Separator's Digest - GEA Westfalia Separator Group

Separator's Digest - GEA Westfalia Separator Group

Separator's Digest - GEA Westfalia Separator Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

the year 2020 is under discussion. taxes will<br />

also be raised in parallel. Mineral oil tax will<br />

be charged at the full rate for biodiesel and<br />

vegetable oil used as fuel starting in 2012.<br />

the original subsidies for organic fuels have<br />

thus been abolished.<br />

Long-standing<br />

process know-how<br />

in Germany, the corresponding biodiesel<br />

production capacities have already been<br />

expanded in recent years. <strong>GEA</strong> <strong>Westfalia</strong><br />

separator has been very much involved in<br />

this process both as a supplier of standalone<br />

machines as well as a supplier for the<br />

entire core equipment of biodiesel factories.<br />

in the process of manufacturing biodiesel,<br />

vegetable oil is mixed with methanol and<br />

various reagents as catalysts; the ester<br />

compounds of the vegetable oil triglycerides<br />

are separated and the fatty acids which<br />

are generated are transesterified with the<br />

methanol. the glycerine obtained in this<br />

process is separated from the biodiesel.<br />

special separators are used for this stage.<br />

this main process is connected with the<br />

pre-treatment of the vegetable oil, also<br />

using separators. <strong>GEA</strong> <strong>Westfalia</strong> separator<br />

uses the familiar Cd process (Connemann<br />

AdM system) for recovering biodiesel; in<br />

the pre-treatment stage, <strong>GEA</strong> <strong>Westfalia</strong><br />

separator has extended this method to<br />

include alcoholic neutralisation of the free<br />

fatty acids with the glycerine obtained from<br />

the transesterification process.<br />

the subsequent recovery of methanol<br />

by means of rectification and glycerine<br />

water concentration are purely thermal<br />

processes, which however have also been<br />

supplied by <strong>GEA</strong> <strong>Westfalia</strong> separator as<br />

part of the overall process support. thanks<br />

to its extensive know-how and long-<br />

standing involvement in biodiesel technology,<br />

<strong>GEA</strong> <strong>Westfalia</strong> separator was in many cases<br />

responsible for the entire engineering. this<br />

makes sense particularly in view of the fact<br />

that interface problems were circumvented<br />

with the closely linked process stages.<br />

<strong>GEA</strong> <strong>Westfalia</strong> separator generally worked<br />

with local companies for producing the<br />

peripheral equipment, for instance steam<br />

generation.<br />

Rapeseed, soy,<br />

palm and sunflower oil<br />

in Germany rapeseed oil is still the main<br />

primary substance used in the production<br />

of biodiesel, with an oil content in the seeds<br />

of 40 to 45 percent. the agricultural surface<br />

requirement is around 10 square metres<br />

for each litre of diesel equivalent. on the<br />

other hand, in other countries of Europe,<br />

soy oil and a mixture of soy oil and palm<br />

oil are now more prevalent. sunflower oil<br />

is however also used in countries such as<br />

romania and Bulgaria. there is still backlog<br />

demand for biodiesel installations in poland<br />

and Greece for instance.<br />

in addition, in south America, and<br />

particularly in Brazil and Argentina with their<br />

huge soy plantations, there is an increasing<br />

trend for biodiesel to be produced for<br />

export. in parallel, the capacities of the<br />

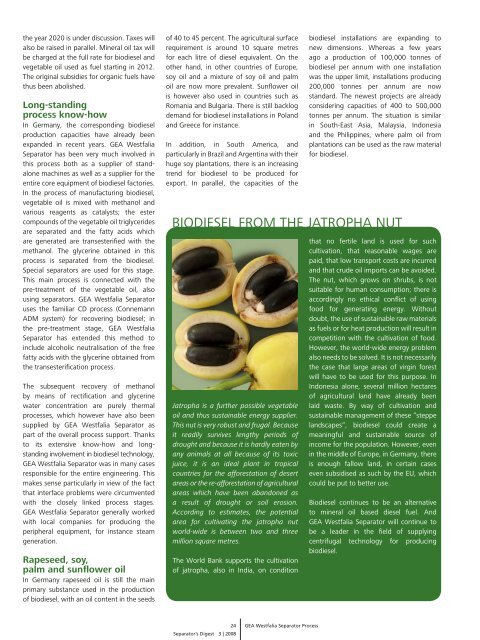

Jatropha is a further possible vegetable<br />

oil and thus sustainable energy supplier.<br />

This nut is very robust and frugal. Because<br />

it readily survives lengthy periods of<br />

drought and because it is hardly eaten by<br />

any animals at all because of its toxic<br />

juice, it is an ideal plant in tropical<br />

countries for the afforestation of desert<br />

areas or the re-afforestation of agricultural<br />

areas which have been abandoned as<br />

a result of drought or soil erosion.<br />

According to estimates, the potential<br />

area for cultivating the jatropha nut<br />

world-wide is between two and three<br />

million square metres.<br />

the World Bank supports the cultivation<br />

of jatropha, also in india, on condition<br />

biodiesel installations are expanding to<br />

new dimensions. Whereas a few years<br />

ago a production of 100,000 tonnes of<br />

biodiesel per annum with one installation<br />

was the upper limit, installations producing<br />

200,000 tonnes per annum are now<br />

standard. the newest projects are already<br />

considering capacities of 400 to 500,000<br />

tonnes per annum. the situation is similar<br />

in south-East Asia, Malaysia, indonesia<br />

and the philippines, where palm oil from<br />

plantations can be used as the raw material<br />

for biodiesel.<br />

BiodiEsEl froM thE jAtrophA nut<br />

24<br />

<strong>Separator</strong>’s <strong>Digest</strong> 3 | 2008<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> Process<br />

that no fertile land is used for such<br />

cultivation, that reasonable wages are<br />

paid, that low transport costs are incurred<br />

and that crude oil imports can be avoided.<br />

the nut, which grows on shrubs, is not<br />

suitable for human consumption; there is<br />

accordingly no ethical conflict of using<br />

food for generating energy. Without<br />

doubt, the use of sustainable raw materials<br />

as fuels or for heat production will result in<br />

competition with the cultivation of food.<br />

however, the world-wide energy problem<br />

also needs to be solved. it is not necessarily<br />

the case that large areas of virgin forest<br />

will have to be used for this purpose. in<br />

indonesia alone, several million hectares<br />

of agricultural land have already been<br />

laid waste. By way of cultivation and<br />

sustainable management of these “steppe<br />

landscapes“, biodiesel could create a<br />

meaningful and sustainable source of<br />

income for the population. however, even<br />

in the middle of Europe, in Germany, there<br />

is enough fallow land, in certain cases<br />

even subsidised as such by the Eu, which<br />

could be put to better use.<br />

Biodiesel continues to be an alternative<br />

to mineral oil based diesel fuel. And<br />

<strong>GEA</strong> <strong>Westfalia</strong> separator will continue to<br />

be a leader in the field of supplying<br />

centrifugal technology for producing<br />

biodiesel.