bioplasticsMAGAZINE_0703

bioplasticsMAGAZINE_0703

bioplasticsMAGAZINE_0703

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The general availability of the biopolymers can be divided<br />

into different material types. The most important<br />

are starch, polylactide (PLA) and polyester polymers,<br />

plus blends made out of these. Table 3 shows the different<br />

currently available types of biopolymer materials<br />

(including blends), and their potential by 2010.<br />

From an application viewpoint there is a significant<br />

diversity in the number of currently commercially available<br />

material types and the number of manufacturers<br />

(Table 4).<br />

Based on a detailed investigation it can be established<br />

that there are 26 commercial producers of biopolymers.<br />

In addition many more companies and<br />

research entities are currently active at the R&D level<br />

and/or operate on the Asian market only. Altogether,<br />

approximately 60 companies are currently known to be<br />

active in the field of biopolymers.<br />

The most important countries producing biodegradable,<br />

thermoplastic biopolymers on an industrial level<br />

include the USA, Western Europe, the Far East and<br />

Australia (Table 5). Various countries have their own<br />

priorities concerning the material types. This may be<br />

attributed to their particular R&D history, the local<br />

availability of raw materials or simply the company location.<br />

Looking at the future, there is reason to assume that<br />

the market for biopolymers will continue to expand<br />

rapidly and undergo further changes in the coming<br />

years. While the second generation of biopolymers was<br />

developed almost exclusively for use as biodegradable<br />

packaging, a third generation will be developed for application<br />

in other fields, e.g., the automotive industry,<br />

consumer electronics, textiles or building, etc. Beside<br />

the utilisation of renewable raw materials and their<br />

different end of life options additional new technical<br />

questions will have to be addressed, including heat deflection,<br />

fogging, colouring, impact behaviour, UV-stabilisation<br />

etc. And finally the search for new biopolymer<br />

additives and refined manufacturing technologies will<br />

continue.<br />

The project on which this paper is based (see bioplastics<br />

MAGAZINE 01/2007 p. 12) is carried out in cooperation<br />

with M-Base, Aachen, Germany and supported by<br />

the German BMELV (German Federal Ministry of Food,<br />

Agriculture and Consumer Protection), represented by<br />

FNR (Professional Agency for Renewable Resources).<br />

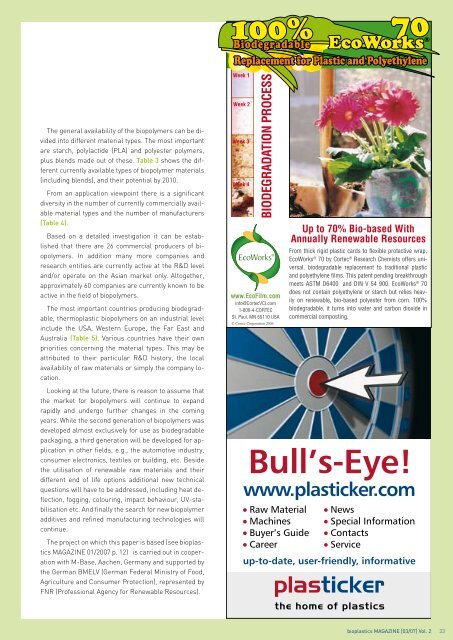

Week 1<br />

Week 2<br />

Week 3<br />

Week 4<br />

BIODEGRADATION PROCESS<br />

EcoWorks ®<br />

www.EcoFilm.com<br />

info@CortecVCI.com<br />

1-800-4-CORTEC<br />

St. Paul, MN 55110 USA<br />

© Cortec Corporation 2006<br />

70®<br />

100%<br />

Biodegradable EcoWorks<br />

Replacement for Plastic and Polyethylene<br />

Up to 70% Bio-based With<br />

Annually Renewable Resources<br />

From thick rigid plastic cards to fl exible protective wrap,<br />

EcoWorks ® 70 by Cortec ® Research Chemists offers universal,<br />

biodegradable replacement to traditional plastic<br />

and polyethylene films. This patent pending breakthrough<br />

meets ASTM D6400 and DIN V 54 900. EcoWorks ® 70<br />

does not contain polyethylene or starch but relies heavily<br />

on renewable, bio-based polyester from corn. 100%<br />

biodegradable, it turns into water and carbon dioxide in<br />

commercial composting.<br />

EcoWorks BioPlastic.indd 1 8/2/06 8:44:40<br />

bioplastics MAGAZINE [03/07] Vol. 2 33