WiN woodworking INTERNATIONAL 2022/1

WiN - woodworking INTERNATIONAL is the international magazine for the woodworking industry. We report on all aspects of woodworking from board materials, wood treatment to machines, tools and technical know-how, from timber engineering supplies to the latest developments in technologies and markets.

WiN - woodworking INTERNATIONAL is the international magazine for the woodworking industry. We report on all aspects of woodworking from board materials, wood treatment to machines, tools and technical know-how, from timber engineering supplies to the latest developments in technologies and markets.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

From single tool to product family<br />

T +49 2961 7405-0<br />

hello@rembe.de<br />

When sizing panel material, tools are usually used that are loud and heavy due to their<br />

structural design. The result is stress for man and machine. More than ten years ago,<br />

Leitz developed the pioneering tool solution for this problem that still sets the standard<br />

in terms of sustainability, efficiency and quality in edgebanding: the lightweight<br />

and quiet Diamaster WhisperCut jointing cutterhead. In the meantime, the world market<br />

leader from Oberkochen has turned it into a complete system family. With the available<br />

product variants, including one with an integrated HSK 32 R adaptor, users will in future<br />

be able to optimize existing jointing concepts and also optimize their production costs.<br />

Made<br />

in<br />

Germany<br />

significantly reduced compared to conventional<br />

systems. A solution that can be described as efficient<br />

in all respects.<br />

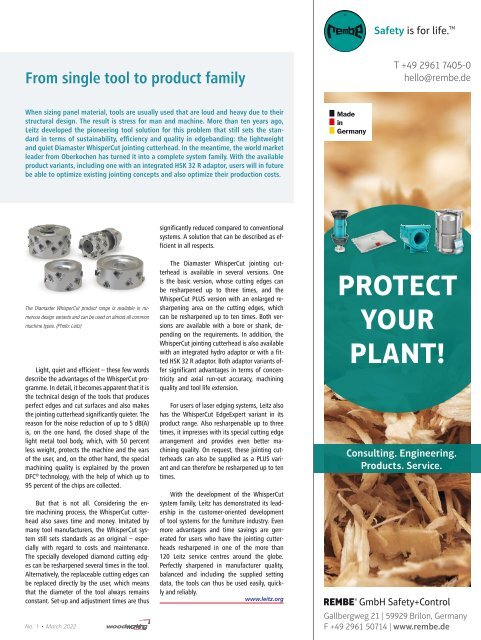

The Diamaster WhisperCut product range is available in numerous<br />

design variants and can be used on almost all common<br />

machine types. (Photo: Leitz)<br />

Light, quiet and efficient – these few words<br />

describe the advantages of the WhisperCut programme.<br />

In detail, it becomes apparent that it is<br />

the technical design of the tools that produces<br />

perfect edges and cut surfaces and also makes<br />

the jointing cutterhead significantly quieter. The<br />

reason for the noise reduction of up to 5 dB(A)<br />

is, on the one hand, the closed shape of the<br />

light metal tool body, which, with 50 percent<br />

less weight, protects the machine and the ears<br />

of the user, and, on the other hand, the special<br />

machining quality is explained by the proven<br />

DFC ® technology, with the help of which up to<br />

95 percent of the chips are collected.<br />

But that is not all. Considering the entire<br />

machining process, the WhisperCut cutterhead<br />

also saves time and money. Imitated by<br />

many tool manufacturers, the WhisperCut system<br />

still sets standards as an original – especially<br />

with regard to costs and maintenance.<br />

The specially developed diamond cutting edges<br />

can be resharpened several times in the tool.<br />

Alternatively, the replaceable cutting edges can<br />

be replaced directly by the user, which means<br />

that the diameter of the tool always remains<br />

constant. Set-up and adjustment times are thus<br />

No. 1 • March <strong>2022</strong><br />

The Diamaster WhisperCut jointing cutterhead<br />

is available in several versions. One<br />

is the basic version, whose cutting edges can<br />

be resharpened up to three times, and the<br />

WhisperCut PLUS version with an enlarged resharpening<br />

area on the cutting edges, which<br />

can be resharpened up to ten times. Both versions<br />

are available with a bore or shank, depending<br />

on the requirements. In addition, the<br />

WhisperCut jointing cutterhead is also available<br />

with an integrated hydro adaptor or with a fitted<br />

HSK 32 R adaptor. Both adaptor variants offer<br />

significant advantages in terms of concentricity<br />

and axial run-out accuracy, machining<br />

quality and tool life extension.<br />

For users of laser edging systems, Leitz also<br />

has the WhisperCut EdgeExpert variant in its<br />

product range. Also resharpenable up to three<br />

times, it impresses with its special cutting edge<br />

arrangement and provides even better machining<br />

quality. On request, these jointing cutterheads<br />

can also be supplied as a PLUS variant<br />

and can therefore be resharpened up to ten<br />

times.<br />

With the development of the WhisperCut<br />

system family, Leitz has demonstrated its leadership<br />

in the customer-oriented development<br />

of tool systems for the furniture industry. Even<br />

more advantages and time savings are generated<br />

for users who have the jointing cutterheads<br />

resharpened in one of the more than<br />

120 Leitz service centres around the globe.<br />

Perfectly sharpened in manufacturer quality,<br />

balanced and including the supplied setting<br />

data, the tools can thus be used easily, quickly<br />

and reliably.<br />

www.leitz.org<br />

© REMBE® | All rights reserved<br />

PROTECT<br />

YOUR<br />

PLANT!<br />

Consulting. Engineering.<br />

Products. Service.<br />

Gallbergweg 21 | 59929 Brilon, Germany<br />

F +49 2961 50714 | www.rembe.de