Issue 06/2020

Highlights: Films / Flexibles Bioplastics from waste-streams Basics: Eutrophication

Highlights:

Films / Flexibles

Bioplastics from waste-streams

Basics: Eutrophication

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Applications<br />

By 2024, Reebok’s sustainability mission is for shoes to<br />

be “made from things that grow’ rather than petroleumbased<br />

plastics and also to be free of virgin polyester, a nonrenewable<br />

and non-biodegradable resource.” said Mike<br />

Andrews, Advanced Development Director at Reebok, at<br />

thebeet.com<br />

product is recyclable in theory it is not recycled in practice.<br />

This has various reasons often outside the control of the<br />

product producer, so On decided to take out the middleman<br />

and plans to recycle the shoe themselves. Actually, it is a vital<br />

part of the Cyclon project, because it is a shoe you don’t own,<br />

not in the classical sense - it is a shoe subscription. At the end<br />

of their lifetime - which according to On is reached after six to<br />

nine months for active runners - the shoes are to be returned<br />

and the subscriber receives a new pair. On then processes<br />

the returned shoes into new products, promising to recycle<br />

100% of the material. The project is planned to launch next<br />

year. AT/MT<br />

www.toms.com | www.braskem.com | www.arkema.com<br />

www.mizuno.com | www.pebaxpowered.com | www.reebok.com<br />

www.bloomtreadwell.com<br />

On running<br />

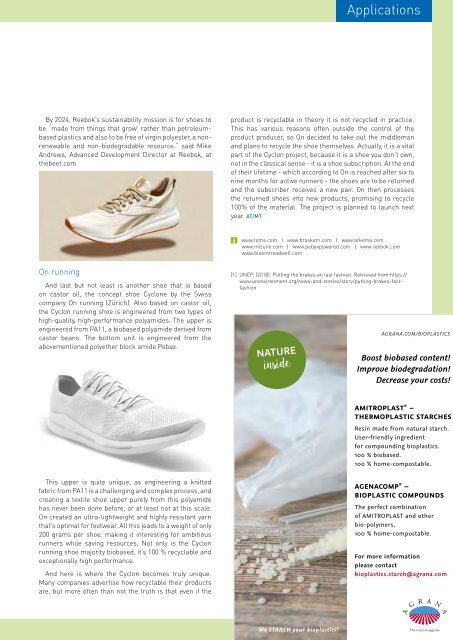

And last but not least is another shoe that is based<br />

on castor oil, the concept shoe Cyclone by the Swiss<br />

company On running (Zürich). Also based on castor oil,<br />

the Cyclon running shoe is engineered from two types of<br />

high-quality, high-performance polyamides. The upper is<br />

engineered from PA11, a biobased polyamide derived from<br />

castor beans. The bottom unit is engineered from the<br />

abovementioned polyether block amide Pebax.<br />

[1] UNEP. (2018). Putting the brakes on fast fashion. Retrieved from https://<br />

www.unenvironment.org/news-and-stories/story/putting-brakes-fastfashion<br />

NATURE<br />

inside<br />

AGRANA.COM/BIOPLASTICS<br />

Boost biobased content!<br />

Improve biodegradation!<br />

Decrease your costs!<br />

Agrana<br />

AMITROPLAST ® –<br />

THERMOPLASTIC STARCHES<br />

Resin made from natural starch.<br />

User-friendly ingredient<br />

for compounding bioplastics.<br />

100 % biobased.<br />

100 % home-compostable.<br />

This upper is quite unique, as engineering a knitted<br />

fabric from PA11 is a challenging and complex process, and<br />

creating a textile shoe upper purely from this polyamide<br />

has never been done before, or at least not at this scale.<br />

On created an ultra-lightweight and highly resistant yarn<br />

that’s optimal for footwear. All this leads to a weight of only<br />

200 grams per shoe, making it interesting for ambitious<br />

runners while saving resources. Not only is the Cyclon<br />

running shoe majority biobased, it’s 100 % recyclable and<br />

exceptionally high performance.<br />

And here is where the Cyclon becomes truly unique.<br />

Many companies advertise how recyclable their products<br />

are, but more often than not the truth is that even if the<br />

AGENACOMP ® –<br />

BIOPLASTIC COMPOUNDS<br />

The perfect combination<br />

of AMITROPLAST and other<br />

bio-polymers.<br />

100 % home-compostable.<br />

For more information<br />

please contact<br />

bioplastics.starch@agrana.com<br />

We STARCH your bioplastics!<br />

bioplastics MAGAZINE [<strong>06</strong>/20]<br />

The<br />

Vol.<br />

natural<br />

15<br />

upgrade31