Protection of Fuel Tanks Safety ahead! - GL Group

Protection of Fuel Tanks Safety ahead! - GL Group

Protection of Fuel Tanks Safety ahead! - GL Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COVER STORY | FUEL TANK PROTECTION<br />

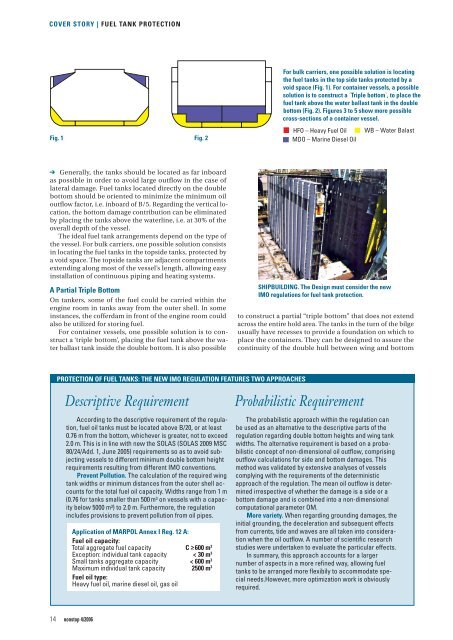

Fig. 1 Fig. 2<br />

Generally, the tanks should be located as far inboard<br />

as possible in order to avoid large outflow in the case <strong>of</strong><br />

lateral damage. <strong>Fuel</strong> tanks located directly on the double<br />

bottom should be oriented to minimize the minimum oil<br />

outflow factor, i.e. inboard <strong>of</strong> B/5. Regarding the vertical location,<br />

the bottom damage contribution can be eliminated<br />

by placing the tanks above the waterline, i.e. at 30% <strong>of</strong> the<br />

overall depth <strong>of</strong> the vessel.<br />

The ideal fuel tank arrangements depend on the type <strong>of</strong><br />

the vessel. For bulk carriers, one possible solution consists<br />

in locating the fuel tanks in the topside tanks, protected by<br />

a void space. The topside tanks are adjacent compartments<br />

extending along most <strong>of</strong> the vessel’s length, allowing easy<br />

installation <strong>of</strong> continuous piping and heating systems.<br />

A Partial Triple Bottom<br />

On tankers, some <strong>of</strong> the fuel could be carried within the<br />

engine room in tanks away from the outer shell. In some<br />

instances, the c<strong>of</strong>ferdam in front <strong>of</strong> the engine room could<br />

also be utilized for storing fuel.<br />

For container vessels, one possible solution is to construct<br />

a ‘triple bottom’, placing the fuel tank above the water<br />

ballast tank inside the double bottom. It is also possible<br />

PROTECTION OF FUEL TANKS: THE NEW IMO REGULATION FEATURES TWO APPROACHES<br />

Descriptive Requirement<br />

According to the descriptive requirement <strong>of</strong> the regulation,<br />

fuel oil tanks must be located above B/20, or at least<br />

0.76 m from the bottom, whichever is greater, not to exceed<br />

2.0 m. This is in line with new the SOLAS (SOLAS 2009 MSC<br />

80/24/Add. 1, June 2005) requirements so as to avoid subjecting<br />

vessels to different minimum double bottom height<br />

requirements resulting from different IMO conventions.<br />

Prevent Pollution. The calculation <strong>of</strong> the required wing<br />

tank widths or minimum distances from the outer shell accounts<br />

for the total fuel oil capacity. Widths range from 1 m<br />

(0.76 for tanks smaller than 500 m³ on vessels with a capacity<br />

below 5000 m³) to 2.0 m. Furthermore, the regulation<br />

includes provisions to prevent pollution from oil pipes.<br />

Application <strong>of</strong> MARPOL Annex I Reg. 12 A:<br />

<strong>Fuel</strong> oil capacity:<br />

Total aggregate fuel capacity C>_ 600 m 3<br />

Exception: individual tank capacity < 30 m 3<br />

Small tanks aggregate capacity < 600 m 3<br />

Maximum individual tank capacity 2500 m 3<br />

<strong>Fuel</strong> oil type:<br />

Heavy fuel oil, marine diesel oil, gas oil<br />

14 nonstop 4/2006<br />

For bulk carriers, one possible solution is locating<br />

the fuel tanks in the top side tanks protected by a<br />

void space (Fig. 1). For container vessels, a possible<br />

solution is to construct a ´Triple bottom`, to place the<br />

fuel tank above the water ballast tank in the double<br />

bottom (Fig. 2). Figures 3 to 5 show more possible<br />

cross-sections <strong>of</strong> a container vessel.<br />

HFO – Heavy <strong>Fuel</strong> Oil WB – Water Balast<br />

MDO – Marine Diesel Oil<br />

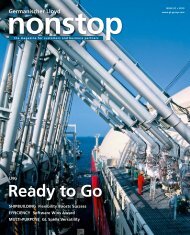

SHIPBUILDING. The Design must consider the new<br />

IMO regulations for fuel tank protection.<br />

to construct a partial “triple bottom” that does not extend<br />

across the entire hold area. The tanks in the turn <strong>of</strong> the bilge<br />

usually have recesses to provide a foundation on which to<br />

place the containers. They can be designed to assure the<br />

continuity <strong>of</strong> the double hull between wing and bottom<br />

Probabilistic Requirement<br />

The probabilistic approach within the regulation can<br />

be used as an alternative to the descriptive parts <strong>of</strong> the<br />

regulation regarding double bottom heights and wing tank<br />

widths. The alternative requirement is based on a probabilistic<br />

concept <strong>of</strong> non-dimensional oil outfl ow, comprising<br />

outfl ow calculations for side and bottom damages. This<br />

method was validated by extensive analyses <strong>of</strong> vessels<br />

complying with the requirements <strong>of</strong> the deterministic<br />

approach <strong>of</strong> the regulation. The mean oil outfl ow is determined<br />

irrespective <strong>of</strong> whether the damage is a side or a<br />

bottom damage and is combined into a non-dimensional<br />

computational parameter OM.<br />

More variety. When regarding grounding damages, the<br />

initial grounding, the deceleration and subsequent effects<br />

from currents, tide and waves are all taken into consideration<br />

when the oil outfl ow. A number <strong>of</strong> scientifi c research<br />

studies were undertaken to evaluate the particular effects.<br />

In summary, this approach accounts for a larger<br />

number <strong>of</strong> aspects in a more refi ned way, allowing fuel<br />

tanks to be arranged more fl exibily to accommodate special<br />

needs.However, more optimization work is obviously<br />

required.