Issue 01/2021

Highlights: Automotive Foam Basics: Enzymes

Highlights:

Automotive

Foam

Basics: Enzymes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Automotive<br />

Automotive supplier<br />

launches PLA compounds<br />

The automotive industry is increasingly working<br />

on aligning vehicle production with the principles<br />

of sustainability. The development of appropriate<br />

materials plays a decisive role in this process. Röchling<br />

Automotive, an automotive supplier based in Mannheim<br />

Germany, has already started a biopolymer project in 2<strong>01</strong>0,<br />

but the market at the time had not been quite ready. Now,<br />

Röchling believes, it is. A good decade later interest in<br />

alternative materials, as well as recycled materials is rising.<br />

BioBoom is the name of Röchling’s patented polylactide<br />

(PLA)-based biopolymer that consists of at least 90 %<br />

renewable raw materials. It offers an ecological, as well as<br />

an economical alternative to most conventional materials.<br />

Three standard types within the BioBoom family are<br />

currently available, which are suitable for applications in<br />

the engine compartment and underbody as well as for the<br />

interior of a vehicle. Each of the three types can be tailored<br />

to individual customer needs and their respective specific<br />

requirements. Röchling’s BioBoom can also be used for<br />

almost their entire product portfolio (around 70 %).<br />

With significant improvements in terms of thermal<br />

stability and chemical resistance compared to standard<br />

PLA, the new biopolymer family meets the company’s high<br />

technical requirements and specifications. More concrete,<br />

some material grades can withstand continuous operating<br />

temperatures of up to 150°C (as a counter-example, PP<br />

maxes out at around 130–140°C). Most parts under the hood<br />

should not reach these temperatures for longer durations<br />

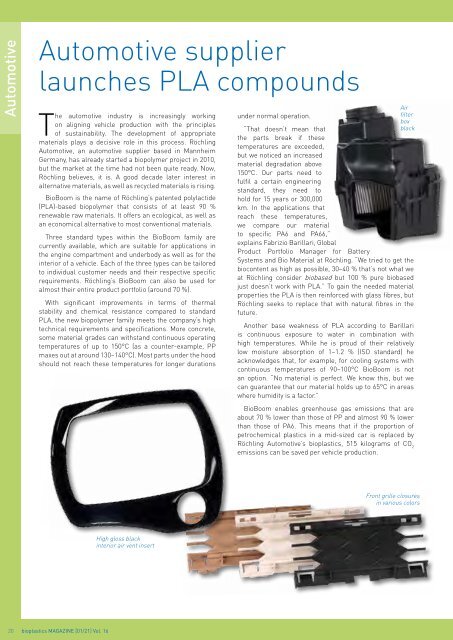

Air<br />

under normal operation.<br />

filter<br />

box<br />

“That doesn’t mean that<br />

black<br />

the parts break if these<br />

temperatures are exceeded,<br />

but we noticed an increased<br />

material degradation above<br />

150°C. Our parts need to<br />

fulfil a certain engineering<br />

standard, they need to<br />

hold for 15 years or 300,000<br />

km. In the applications that<br />

reach these temperatures,<br />

we compare our material<br />

to specific PA6 and PA66,”<br />

explains Fabrizio Barillari, Global<br />

Product Portfolio Manager for Battery<br />

Systems and Bio Material at Röchling. “We tried to get the<br />

biocontent as high as possible, 30–40 % that’s not what we<br />

at Röchling consider biobased but 100 % pure biobased<br />

just doesn’t work with PLA.” To gain the needed material<br />

properties the PLA is then reinforced with glass fibres, but<br />

Röchling seeks to replace that with natural fibres in the<br />

future.<br />

Another base weakness of PLA according to Barillari<br />

is continuous exposure to water in combination with<br />

high temperatures. While he is proud of their relatively<br />

low moisture absorption of 1–1.2 % (ISO standard) he<br />

acknowledges that, for example, for cooling systems with<br />

continuous temperatures of 90–100°C BioBoom is not<br />

an option. “No material is perfect. We know this, but we<br />

can guarantee that our material holds up to 65°C in areas<br />

where humidity is a factor.”<br />

BioBoom enables greenhouse gas emissions that are<br />

about 70 % lower than those of PP and almost 90 % lower<br />

than those of PA6. This means that if the proportion of<br />

petrochemical plastics in a mid-sized car is replaced by<br />

Röchling Automotive’s bioplastics, 515 kilograms of CO 2<br />

emissions can be saved per vehicle production.<br />

Front grille closures<br />

in various colors<br />

High gloss black<br />

interior air vent insert<br />

20 bioplastics MAGAZINE [<strong>01</strong>/21] Vol. 16