bioplasticsMAGAZINE_0906

bioplasticsMAGAZINE_0906

bioplasticsMAGAZINE_0906

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Films | Flexibles | Bags<br />

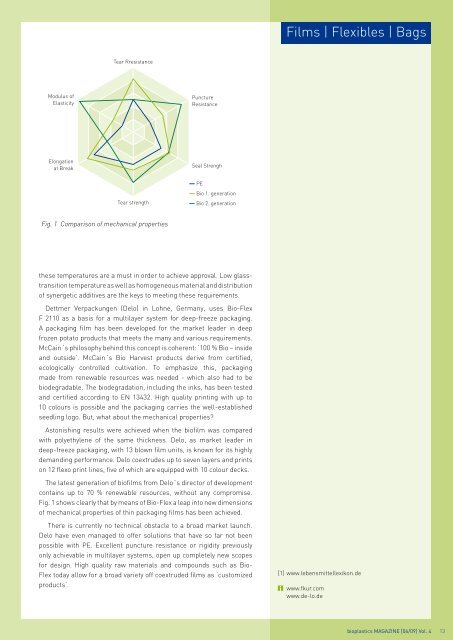

Tear Rresistance<br />

Modulus of<br />

Elasticity<br />

Puncture<br />

Resistance<br />

Elongation<br />

at Break<br />

Seal Strengh<br />

Tear strength<br />

— PE<br />

— Bio 1. generation<br />

— Bio 2. generation<br />

Fig. 1 Comparison of mechanical properties<br />

these temperatures are a must in order to achieve approval. Low glasstransition<br />

temperature as well as homogeneous material and distribution<br />

of synergetic additives are the keys to meeting these requirements.<br />

Dettmer Verpackungen (Delo) in Lohne, Germany, uses Bio-Flex<br />

F 2110 as a basis for a multilayer system for deep-freeze packaging.<br />

A packaging film has been developed for the market leader in deep<br />

frozen potato products that meets the many and various requirements.<br />

McCain´s philosophy behind this concept is coherent: ‘100 % Bio – inside<br />

and outside’. McCain´s Bio Harvest products derive from certified,<br />

ecologically controlled cultivation. To emphasize this, packaging<br />

made from renewable resources was needed - which also had to be<br />

biodegradable. The biodegradation, including the inks, has been tested<br />

and certified according to EN 13432. High quality printing with up to<br />

10 colours is possible and the packaging carries the well-established<br />

seedling logo. But, what about the mechanical properties?<br />

Astonishing results were achieved when the biofilm was compared<br />

with polyethylene of the same thickness. Delo, as market leader in<br />

deep-freeze packaging, with 13 blown film units, is known for its highly<br />

demanding performance. Delo coextrudes up to seven layers and prints<br />

on 12 flexo print lines, five of which are equipped with 10 colour decks.<br />

The latest generation of biofilms from Delo´s director of development<br />

contains up to 70 % renewable resources, without any compromise.<br />

Fig. 1 shows clearly that by means of Bio-Flex a leap into new dimensions<br />

of mechanical properties of thin packaging films has been achieved.<br />

There is currently no technical obstacle to a broad market launch.<br />

Delo have even managed to offer solutions that have so far not been<br />

possible with PE. Excellent puncture resistance or rigidity previously<br />

only achievable in multilayer systems, open up completely new scopes<br />

for design. High quality raw materials and compounds such as Bio-<br />

Flex today allow for a broad variety off coextruded films as ‘customized<br />

products‘.<br />

[1] www.lebensmittellexikon.de<br />

www.fkur.com<br />

www.de-lo.de<br />

bioplastics MAGAZINE [06/09] Vol. 4 13