it feel to work in such surroundings?<br />

Willem de Ruiter: Lisbon is a very appropriate location<br />

for EMSA. Portugal as a country with a great maritime<br />

tradition borders the Atlantic and the approaches <strong>of</strong> the<br />

Mediterranean Sea and is exposed to many <strong>of</strong> the problems<br />

which EMSA tries to tackle. Unfortunately, my work<br />

schedule doesn’t leave me much time to look out <strong>of</strong> the<br />

window!<br />

16 nonstop 4/2006<br />

SHANGHAI.<br />

A single-hull tanker under construction.<br />

nonstop: What is EMSA’s role among the national administrations,<br />

the EU Commission and the international organizations<br />

responsible for maritime safety?<br />

de Ruiter: EMSA was founded in the wake <strong>of</strong> serious ferry<br />

accidents such as Herald <strong>of</strong> Free Enterprise, the Estonia,<br />

Express Samina in the nineties and after the oil tanker disasters<br />

Erika (1991) and Prestige (2002). European leaders<br />

concluded that a determined effort had to be made to improve<br />

the safety <strong>of</strong> shipping in European waters. National<br />

measures alone were not enough. A European dimension<br />

had to be added to effectively protect the thousands <strong>of</strong><br />

kilometres <strong>of</strong> coastline and over 600 major ports <strong>of</strong> the European<br />

countries.<br />

nonstop: The EU has adopted a large number <strong>of</strong> regulations<br />

on maritime safety which are being implemented by the<br />

member states. Which added value can EMSA provide?<br />

de Ruiter: The prime responsibility for maritime safety and<br />

pollution prevention remains with the member states. You<br />

may call EMSA the “technical arm” <strong>of</strong> the EU Commission.<br />

It assists the Commission in monitoring the implementation<br />

<strong>of</strong> the EU maritime legislation by the member states.<br />

REMOVAL.<br />

EMSA at its<br />

interim new<br />

headquarters<br />

in Lisbon.<br />

Photos: EMSA

It gives technical advice for updating the legislation. In<br />

addition, it facilitates technical operation between member<br />

states and the Commission. Thirdly, after the sinking<br />

<strong>of</strong> the tanker Prestige, it was decided to give EMSA an operational<br />

task in the field <strong>of</strong> pollution response, which is<br />

complementary to the response mechanisms <strong>of</strong> the member<br />

states.<br />

nonstop: How does EMSA monitor the implementation <strong>of</strong><br />

EU maritime legislation and what are the priorities?<br />

de Ruiter: At present the Agency is involved in different<br />

types <strong>of</strong> assessments:<br />

Firstly, we assess maritime administrations regarding their<br />

obligations as flag states and as port states. One priority is<br />

Port State Control. Member states are required to inspect<br />

at least 25% <strong>of</strong> the ships which enter their ports. EMSA<br />

controllers ensure that Port State Control <strong>of</strong>ficers throughout<br />

the EU apply the same methods. EMSA also publishes<br />

the list <strong>of</strong> vessels that are banned from European ports because<br />

<strong>of</strong> grave deficiencies.<br />

Secondly, we assess classification societies.<br />

Thirdly, we assess educational systems in third countries,<br />

verifying compliance with the STCW convention rules for<br />

training <strong>of</strong> seafarers. Our motive: 75% <strong>of</strong> seafarers on EU<br />

registered ships originate from non-EU countries and are<br />

trained in non-EU schools. Nationals <strong>of</strong> 40 non-EU coun -<br />

t ries (46.5% from the Philippines alone) are employed on<br />

EU flagged ships. EMSA experts carry out an assessment <strong>of</strong><br />

the education system in these countries once every 5 years.<br />

Here you have a clear case <strong>of</strong> added value: EMSA checks<br />

the quality <strong>of</strong> nautical colleges in third countries for the<br />

EMSA | MARITIME SERVICES<br />

DIRECTOR. Before joining<br />

EMSA, Willem de<br />

Ruiter was responsible<br />

for maritime safety in<br />

the EU Commission.<br />

“It is estimated that around 80% <strong>of</strong> the accidents at sea occur as<br />

a result <strong>of</strong> human error.” Willem de Ruiter<br />

benefit <strong>of</strong> all member states instead <strong>of</strong> each <strong>of</strong> them doing<br />

it individually.<br />

Fourthly, we assess security organizations, companies<br />

and ships regarding compliance with the ISPS Code.<br />

nonstop: How does all this affect the classification societies?<br />

de Ruiter: The classification societies are one <strong>of</strong> the most<br />

important parts <strong>of</strong> the maritime safety chain. Most member<br />

states have delegated their duties <strong>of</strong> controlling the<br />

construction and maintenance <strong>of</strong> ships to classification<br />

societies recognized under EU law. Of more than 50 such<br />

organizations worldwide only 12 are recognized by the EU.<br />

These, however, survey and certify more than 90% <strong>of</strong> the<br />

world’s tonnage.<br />

In order to ensure compliance with the quality standards<br />

laid down in Directive 94/57/DC each <strong>of</strong> the EU recognized<br />

classification societies is assessed once every two<br />

years. The agency’s assessors visit the head <strong>of</strong>fice, regional<br />

<strong>of</strong>fices, individual ships and ship-building sites.<br />

nonstop: EMSA has concluded standby availability contracts<br />

for oil recovery vessels. Does the agency take on operative<br />

tasks in this field and will it broaden its assistance relating<br />

to other pollutants?<br />

de Ruiter: The Prestige disaster has clearly shown that there<br />

is not enough pollution response capacity to deal with major<br />

oil spills in European waters. For this reason EMSA was<br />

requested to set up a network <strong>of</strong> vessels, equipment and<br />

other resources to help member states to deal with oil pollution<br />

from ships. The Baltic Sea, the Atlantic coast and the<br />

western approaches to the Channel and the Mediterra-<br />

nonstop 4/2006<br />

17

MARITIME SERVICES | EMSA<br />

nean were identified as sensitive areas for this purpose.<br />

Standby contracts have been concluded with private companies<br />

which will make their vessels – normally employed<br />

in commercial trade, but equipped with oil recovery and<br />

storage systems – available at short notice. This spill response<br />

capacity is available to coastal states on request<br />

and does not replace the prime responsibility<br />

<strong>of</strong> member states for fighting oil pol-<br />

lution. The Agency is at present studying<br />

whether the operational assistance can<br />

be extended to other pollutants like light<br />

oil and other chemicals. This is a complex<br />

exercise in view <strong>of</strong> the vast number <strong>of</strong><br />

chemicals transported and their different<br />

properties.<br />

nonstop: What is the current state <strong>of</strong> maritime<br />

safety and pollution prevention in<br />

European waters? Have the Maritime <strong>Safety</strong><br />

Packages Erika I and II and the controls<br />

by EMSA led to tangible improvements?<br />

de Ruiter: It is too early to judge the overall<br />

impact <strong>of</strong> EMSA’s activities. But there is a<br />

positive trend. EU waters are now generally<br />

safer than in the past. Ships inspected<br />

by EU-recognized organizations are doing<br />

well in Port State Control statistics.<br />

They are rarely detained for class related Willem de Ruiter<br />

deficiencies.<br />

The safety situation in the European<br />

Union will be further improved when the<br />

IT-system SafeSeaNet becomes fully operational. This will<br />

harmonize the maritime data exchange between member<br />

states and enable them to monitor the more than 20,000<br />

ships operating in European waters at any given time.<br />

nonstop: Where does EMSA see the major risks for maritime<br />

safety and clean seas? Is the technical quality <strong>of</strong> the ships<br />

or the human factor the crucial point?<br />

de Ruiter: It is estimated that around 80% <strong>of</strong> the accidents<br />

at sea occur as a result <strong>of</strong> human error. But it is difficult<br />

to draw general conclusions from accidents because accident<br />

investigation in European countries follows different<br />

methods and results are not comparable.<br />

This is why EMSA argues in favour <strong>of</strong> an EU marine ac-<br />

EMSA: THE SAFETY EXPERTS<br />

18 nonstop 4/2006<br />

HEADQUARTERS.<br />

From Lisbon<br />

EMSA fi ghts for<br />

environmental<br />

protection and<br />

safety.<br />

Photo: EMSA<br />

“A cause <strong>of</strong><br />

concern is the<br />

increasing oil<br />

tanker traffi c in<br />

enclosed waters<br />

such as the<br />

Baltic Sea.”<br />

Headquartered in Lisbon,<br />

the European Maritime<br />

<strong>Safety</strong> Agency (EMSA) is<br />

the technical and operative<br />

body <strong>of</strong> the European Union<br />

dedicated to promoting<br />

shipping safety and pollution<br />

prevention in European<br />

waters.<br />

The beginnings. Two oil<br />

tanker disasters, “Erika” <strong>of</strong>f<br />

the French coast in 1999,<br />

and “Prestige” near Spain in<br />

2002, severely affected the<br />

inhabitants <strong>of</strong> the coastal areas<br />

and the environment. In<br />

cident database which would contain data supplied by<br />

the member states in a common format. This would be an<br />

important source <strong>of</strong> accident information in Europe and<br />

would assist in future decisions on maritime safety.<br />

Apart from this, a cause <strong>of</strong> concern is the increasing<br />

oil tanker traffic in enclosed waters like the Baltic and the<br />

Black Sea. The worldwide shipbuilding<br />

boom also begs the question whether high<br />

output <strong>of</strong> newbuildings and quality will go<br />

hand in hand.<br />

nonstop: How does EMSA organize its cooperation<br />

with IMO in London in order to<br />

maintain IMO’s position as a global regulator<br />

<strong>of</strong> shipping?<br />

de Ruiter: Merchant shipping is international<br />

and needs global standards. EMSA represents<br />

the EU Commission in IMO’s technical<br />

work. It helps the Commission and the<br />

member states to prepare European positions<br />

and initiatives for IMO’s regulatory<br />

framework.<br />

nonstop: What are the priorities for EMSA’s<br />

future work?<br />

de Ruiter: The future agenda will be influenced<br />

by the Third Maritime <strong>Safety</strong> Package<br />

which is being discussed by the European<br />

Parliament and by the Council <strong>of</strong><br />

Ministers. It deals with many issues with<br />

which EMSA concerns itself: flagstate responsibility,<br />

Port State Control, classification<br />

societies, traffic monitoring, accident investigation,<br />

liability. It remains to be seen which additional tasks for<br />

EMSA will flow from decisions about this package.<br />

Other priorities include the conclusions <strong>of</strong> additional<br />

contracts for standby oil recovery vessels and setting up a<br />

satellite surveillance system to monitor large sea areas to<br />

detect illegal discharges and accidental oil spills.<br />

nonstop: And when will EMSA move into its permanent<br />

purpose-built headquarters in Lisbon?<br />

de Ruiter: We hope to be able to open our new <strong>of</strong>fice at the<br />

waterfront in the historical centre <strong>of</strong> Lisbon towards the<br />

end <strong>of</strong> 2007.<br />

nonstop: Mr de Ruiter, thank you very much! ■ CH<br />

response, several EU institutions<br />

launched initiatives to<br />

enhance safety. The result:<br />

the EU established EMSA<br />

which began its work in 2003.<br />

The issue. The European<br />

Union’s 25 member countries<br />

operate more than 600<br />

important seaports. Roughly<br />

90% <strong>of</strong> the EU’s imports and<br />

exports, and about one-third<br />

<strong>of</strong> its internal trade volume<br />

pass through these ports. An<br />

increasing number <strong>of</strong> the<br />

ships sailing on European<br />

waters are oil tankers.<br />

The objectives. EMSA<br />

advises the EU Commission<br />

and the member countries<br />

on all issues surrounding<br />

maritime safety. It also<br />

monitors the implementation<br />

<strong>of</strong>, and adherence to,<br />

the respective EU laws and<br />

regulations by the member<br />

countries and organizations.<br />

Furthermore EMSA audits<br />

port authorities, classifi cation<br />

societies and training<br />

facilities, and assists the<br />

EU member countries in<br />

coping with oil spills.

Cool Transport<br />

The shipping <strong>of</strong> perishable goods in refrigerated containers is booming. Sophisticated<br />

refrigeration and ventilation systems inside the vessels help to reduce operating costs<br />

ASalmon from Alaska, lamb from New Zealand, bananas<br />

from Honduras: the food on dining tables in Germany<br />

and elsewhere has <strong>of</strong>ten travelled thousands <strong>of</strong><br />

nautical miles. According to statistics from Drewry Shipping<br />

Consultants, 57.1 million tons <strong>of</strong> refrigerated cargo<br />

were shipped across the seven seas in 2005 – more than<br />

twice much as 25 years ago.<br />

The bulk <strong>of</strong> perishable goods is now transported in refrigerated<br />

containers – which poses a big challenge for designers<br />

and shipbuilders alike: if the refrigeration units<br />

in the containers are to work efficiently, cool air must be<br />

pumped into, in particular, the ship’s hold and the warm<br />

air pumped out.<br />

Germanischer Lloyd’s new simulation system enables<br />

ship designers and shipyards to construct effective ventilation<br />

systems for any ship type. <strong>GL</strong> Vent simulates different<br />

operating, load distribution and temperature situations.<br />

The s<strong>of</strong>tware provides the necessary data for the installation<br />

<strong>of</strong> effective and economical ventilation systems and<br />

analyzes the weaknesses <strong>of</strong> fitted systems.<br />

Enormous Cost-Saving Potential<br />

Demand is growing. Although around half <strong>of</strong> all bananas<br />

are still being transported on reefer vessels, hardly any<br />

new vessels have been built for years, and the trend towards<br />

refrigerated containers is stronger than ever before.<br />

The annual transport capacities in this sector are now rising<br />

by 14% on average, which is even faster than the overall<br />

market for refrigerated cargo. Ten years ago, capacity was<br />

267,000 TEU; this figure has now reached 746,000 TEU.<br />

Currently there are 2200 vessels worldwide that transport<br />

CONTAINER. The<br />

refrigerating set needs a<br />

suffi cient ventilation.<br />

Source: Drewery Shipping Consultants<br />

refrigerated containers. The largest <strong>of</strong> these, the ‘Monte<br />

Cervantes’ owned by the shipping company Hamburg-Süd,<br />

has a total loading capacity <strong>of</strong> 5100 TEU, <strong>of</strong> which 2450<br />

TEU can be used for refrigerated containers.<br />

There are still two different container types in operation:<br />

integrated containers with an inbuilt refrigeration unit, and<br />

porthole containers without any additional refrigeration.<br />

However, most shipowners have gone over to using integrated<br />

containers. In 2002, the proportion <strong>of</strong> porthole types<br />

on the world market was less than five per cent.<br />

As for container loading capacities, the trend is towards<br />

a larger volume inside the container. Traditional 40-foot<br />

standard containers with a height <strong>of</strong> 8’ 6” are increasingly<br />

being replaced by high-cube containers (height: 9’ 6”).<br />

Nonetheless, 20-foot containers are still just as important<br />

as before. Heavy reefer cargo, such as meat and fish, would<br />

soon exceed the maximum weight <strong>of</strong> 30 tons if stuffed in<br />

larger containers.<br />

As the number, size and weight <strong>of</strong> refrigerated containers<br />

grow, they are increasingly being stowed in the ship’s<br />

hold rather than on deck. To make sure there is sufficient<br />

cooling, the ambient air temperature may not exceed 45 degrees<br />

centigrade. A 40-foot container requires 4,500 cubic<br />

metres <strong>of</strong> air per hour, and a 20-foot container needs 3,100<br />

cubic metres. This is because, depending on the goods and<br />

room climate, a stand-alone 40-foot container produces<br />

between 7 and 15 kW <strong>of</strong> heat. These values increase even<br />

more depending on how many boxes are in the hold.<br />

<strong>GL</strong> calculations prove the economic importance <strong>of</strong> sophisticated<br />

and optimized ventilation systems: if there are<br />

700 TEU in the ship’s hold and the ambient air temperature<br />

drops by one degree, the energy consumption <strong>of</strong> refrigerated<br />

containers with frozen cargo is reduced by 3.8 per cent<br />

and that <strong>of</strong> containers holding frozen fruit by 2.1 per cent.<br />

According to these calculations, the ship operators save approx.<br />

EUR 50,000 per year in the operation <strong>of</strong> their ventilation<br />

systems – and salmon, lamb and the rest are sure to<br />

reach their destinations in perfect condition. ■ JH<br />

For further Information: Hanspeter Raschle, Piping Systems/Tanker,<br />

Phone: +49 40-361 495 69, E-Mail: hanspeter.raschle@gl-group.com<br />

15<br />

10<br />

5<br />

0<br />

Bananas<br />

Meat<br />

Citrus fruit<br />

<strong>GL</strong> VENT | MARITIME SERVICES<br />

Development <strong>of</strong> refrigerated cargo transport<br />

millions <strong>of</strong> tons<br />

20<br />

Saisonal fruit<br />

Fish products<br />

Diary products<br />

nonstop 4/2006<br />

1981<br />

2005<br />

19

MARITIME SERVICES | ERS<br />

SOS at 0.30 a.m.<br />

500th ship registered: The powerful Emergency Response Service<br />

ensures effi cient handling <strong>of</strong> sea damages<br />

Acontainer vessel runs aground on a mud bank. A<br />

cruise ship scrapes a reef. A bulk carrier and a container<br />

ship jam into each other. A fire breaks out in<br />

a cargo hold. The many different scenarios the Emergency<br />

Response Service (ERS) <strong>of</strong> Germanischer Lloyd has to<br />

handle are <strong>of</strong>ten hazardous for both the seamen involved<br />

and the environment. The emergency service for ships in<br />

trouble has been operating since 1993 – and with great<br />

success. The 500 th vessel joins ERS in November 2006.<br />

The ship it was issued for is “Histria<br />

Perla”, a Romanian chemical tanker with<br />

a tonnage <strong>of</strong> 40,471 dwt. Built in 2005 by<br />

Romanian shipbuilder Constantza Shipyard,<br />

the vessel was classed by Germanischer<br />

Lloyd. On 8 November, Nicolae<br />

Berechet, Technical Director <strong>of</strong> Histria<br />

Shipmanagement, received the ERS certificate<br />

by Germanischer Lloyd.<br />

Effi cient Emergency Management<br />

The advantages <strong>of</strong> an emergency response<br />

system are obvious. “What makes<br />

our services attractive for ship-owners<br />

is the fact that an efficient emergency<br />

management can save them substantial<br />

amounts <strong>of</strong> money on damages that would otherwise escalate,<br />

costing them hundreds <strong>of</strong> millions <strong>of</strong> euros,” explains<br />

Norbert Kray, head <strong>of</strong> Germanischer Lloyd’s Technical<br />

Support Department. Customers pay only a three-digit<br />

sum per ship annually for access to the emergency service<br />

<strong>of</strong> Germanischer Lloyd. The service comprises competent<br />

damage analysis and recovery recommendations for sea<br />

damages. “Our rapid response not only saves costs but also<br />

reduces environmental damages considerably,” Kray says.<br />

Henning Schier, general manager <strong>of</strong> the Emergency Re-<br />

SUCCESS STORY. „Histria Perla“<br />

is already the 500 th<br />

ERS certifi ed ship.<br />

20 nonstop 4/2006<br />

sponse Service <strong>of</strong> Germanischer Lloyd, and his team are on<br />

call around the clock. Henning Schier describes a typical<br />

emergency scenario: “ERS alarm is triggered by telephone,<br />

using a dedicated phone number. The emergency call is<br />

first received by the Maritime Rescue Coordination Centre<br />

<strong>of</strong> the German Maritime Rescue Service (GMRS) in Bremen.<br />

The GMRS immediately notifies our ERS team. Dedicated<br />

emergency telephone, fax, telex and e-mail connections<br />

ensure smooth communication between the ship and <strong>GL</strong>.”<br />

The emergency service relies on a<br />

computational model containing comprehensive<br />

technical specifications <strong>of</strong> the<br />

respective ship. Germanischer Lloyd uses<br />

HECSALV, a specialized Salvage S<strong>of</strong>tware.<br />

If the troubled ship has been classified by<br />

<strong>GL</strong>, existing model data can be used. But<br />

Kray emphasizes: “A ship doesn’t have to<br />

have been classed by us in order to be eligible<br />

for ERS certification.”<br />

In an emergency, the ERS experts use<br />

their computers to simulate the accident<br />

and obtain a detailed insight into the current<br />

state <strong>of</strong> the ship. Following a thorough<br />

analysis <strong>of</strong> the situation, they make<br />

recommendations for a possible rescue scenario.<br />

“We leverage the full range <strong>of</strong> expertise accumulated<br />